Advanced AME Equipment Enabling Surface Part Mounting Substrates

Concept

This AME design has the status of concept. A first design concept is established, a complete explanation of the targeted functionality is included, and the targeted printer technology has been provided.

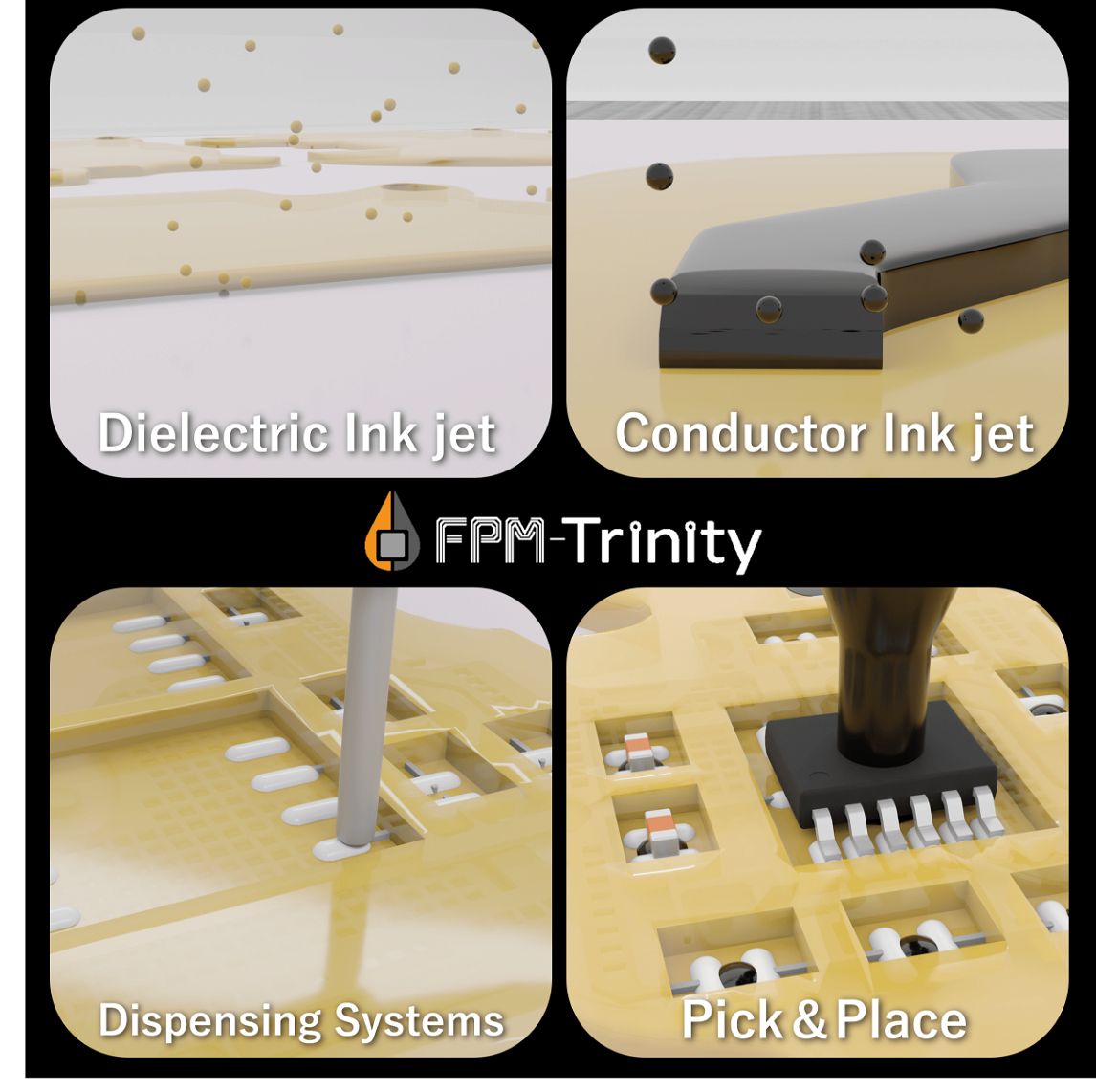

FPM-Trinity is not only for the creation of bare boards made with dielectric resin and conductive ink but also for the creation of boards with SMT parts.

FPM-Trinity: Rapid Substrate Creation in AME

In the field of Additively Manufactured Electronics, FPM-Trinity It is the only equipment that can create boards with SMT parts by combining a variety of materials and processes and can provide optimized parameters for those materials and processes.

Bare boards are created by using two ink jet systems that applies dielectric resin and conductive ink.

And additional two dispenser systems are used for the interconnection between the parts and boards. The first one is for silver paste for conductivity, and the second one is for epoxy glue for adhesion between the parts and boards. These specific processes have been established for the integration with AME process and it makes the substrates highly reliable.

All these processes are integrated into a single cell-type equipment. In addition, since all processes are digital printing and do not require mask tools, the substrates can be created in a single day simply by importing data into the equipment. FPM-Trinity is a very useful tool for users who want to make prototypes quickly.

Introduction of FPM-Trinity

All in one process for AME and SMT

Related Articles