Flexible Quantum-Dot Light-Emitting Diodes Using Embedded Silver Mesh Transparent Electrodes Manufactured By An Ultraprecise Deposition Method

Qualified

A first design is finished, a complete explanation of the targeted functionality is included, and the targeted printer technology has been provided. This AME design also provides a model which is proven to fulfill the targeted functionality. Furthermore, the AME structure has been printed and validated by measurements. A complete set of the measurement setup and results is provided. This AME design is part of a system that has reached product level and has passed a specified set of environmental tests. The specifications of the performed tests and the results are provided.

Flexible substrates with transparent conductive electrodes (TCEs) are essential components of organic-light-emitting diodes (OLEDs). However, Indium tin oxide (ITO), the prevailing transparent and conductive electrode material, is ill-suited for flexible devices due to its brittleness.

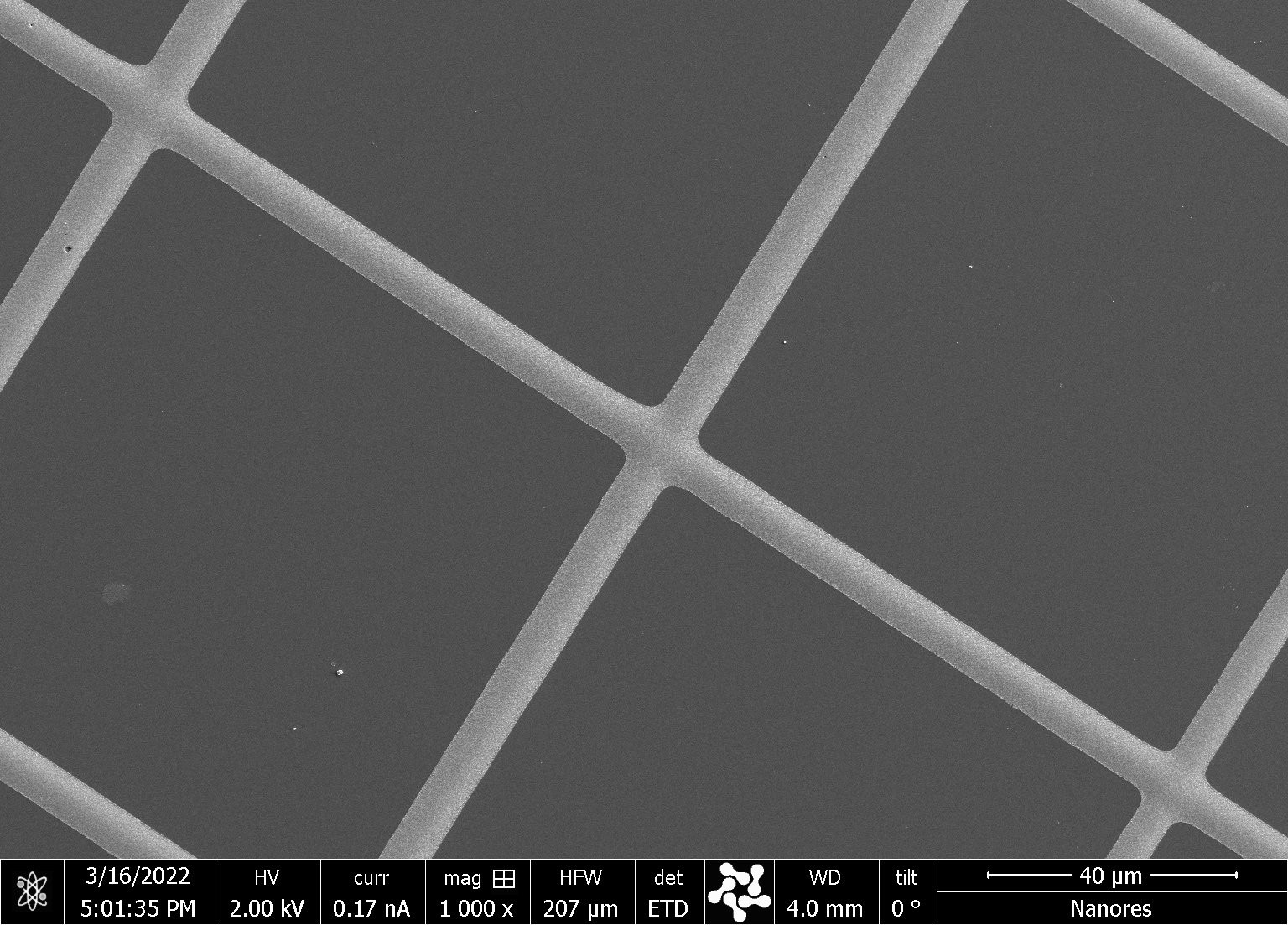

Łukasz Witczak, Mateusz Łysień, Artur Podhorodecki, Piotr Sitarek & Maciej Chrzanowski introduced a new method for producing flexible, transparent, and conductive electrodes for optoelectronic purposes using a silver metal mesh and ultraprecise deposition (UPD) technique.

Fabricated mesh exhibits:

🟢 an 80% (λ = 550 nm) optical transmittance

🟢 a sheet resistance of 11 Ω/sq.

To evaluate its performance, the polymer-embedded Ag-mesh is utilized as an anode in a quantum-dot light-emitting diode (QLED). The fabricated QLED is characterized by:

🟢 the maximum external quantum efficiency (EQE) of 2%

🟢 a current efficiency (CE) of 6 cd/A,

🟢 reaching the maximum luminance (L) of 3200 cd/m2 at a current density of 100 mA/cm2.

This method offers a convenient and fast way to create optoelectronic devices, without the need for any specialized equipment or complicated treatments.

Read the whole article!

➡️ Publication

Related Articles

Revolutionizing Display Manufacturing: The Impact Of XTPL’s Ultra-precise Dispensing Technology

Design And Performance Of Additively Manufactured In-Circuit Board Planar Capacitors

Cube Satellites: Paving The Way For The Future Of Space Activities