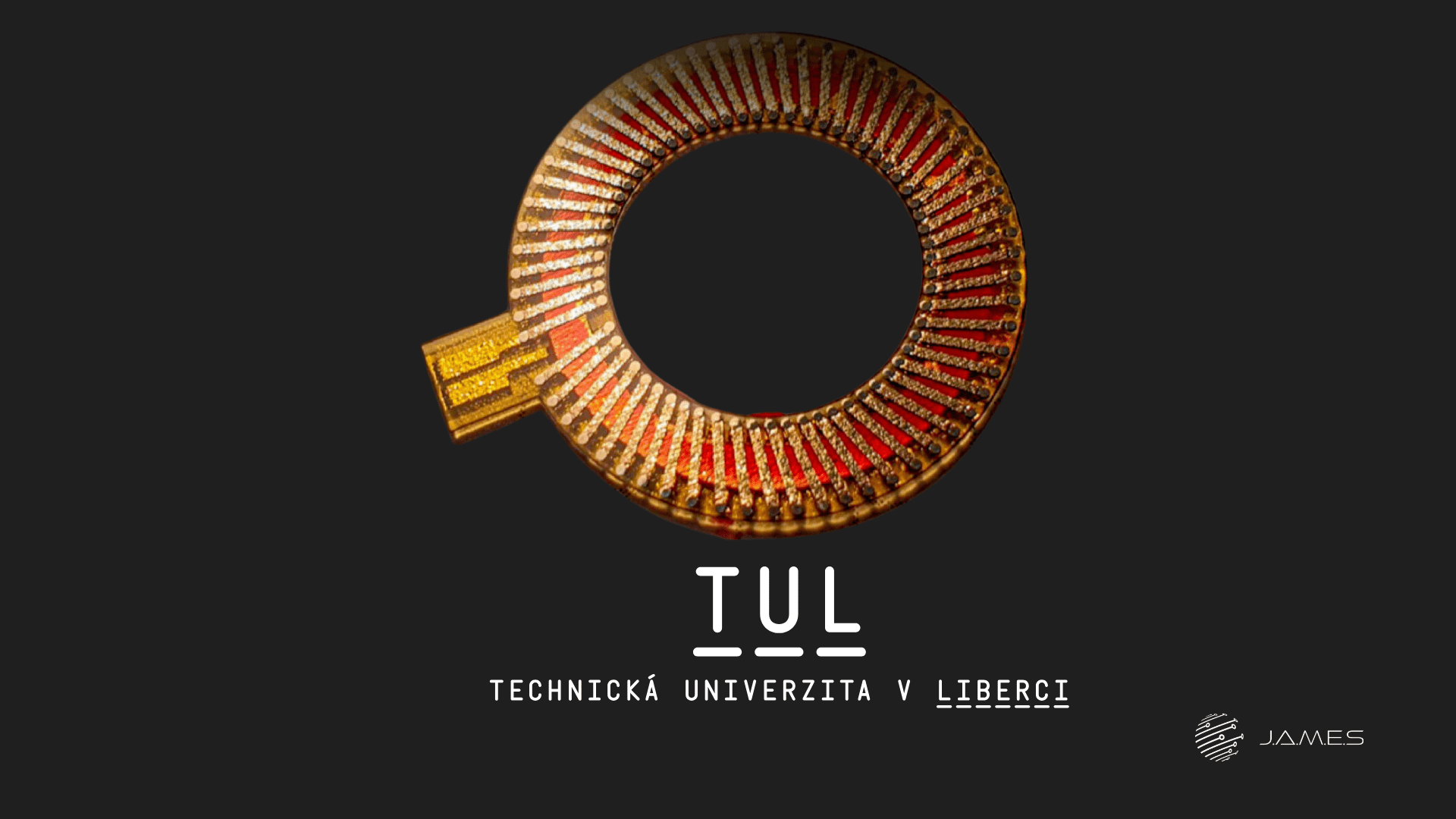

Embedded Parts: Fluxgate Sensor

The paper titled "Embedded Parts - Fluxgate Sensor" by Prof. Ing. Zdeněk Plíva, Ph.D., and Ing. Leoš Petržílka, in close collaboration with Nano Dimension (many thanks for strong support in developing the technology and printing namely to Amir Shelef and Aviram Iancovici), presents a case study on designing and manufacturing a fluxgate sensor using advanced 3D printing technology.

Overview

The case study describes a new method for constructing the fluxgate sensor using Nano Dimension's Dragonfly LDM 2.0 Additive Manufacturing System. The objective is to fabricate a sensor with the embedded coil core . This design may be realised by two methods for embedding the core: direct printing (currently not possible due to material constraints) and embedding metalic core during the print time into the printed cavity.

As explained, this allows more flexibility to design a coil using traditional eCAD software or 3D CAD systems. The coil embedding process is multi-staged, with a detailed description of each phase.

The developed fluxgate sensor shows superior performance, achieving a sensitivity of around 7,500 V/T at an excitation frequency of 29 kHz, with noise levels as low as 14 pT/√Hz using advanced shielding. Due to the success of the first-generation sensor, a second-generation design is now in development.

Key Aspects

- Innovative 3D Printers: The project showcases the versatility of Nano Dimension's Dragonfly LDM system and how it can be utilized for advanced additive manufacturing to develop intricate electronics with embedded elements.

- Design of an Embedded Coil: Two methods for embedding the coil core inside the sensor are proposed, focusing on using 3D printing technology to innovate the fabrication process for advanced electronics.

- Sensor Performance: It demonstrated high sensitivity and low noise levels, making it suitable for precise magnetic field measurements.

- Partnership: The joint project highlights how academic and industrial partnerships, like CTU in Prague and Nano Dimension, can drive innovation.