Voltera NOVA Applications: Printed Silver Tattoo Electrodes And Copper RFID Tag

Researchers and Voltera’s applications team have been pushing the limit of the direct-ink-writing (DIW) technology. This article explores two breakthroughs in flexible hybrid electronics driven by Voltera's NOVA materials dispensing system: printed silver tattoo electrodes and the use of nano copper ink for ultra-high-frequency RFID tags.

Printed Tattoo Electrodes for Biomedical Monitoring

Biomedical electrodes are essential for monitoring the body's internal processes by transforming biological signals into electrical data. However, traditional electrodes often come with drawbacks such as discomfort and movement interference.

Researchers like Yoland El-hajj at York University are revolutionizing this field with innovative solutions. By leveraging silver inks and comparing inkjet and extrusion printing techniques, El-hajj’s team has developed flexible, comfortable electrodes that naturally conform to the body. This cutting-edge approach promises to enhance medical procedures and drive exciting advancements in healthcare.

Using Voltera’s NOVA materials dispensing system, the team explored various designs to optimize performance and signal quality. El-hajj emphasized that the thinness of tattoo paper opens up numerous possibilities, including integration with prosthetic devices. NOVA streamlines the printing process, making material calibration and pattern alignment more precise and efficient, all while significantly reducing costs and production time compared to other methods like screen printing.

NOVA: Biomedical Silver Electrodes on Tattoo Paper

Discover why addivite electronics and NOVA were the ideal solution to develop printed biomedical electrode tattoos.

UHF RFID Tag Printed With Nano Copper Ink on Paper

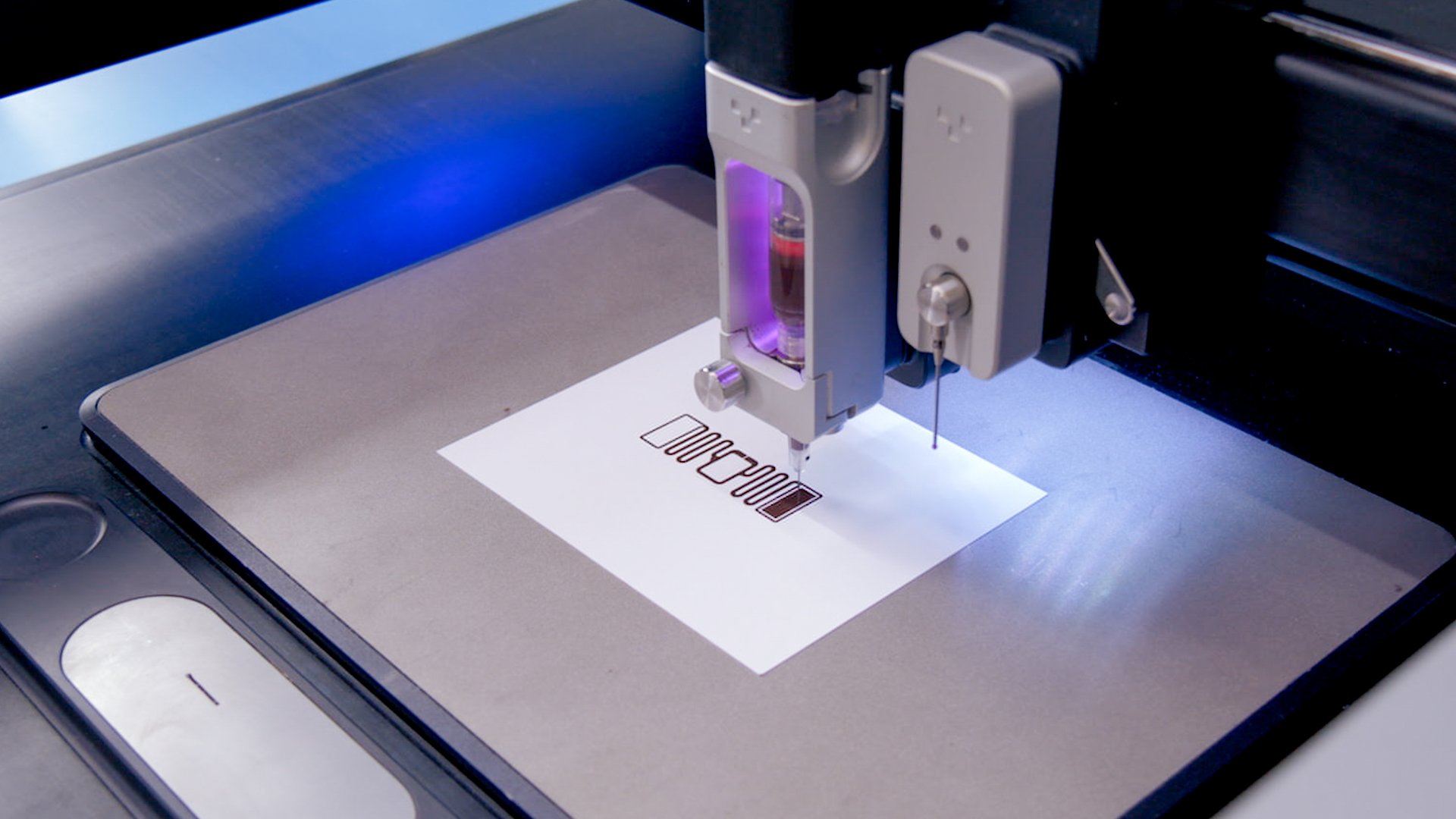

The Voltera team highlights the additive manufacturing process of an ultra-high frequency (UHF) RFID tag on paper using nano copper ink, which is more environmentally friendly compared to traditional methods.

Using the Voltera’s NOVA materials dispensing system, the team printed an RFID antenna on paper, resulting in a compostable, high-performance tag with lower production costs and waste. With a minimum self-reflection coefficient (S11) of -29.42 dB at 922.50 MHz, the custom-printed RFID tag even outperformed commercial alternatives.

The project showcases NOVA's capabilities for rapid prototyping of printed antennas, and the growing potential of nano copper inks in RFID or NFC applications.

More on NOVA’s Applications

To learn more about applications and studies involving NOVA, check out the following resources:

- Webinar: Printing Biomedical Sensors with NOVA

- White paper: Printing an RFID Tag with Copper Ink on Paper

- Customer story: Researching Printed Stretchable Bioelectronics with Voltera NOVA and V-One

- Research: Papers published using Voltera NOVA

Related Articles

Voltera V-One Webinar: Dispensing Solder Paste On Factory Fabricated PCBs

Nanomaterials In 3D Electronics Printing: Enabling Multi-Material Circuit Fabrication

Breadboards Vs. PCBs: Definitions, Materials, Costs, Benefits, And Applications