Nano Dimension

Why Nano Dimension? We're Reinventing Manufacturing

A provider of intelligent machines for the fabrication of Additively Manufactured Electronics.

Latest Articles

Partnership News

Nano Insights - AME and J.A.M.E.S

Build, Test, Iterate Electronics in a Single Day

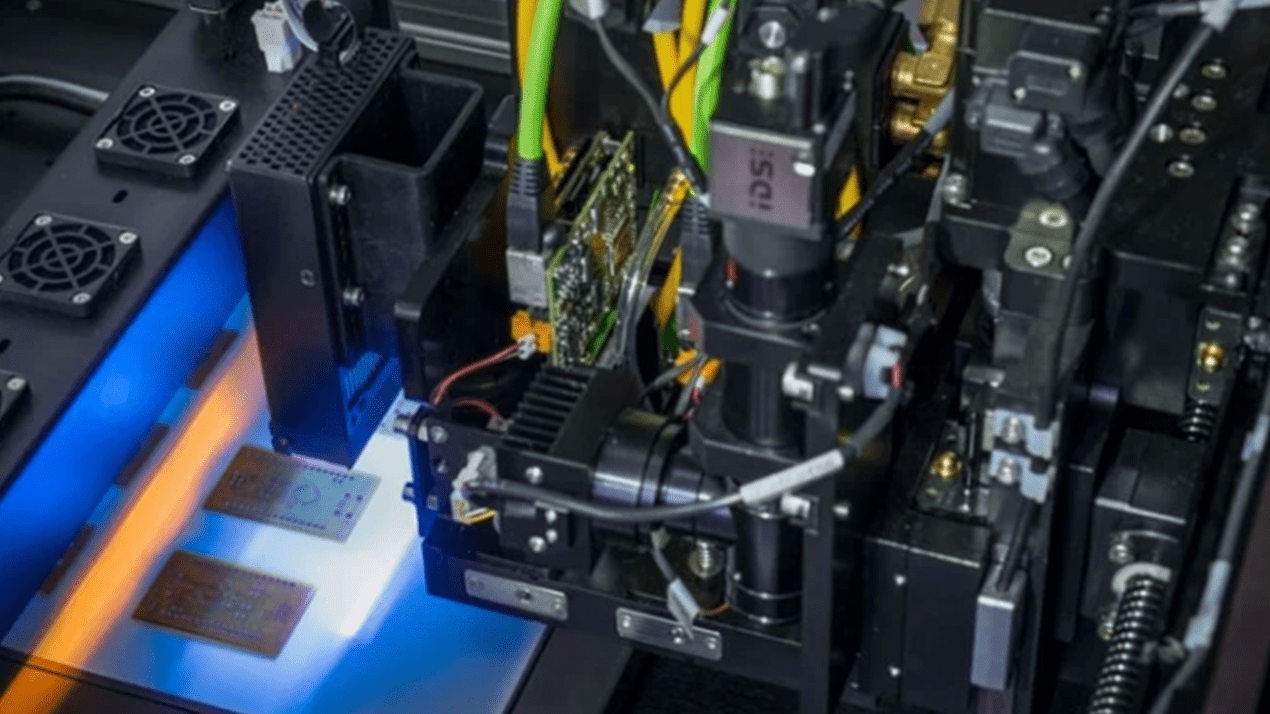

Nano Dimension is the pioneer and sole provider of AME 3D printers. The company’s signature system for high-performance electronic devices (HiPED®) is DragonFly. Nano Dimension also provides the software to prepare AME designs for printing, called FLIGHT. FLIGHT contains aspects of both 2D electronic CAD (ECAD) and 3D mechanical CAD (MCAD).

How DragonFly Works

DragonFly uses multi-material inkjet deposition to build electronic circuits layer by layer. Most projects employ AgCite™ ®– a breakthrough silver nanoparticle ink for conductive connectors and passive components as well as a dielectric polymer (acrylate) that provides insulation and structure. The metal and substrate are printed simultaneously -- the metal is cured by infrared light, and the polymer by UV. The precise balance of these two material processes in DragonFly creates structurally stable circuit boards, antennas, and complex geometric applications with electric performance comparable to devices with standard components.

Technology

What are the major differences of DragonFly AME output and traditional manufactured electronics?

Manufacturing Multiple Layers

Although a traditional printed circuit board can have more than one layer, it’s not truly a 3D design space. By contrast, in AME devices, connections can be made in any 3D direction.

Embedded Passive Components

Many passive components, such as resistors, capacitors, inductors, can be printed inside the HiPED and operate at much the same level or better than off-the-shelf components.

Points of Contact

Stephan Krause

VP Sales EMEA

Nano Dimension (Nasdaq, NNDM) is a provider of intelligent 3D-printers for electronics, ceramic and micro-polymer parts that are changing the way the world manufactures.