Understanding Flexible Hybrid Electronics: An In‑depth Exploration

Flexible Hybrid Electronics: an introduction 〰️➰ ➿

Traditional electronic devices are limited in their application due to their inflexibility and weight. In contrast, Flexible Hybrid Electronics break free from these limitations by prioritizing flexibility. This means that electronic devices have crucial features:

🟢 Flexibility and Conformability: electronic devices can now be malleable, bendable, and able to adapt to various forms

🟢 Lightweight: flexible substrates significantly reduces the overall device’s weight, making FHE ideal for weight-critical applications

🟢 Customization and Scalability: tailored designs and functionalities, possible to create bespoke solutions for specific applications

🟢 Cost-Efficiency: FHE manufacturing processes more economical, particularly for large-area applications

FHE utilizes dispensing and deposition techniques to craft electronic patterns on flexible substrates. These includes inkjet printing, screen printing, aerosol jet dispensing, gravure dispensing, and more, ensuring precise deposition of conductive and non-conductive inks for circuits, sensors, and functional components. 🔬

Ultra-Precise Dispensing technology is revolutionizing flexible hybrid electronics and other industries. With its ability to achieve microscopic precision, deposit multiple materials, and maintain high throughput, UPD is transforming electronics manufacturing. As we tap into its full potential, we can expect a future where electronic devices seamlessly integrate into our lives, delivering unmatched precision and functionality. 👌

Read more:

➡️ Understanding flexible hybrid electronics: An in‑depth exploration

Related Articles

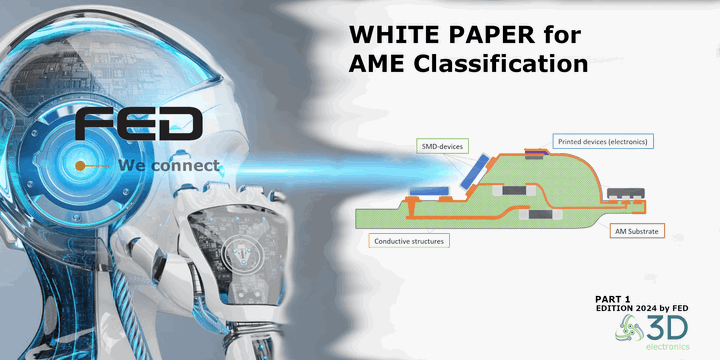

FED Working Group For 3D Electronics - New English White Paper Edition 2024

FED White Paper Edition 2024 - PART 1 - Introduction To 3D Electronics