Fully 3D Printed 2.4 GHz Bluetooth/Wi-Fi Antenna

This research paper "Fully 3D Printed 2.4 GHz Bluetooth/Wi-Fi Antenna," was written by Paul Deffenbaugh, Kenneth Church, Josh Goldfarb, and Xudong Chen.

Overview

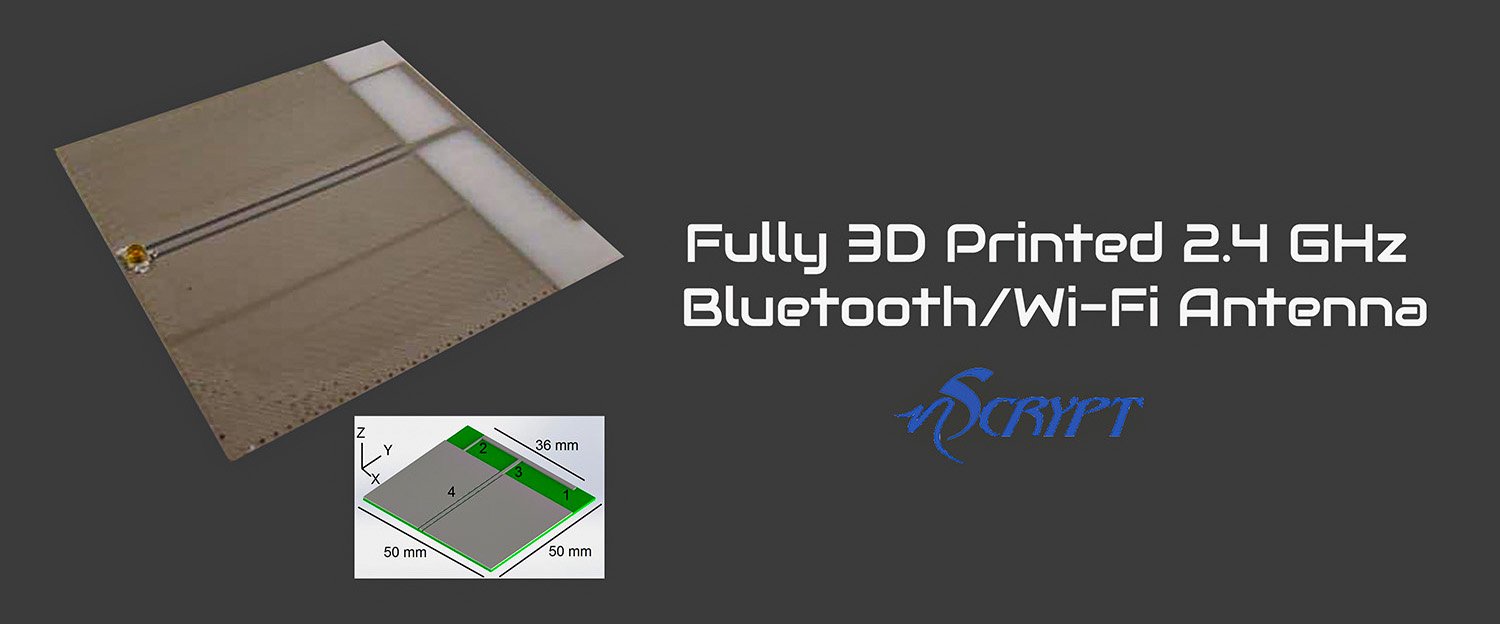

The work discusses the utilization of 3D printing in electrical RF device manufacturing and presents a proof-of-concept case on the development of a 2.4 GHz antenna for both Bluetooth and Wi-Fi applications using additive manufacturing [10]. In this work, an investigation is made of the amalgamation between mechanical and electrical characteristics to originate a distinctive 3D electrically structural device.

Methodology

IMDEA Networks Institute: This paper successfully shows the integration of 3D printing with printed electronics for fabrication of a 2.4 GHz antenna. The process uses 3D printing to produce both the dielectric materials (which double as a structural material) and conductors across three axes. The design and performance of the antenna is characterized by full-wave models created from Ansoft HFSS demonstration, as well as a real-world test with Class 1 "100 m" range Bluetooth module. This is then compared to a industry standard quarter wavelength monopole antenna.

Key Concepts

- 3D Printing and Additive Manufacturing (AM): Enable the fabrication of complex 3D structures in a layer-by-layer base, while integrating mechanical properties with electrical properties for functional devices.

- Events - Printed electronics: Making electronic functions on thin substrates like paper or plastic, often combined with 3D printing for RF devices.

- Fully 3D printed RF antenna: Proof of concept for a Bluetooth/Wi-Fi application in the ISM band operating at 2.4 GHz integrated into an all-printed structure with a combination of dielectric and conductive materials.

- This network of ANSYS HFSS modeling software: Enabled the user to conduct analyses and accurately predict how printed antenna performance compared with traditionally designed antennas.

- IFA (Inverted F Antenna) Design: A particular design of antenna used for its omni-directionality and efficiency, often found in cell phones or other wireless devices.

- nScrypt's SmartPump Technology: This pump allows the printing of 3D features as small as human cells by precisely dispensing highly conductive inks, proving to be essential for functional electronic part fabrication.

- Dielectric and Conductor Integration: The use of multiple materials to create a structure that can serve as an insulator, but which also contains electrical functions in 3D printing.

Table of Contents

-

Abstract

-

Introduction

-

3D Printing and Printed Electronics

-

Printed RF Antenna on Liquid Crystal Polymer (LCP) Substrate

-

Antenna Design for Bluetooth

-

Modeling

-

Structural Dielectric Fabrication

-

Conductor Fabrication

-

Testing

-

Conclusion

-

Acknowledgment

-

References

Related Articles

Enhancing Electrical High-frequency Performance By An Optimized Additive Manufacturing Strategy