Horizon Microtechnologies - PRECISION MICRO-AM AND PROPRIETARY COATINGS TO MAKE NEXT GENERATION MM-WAVE PARTS AND COMPONENTS

Horizon Microtechnologies is sharing this Whitepaper with focus on Waveguide-based RF and its various applications

INTRODUCTION

Waveguide-based RF (Radio Frequency) components are specialised structures used to guide electromagnetic waves from one point to another with minimal loss of energy while (often) also performing, among others, additional functions such as polarisation discrimination, spectral filtering, and splitting. These waveguides are typically hollow tubes with highly conductive inside surfaces, such as those traditionally made from metals like copper or aluminum, designed to efficiently channel RF signals. The design of such waveguides ensures that electromagnetic waves are confined within the tube, preventing them from dissipating into the surrounding environment.

Waveguide-based RF components are widely used in various applications where efficient transmission of RF signals is crucial. Common examples include microwave communication systems, radar systems, satellite communications, sensing applications, and even in the medical field for certain imaging technologies. Specific components that utlise waveguides include directional couplers, which split signals; and filters, which allow certain frequencies to pass while blocking others.

Essentially, the effectiveness of waveguide-based RF components lies in their simple yet powerful design as hollow tubes with conductive surfaces and precisely determined dimensions, which optimally guide signals of a given frequency range with minimal loss and distortion, ensuring high-performance communication and signal processing.

Introducing features inside waveguides, such as lamellas (thin metal plates or structures), ridges, irises, or minute holes in a wall between two adjacent waveguides , significantly expands the functionality of these components, allowing for the implementation of complex RF devices like

filters, Orthomode Transducers (OMTs), and directional couplers.

By carefully designing and positioning these internal features, engineers can manipulate the electromagnetic waves traveling through the waveguide to achieve desired signal processing characteristics. For example, filters can be created by adding periodic structures that resonate at specific frequencies, selectively allowing certain frequencies to pass while reflecting or attenuating others.

This is particularly useful in communication systems where it is necessary to isolate and manage different frequency bands efficiently.

Orthomode Transducers (OMTs)

are used to separate or combine orthogonal polarisations of electromagnetic waves within a branched waveguide with 3 or more ports. By incorporating lamellas or other internal structures that are sensitive to the polarisation of the waves, OMTs can direct waves to different ports depending on their polarisation. This capability is essential in satellite communication and radar systems, where it is necessary to handle multiple polarisation states independently to maximise the efficiency and capacity of the communication channels.

Directional Couplers

which are critical in monitoring and managing signal flow, also benefit from the introduc;on of internal features within waveguides. These devices typically involve placing a series of lamellas or slots at specific intervals along the waveguide. The placement and design of these internal features cause a fraction of the power traveling through the main waveguide to be coupled into an adjacent waveguide. This mechanism allows for the sampling of the signal without significantly disturbing the main signal path, enabling functions such as signal monitoring or power splittng. Overall, the strategic integration of internal features like lamellas within waveguides transforms these simple hollow tubes into sophisticated RF components

capable of performing a wide range of signal processing tasks.

Manufacturing Waveguide-Based RF Components

with traditional production technologies presents several significant challenges, particularly when dealing with the high precision and tolerances required for effective performance. One of the primary issues is the necessity for extremely tight tolerances.

For instance, at D-Band frequencies, a tolerance of 33 micrometers is considered the least demanding.

Achieving such precision consistently is difficult with conventional machining techniques, as any deviation can significantly impact the performance of the waveguide by causing signal loss or reflection.

Traditional machining processes often struggle with maintaining these stringent tolerances over the entire length of the waveguide, leading to potential inconsistencies in the component's performance.

Another major challenge is the difficulty of machining complex internal features into solid metal tubes. As we have seen, many advanced RF components require intricate internal structures, such as lamellas, to achieve specific signal processing func;ons.

Traditional machining processes, such as milling or drilling, are not well-suited for creating these detailed features inside a solid tube. The inability to directly access the internal surfaces makes it nearly impossible to machine these features accurately. This limitation often forces manufacturers to use alternative methods, such as assembling the waveguide from two halves in a process known as split-block technology.

While split-block technology allows for better access to the internal surfaces, it introduces its own set of challenges.

The process involves meticulous assembly and bonding of the two halves to ensure that the internal features align perfectly, which is critical for the waveguide to function correctly. Any misalignment or gap between the halves can result in signal degradation or interference, compromising the performance of the RF component. The complexity and precision required in these manufacturing steps make it a highly specialised and often costly process.

Traditional manufacturing processes are also time-consuming and labour-intensive. The need for high precision means that each component requires careful inspection and quality control, adding to the production time and cost. Advanced manufacturing techniques, such as CNC

machining, can help mitigate some of these issues, but they still face limitations in achieving the necessary tolerances and intricate internal features. As a result, the production of these components remains challenging, prompting the industry to explore alternative manufacturing methods, such as additive manufacturing, which can potentially offer higher precision and flexibility in creating complex internal geometries.

MICRO-AM and COATING

Using plastic micro additive manufacturing (micro-AM) for waveguide-based RF components presents several key advantages, addressing many of the manufacturability challenges posed by traditional production methods. One of the primary benefits is the ability to achieve high precision and intricate geometries that are difficult or impossible to create with conventional machining.

Micro-AM processes can produce complex internal features, such as lamellas, with the required precision and consistency, ensuring optimal performance of the RF components. This precision is particularly crucial at high frequencies, such as D-Band, where even small deviations can significantly impact the component's functionality.

Micro-AM also facilitates component consolidation, allowing multiple parts to be manufactured as a single, integrated unit. This reduces the overall size and weight of the components, which is beneficial in applications where space and weight are at a premium, such as in aerospace and satellite communications. By eliminating the need for assembly of separate parts, micro-AM reduces the potential for performance deficits introduced by alignment tolerances. The precise control offered by micro-AM ensures that all features are perfectly aligned from the outset,

enhancing the reliability and performance of the final product.

One of the traditional drawbacks of using plastic — the material of choice for precision micro-AM — for RF components is its poor conductivity. However, this challenge can be effectively addressed using coating processes, such as those offered by Horizon Microtechnologies. By applying a metallic coating to the plastic components, the waveguide can achieve the necessary conductivity for efficient signal transmission. These coatings ensure that the plastic parts perform comparably to metal components while benefiting from the flexibility and precision of plastic micro-AM.

Horizon Microtechnologies' proprietary HMT-Metal coating applies copper or silver films with >30% of the bulk copper conductivity on complex shaped parts and a wide range of materials. The process can either coat the entire part’s surface, including internal channels and undercuts, or be applied selectively.

The HMT-Metal process is ideally suited for those applications where the use of bulk copper is not required and would be impossible or uneconomic. Using this process in combination with 3D printed plastic parts makes possible the production of previously unmanufacturable mm-wave components with sub-μm smooth surfaces which CNC machining or bulk metal 3D printing cannot deliver.

The design freedom afforded by micro-AM is another significant advantage. Engineers can explore new designs for filters, OMTs, and directional couplers that optimise performance and functionality. For example, complex internal structures that enhance signal filtering capabilities can be easily incorporated into the design without the constraints of traditional machining. This opens up opportunities for more efficient and compact RF components, tailored to specific applications and requirements.

In addition, the reduced need for assembly in micro-AM manufacturing translates to lower labour costs and faster production times. With fewer parts to assemble and align, the overall manufacturing process becomes more streamlined and efficient. This not only reduces the risk of human error during assembly but also shortens the time-to-market for new RF components. The ability to rapidly prototype and iterate designs using micro-AM further accelerates development cycles, allowing manufacturers to respond quickly to changing market demands and technological advancements.

Micro-AM also supports the production of lightweight components, which is particularly advantageous in aerospace and other on-the-move applications, where every gram counts. The reduced weight of plastic components, combined with the high conductivity of the applied coatings, results in high-performance waveguides that do not compromise on functionality.

This weight reduction can lead to improved energy efficiency and reduced operational costs in various applications.

So it can be seen that the use of plastic micro-AM, combined with Horizon Microtechnologies' proprietary coating processes, offers a revolutionary approach to the production of waveguidebased RF components. This method overcomes traditional manufacturing challenges, such as achieving high tolerances and machining complex internal features, while also providing benefits in terms of size, weight, and design flexibility. The integration of high-conductivity coatings ensures that the performance of plastic components matches that of their metal counterparts, paving the way for innovative designs and efficient production methods that meet the demands of modern RF applications.

MICRO-AM of CERAMIC & METALLISATION as a MEANS for FURTHER MINIATURISATION

In mm-wave components, ceramics other distinct advantages due to their combination of low dielectric loss and often very high permittivity. This allows them to be used as a filler material inside metallic waveguides that would otherwise contain air or vacuum. When used as such, their high permittivity leads to a reduced guided wavelength which allows for a significant reduction of the waveguide’s cross-section in contrast to the hollow

waveguide, promoting the miniaturisation of mm-wave systems.

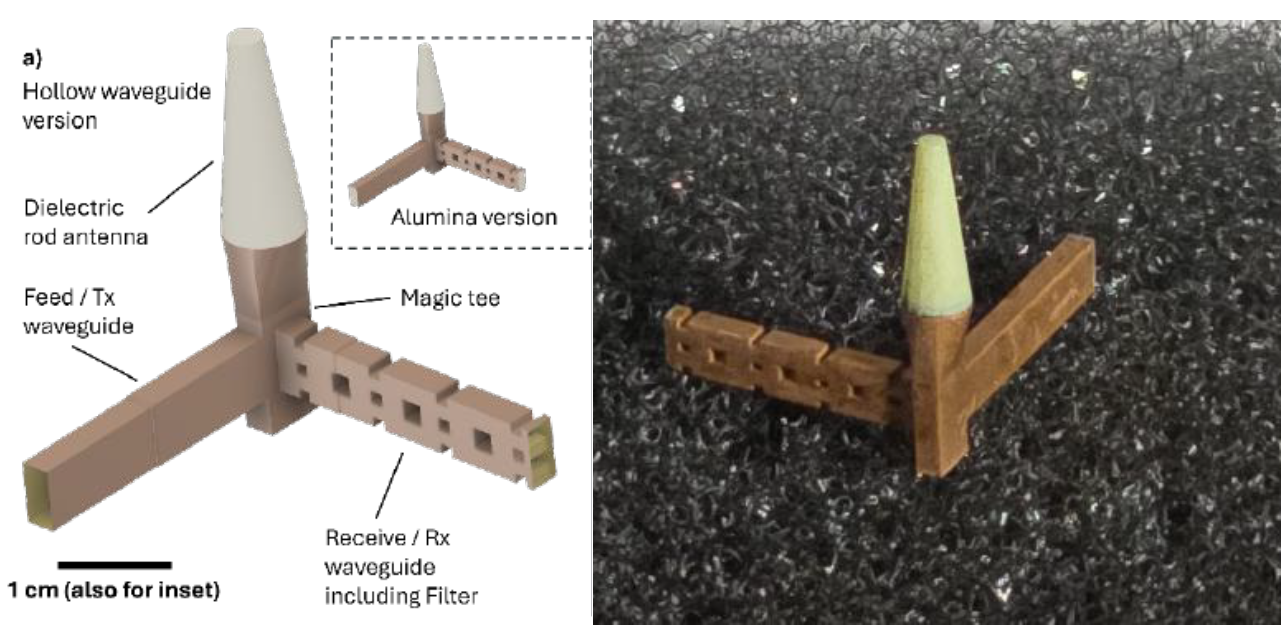

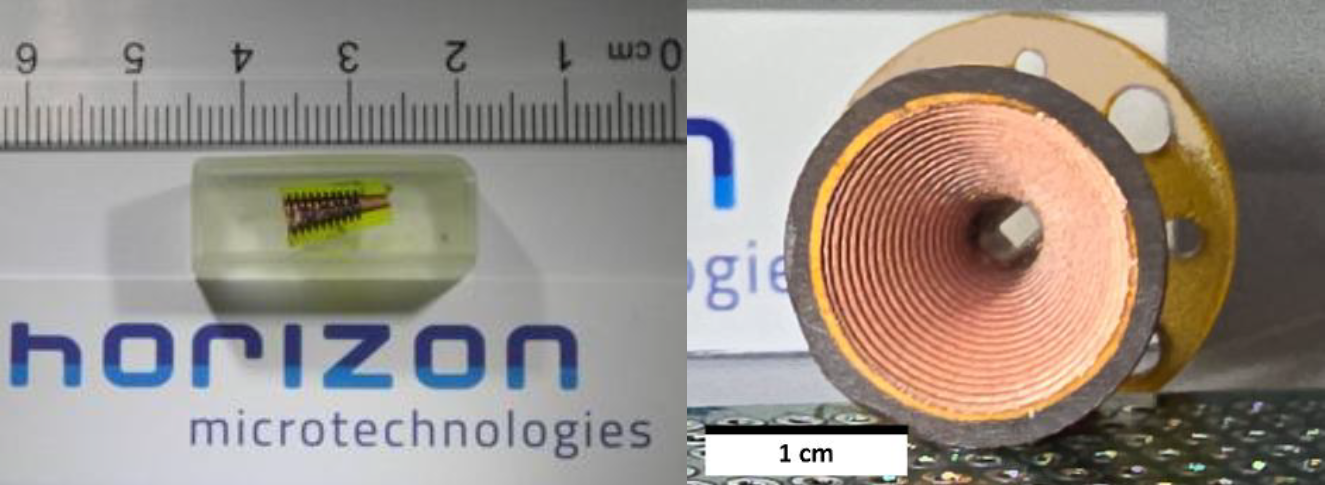

3D printing of ceramics o2ers a distinct approach to ceramic part manufacturing compared to traditional methods like injection moulding, machining, and casting, providing very high design flexibility. In order to exploit this for ceramic loaded waveguides, a 3D-capable method for the metallisation of the outside of the ceramic part is necessary, and this is specifically where the HMT-Metal process excels. The selectively metallised alumina demonstrator in the image below illustrates a combination of a feed waveguide joined to a receiving waveguide including a filter and a dielectric rod antenna using a magic-tee as a junction, e2ectively constituting a TxRx-Module. It monolithically integrates functions which would otherwise be facilitated by several traditionally made components in one part and is approximately 3 times smaller in all directions than an equivalent hypothetical hollow waveguide.

Left: Illustration of a hollow waveguide based design for a TxRx Module and a corresponding TxRx Module with air replaced by Alumina. Both devices are designed for the same frequency of 50 GHz but the Alumina version is more than 3x smaller.

Right: Metallised Alumina part.

CASE STUDY - AM-DERIVED SPLIT-BLOCK: WR10-WR12 WAVEGUIDE TRANSITION

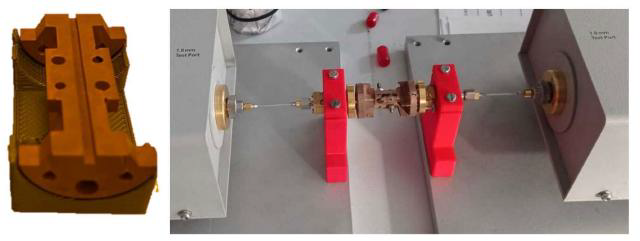

Currently, the HMT-Metal coating technology has limitations in coating extremely high aspect ratio channels, although advancements are continuously underway to push these limits. Even when the length of an internal channel prevents the use of a fully monolithic design, manufacturing a waveguide based design in two halves using micro-AM has benefits in terms of lead time and the ease of precisely manufacturing thin features additively rather than subtractively.

The channel on each half is then individually coated with the HMT-Metal process before being assembled into a complete unit. Testing results show that these split block and coated micro AM waveguides perform as well as traditionally made split block waveguides, as evidenced by the measurement data below. This hybrid process ensures that the intricate internal structures receive the necessary coating while still enabling the design freedom of AM to be exploited. As the technology progresses, it will soon be possible to coat longer and longer internal channels of any length in a single monolithic piece, further simplifying the manufacturing process and enhancing the capabilities of micro AM in producing waveguides.

Left: Half of a WR10-to-WR12 waveguide transition.

Right: Assembled WR10-to-WR12 waveguide transition during measurement.

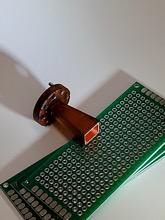

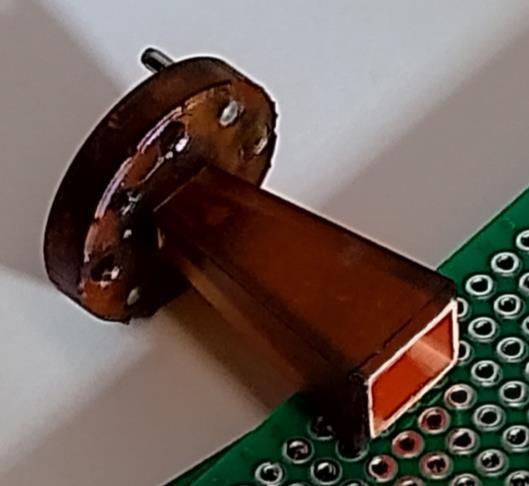

CASE STUDY - D-BAND HORN ANTENNA

Horizon Microtechnologies undertook rigorous functional testing to prove the effectiveness of its HMT-Metal coating process (with which copper and silver layers can be applied very evenly and conformally to a variety of component shapes and materials) for making high frequency D-Band

horn antenna via 3D printing. From a commercial perspective, such components fit well with the use of micro-AM as they are typically in the cm size range, with sub-mm dimensions, and require the aSainment of micron tolerances.

The market demands such antenna and other mm-wave components for higher and higher frequencies for use in industrial measurement technology, sensor technology and communication applications with very low latencies. Being able to make such mm-wave components via micro-AM allows the production of smaller and lighter weight components, and also opens up the possibility of making them with properties and geometric features impossible using alternative fabrication processes.

Standard 20 dBi gain horn for 110 GHz to 170 GHz made by Horizon Microtechnologies using micro-AM and metallic coating.

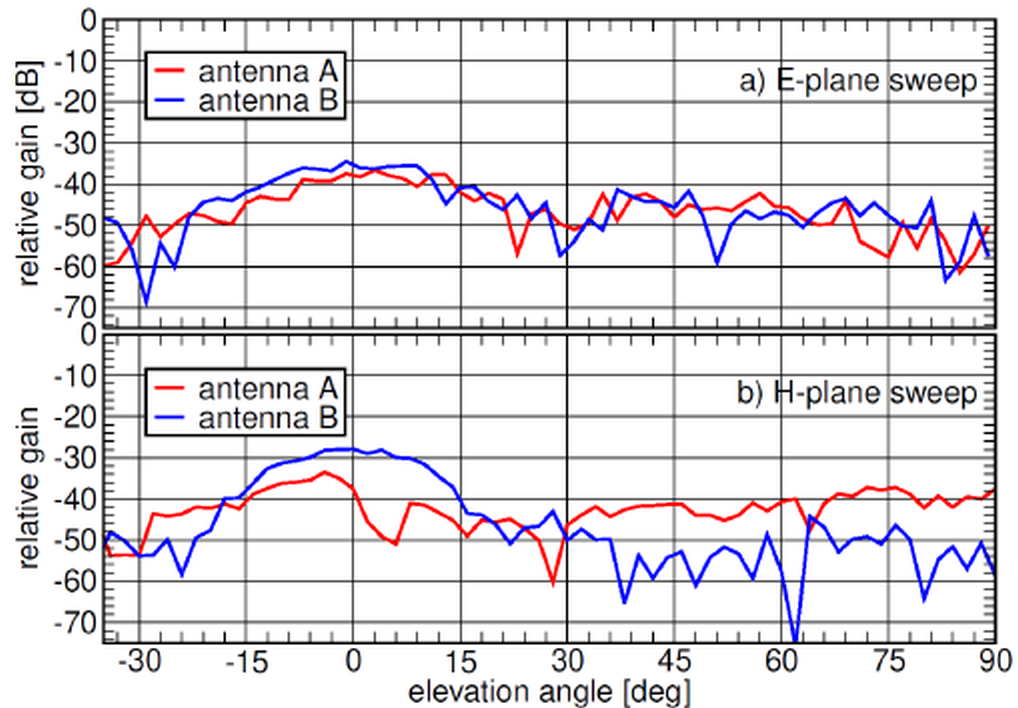

Cross polarisation measurement on two such antennas. In theory, the cross polarisa-on should be non-existant, hence the very low measured

values indicate the high quality of the antenna. BoQom: Radiation pattern of the antennas measured in the H-plane. The agreement with theory is very good. The return loss of the antennas is better than -24 dB over the entire frequency range and averages about -30 dB, again in excellent correlation with theory (not shown).

The performance of an antenna depends on a large number of component properties that are difficult to measure and calculate directly such as the conductivity of the metallic layers, layer thicknesses, layer thickness homogeneity, dimensional accuracy of the antenna, and surface roughness. Instead of an elaborate determination of all these properties, Horizon undertook a functional comparison of its copper coated micro-AM produced horn antenna with a traditionally produced commercially available antenna, a pragmatic approach which allowed Horizon to prove its manufacturing technology is sufficiently good to serve high frequency and antenna applications as well as or better than traditionally made components can.

Measurements were made of the radiation paSern (how much signal goes out of the antenna and in which direction) and the S11 parameter (how much of the signal is reflected back from the antenna into the transmitter). The directivity of the antenna (how much signal goes in the forward direction) and the S11 parameter can also be compared clearly and directly with traditionally produced antennas for which these are usually contained in the datasheets.

Successful testing should indicate a high gain value in the forward direction and as little backreflection as possible. Horizon’s micro-AM copper coated horn antenna performed as well as a conventionally built horn antenna, removing many of the reservations that 3D printed devices are often faced with.

Even more importantly, the variation from antenna to antenna was very low, and the measurement data on the antennas was near-indistinguishable from the results of computer simulations using the engineering CAD model without any further adaptions or tweaks to the model. This proves that some very interesting opportunities exist as companies requiring horn antennas and other mm-wave components can now exploit the process advantages of micro-AM by partnering with Horizon as their development and manufacturing partner. Horizon didn’t perform full-blown dedicated additive design-thinking efforts for the antenna since the company wanted to fabricate something emulating the conventional counterpart. Even so, the antenna weighs only a sixth of its conventional counterpart and takes up 15% less space.

This is a powerful indication of the kind of benefits that dedicated AM-based component design-thinking could achieve, and opens up the potential for easy customisation in short lead times for the mm-wave sector.

CASE STUDY - CORRUGATED HORN

Following the work on D-Band Horn antennas mentioned above, Horizon announced that through the use of its in-house plastic micro AM technology, it has successfully manufactured an “upgraded” version of such horns. Specifically, Horizon has printed a funnel-shaped horn with

internal corrugations, which was subsequently coated using its HMT-Metal coating process.

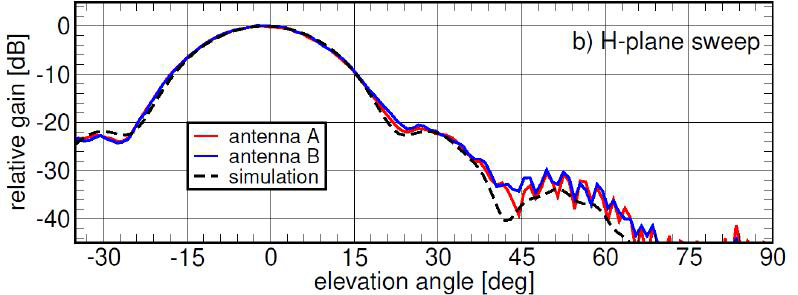

The image shows one half of a corrugated horn after embedding it in a transparent epoxy and sawing it in half to reveal the interior. (The bubbles visible in the protective epoxy are from the embedding procedure and not related to the metallisation process which has successfully coated the inside of the horn).

Corrugations inside a horn antenna introduce a significant enhancement in performance compared to traditional smooth-walled horn antennas. These corrugations effectively modify the antenna's boundary conditions and can be used, for example, to tailor the phase front for achieving highly directional beams with low sidelobe levels. By exploiting the additional design degree of freedom offered by the introduction of the corrugations, increased bandwidth, improved paSern symmetry and reduced cross-polarisation can be achieved.

These advantages make corrugated horns particularly valuable in applications requiring high precision and reliability in the radiation pattern and polarisation characteristics, such as satellite communications, radio astronomy, and radar systems, where signal integrity and performance consistency are critical.

Two examples of corrugated horn antenna made by 3D printing a polymeric body and subsequently coating the inside with high conductivity copper.

Left: Engineering sample of a corrugated horn designed for operation in the WR5 frequency range (140 GHz to 220 GHz) after embedding it in epoxy and cu[ng it open to reveal the interior.

Right: Corrugated horn with a mode transformer function. It implements a textbook transition from a round antenna aperture to the rectangular waveguide opening.

Horizon’s ability to make such “upgraded” horns via the addition of corrugations, protruding into the horn funnel via micro-AM and then coating them in metal is highly disruptive in the mmwave sector.

Such corrugations would be either impossible to achieve via machining or expensive and slow.

Horizon can reduce the production of such a corrugated horn to 3 weeks, whereas machinable corrugated horns usually have leadtimes of 8 weeks or more.

CONCLUSION

In light of the advantages discussed and supported by successful case studies, it has been demonstrated that micro-AM combined with Horizon Microtechnologies' proprietary coating processes produces waveguide-based RF components that are on par with traditional solid metal devices.

This innovative approach not only achieves the necessary high tolerances and conductivity but also significantly speeds up the production process. By leveraging micro-AM, manufacturers can produce intricate and precise internal features that are difficult or impossible to machine with conventional methods, resulting in high-performance components that meet the stringent demands of modern RF applications.

The introduction of previously unmachinable features through micro-AM also stimulates innovation in the design and functionality of waveguide-based RF components.

This design freedom allows for the creation of more efficient, compact, and lightweight components, opening up new possibilities for applications in fields such as telecommunications, aerospace, and medical imaging.

Overall, the combination of micro-AM and advanced coating technologies not only matches the performance of traditional manufacturing methods but also offers significant enhancements in production efficiency, cost-effectiveness, and design capabilities, driving forward the evolution of RF component technology.

ENDS

Related Articles

Horizon Microtechnologies - Seeking Coating Technician

Exploring Materials In 3D Printing: Metals, Ceramics, And Polymers