Advancing Flexible Hybrid Electronics Through High-Resolution Printing

The research paper titled "High-Resolution Printing-Based Vertical Interconnects for Flexible Hybrid Electronics" explores a pivotal innovation in Flexible Hybrid Electronics (FHE). Conducted by the Bendable Electronics and Sustainable Technologies (BEST) Group at Northeastern University, led by Ravinder Dahiya, the study emphasizes the development of resource-efficient and low-cost vertical interconnect access (VIA) technologies.

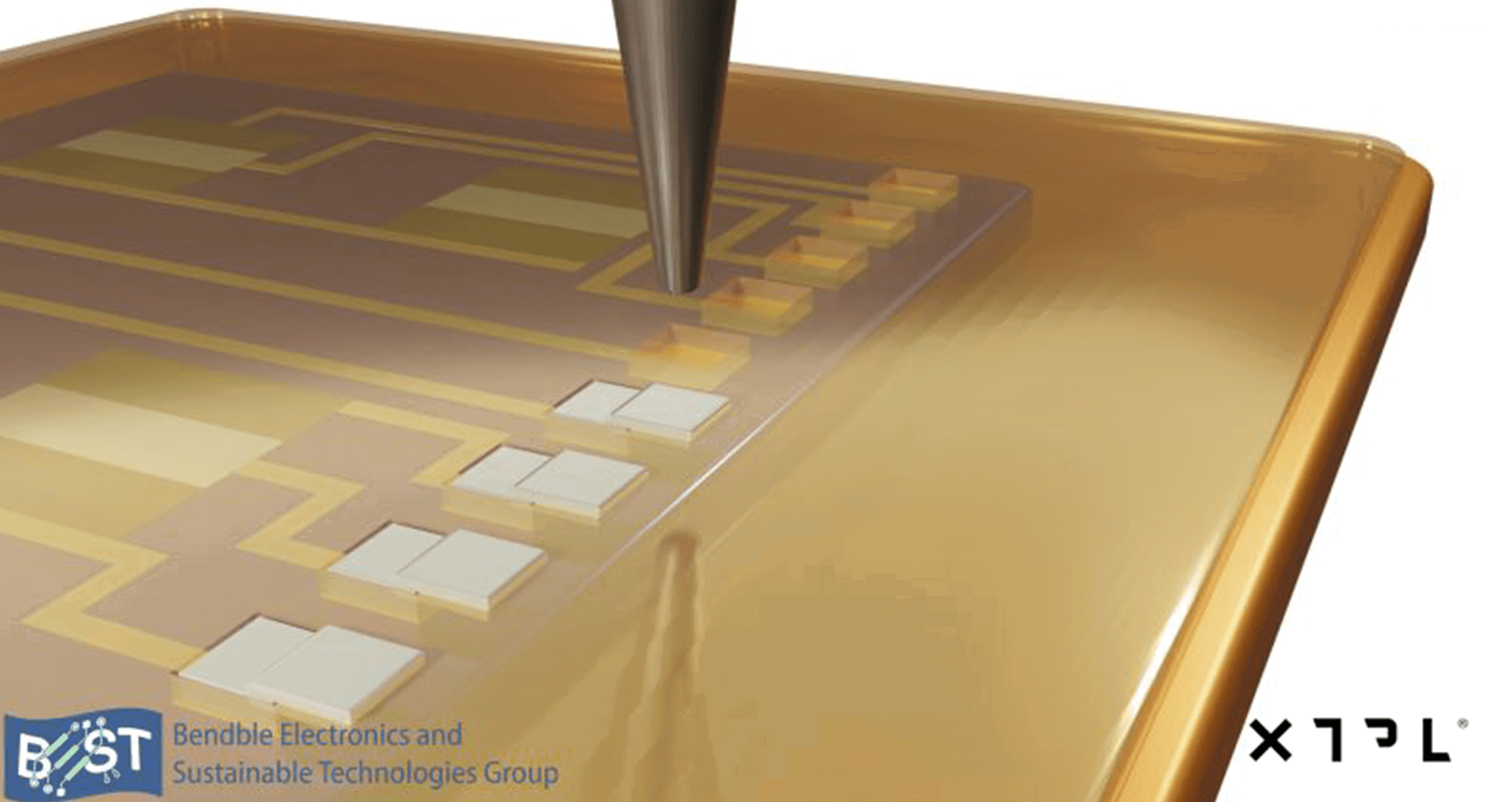

The BEST Group’s expertise in printed electronics and ultra-thin chip (UTC) integration underpins this research, addressing challenges in conventional bonding methods and enabling advanced applications in wearables, robotics, and IoT. By leveraging high-resolution electrohydrodynamic (EHD) and extrusion-based direct-ink writing (DIW) printers, the team introduces an innovative approach to creating reliable interconnects for flexible electronics.

Research Overview

The study investigates traditional bonding problems—differences in heat and mechanical stress—that have held up FHE development. The authors use high-resolution electrohydrodynamic (EHD) and extrusion-based direct-ink writing (DIW) printers to demonstrate improved methods for fabricating VIAs filled with conductive silver inks. This method achieves

- High-density integration with very little wasted material.

- Stable electric contacts under mechanical load.

- Improved compatibility with flexible materials through additive processes.

XTPL Technology's Role

This study focuses on the XTPL Delta Printing System, which is used in printing vertical connections. This system, in combination with silver nano-paste, creates consistent VIAs with low resistance. Unlike EHD printing, XTPL's extrusion printing does thicker, lower-resistance connections in fewer layers—a distinct show of efficiency and adaptability for FHE applications.

Key Findings

- Better Performance Stability: MOSFETs on UTCs with printed VIAs presented good electrical performance even under various bending conditions.

- Material and process efficiency: Printing technologies are faster and more resource-efficient than traditional methods, hence making them a good choice for high-density 3D FHE systems.

- Strength Under Strain: Devices were resilient when compressed or stretched, indicating that printed VIAs are fully functional under changing conditions.

Table of Contents

- Introduction

- Results and Discussion

- 2.1 UTC Thinning, Transfer, and Packaging

- 2.2 Vertical Interconnects Realization

- Conclusion

- Experimental Section

- Supporting Information

- Conflict of Interest

- Data Availability Statement

Related Articles

High Frequency Solution-processed Organic Field-effect Transistors With High-resolution Printed Short Channels

Breaking Update: J.A.M.E.S And XTPL Redefining 3D Manufacturing