Ultra-Thin Chips With Printed Interconnects On Flexible Foils

The research paper "Ultra-Thin Chips with Printed Interconnects on Flexible Foils" was authored by Sihang Ma, Yogeenth Kumaresan, Abhishek Singh Dahiya, and Ravinder Dahiya. Published in Advanced Electronic Materials in December 2021, this work showcases innovations in hybrid flexible electronics.

Research Objective

The study has overcome challenges in the integration of fragile UTCs with flexible foils for hybrid flexible electronic systems by using non-contact printing. Standard methods of integration mostly damage the UTCs, while this new route employs non-contact printing to provide robust interconnects with high electrical conductivity and mechanical stability.

XTPL Technology in Focus

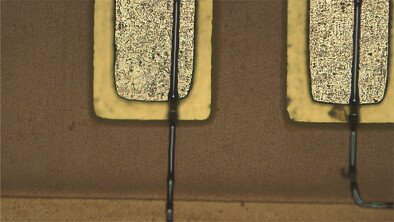

In this context, the core of the research is based on XTPL's high-precision extrusion printing technology, which enables reliable interconnects for ultra-thin chips on flexible substrates. The technology supports seamless integration using a conductive silver nano-paste (XTPL CL85) with resolutions as fine as 1 µm. This approach eliminates the mechanical stress and high-temperature requirements typical in traditional bonding methods, preserving chip integrity and performance.

Table of Contents

- Introduction: Challenges and opportunities in hybrid flexible electronics.

- Chip Thinning: Techniques for reducing chip thickness to 35 µm.

- Printing Interconnects: Details of XTPL's extrusion printing for robust bonding.

- Device Characterization: Evaluating electrical and mechanical performance.

- Conclusion: Key findings and future applications.

Highlights of Findings

Precise and Reliable Interconnects: XTPL enabled the direct deposition of high-viscosity silver paste, yielding low-resistance, highly conductive interconnects.

Minimal Performance Degradation: Even after the addition of printed interconnects, the UTCs still exhibited a high field-effect mobility of 630 cm²/Vs with minimal degradation due to the added resistances.

Mechanical Stability: The bonded UTCs exhibited good performance under bending conditions with a 40 mm radius, which provessuitable for flexible electronics.

Simplified Fabrication: This single-step additive process removes theneed for complicated traditional methods, significantly decreasingmanufacturing cost and complexity.

Related Articles

Enhancing Electrical High-frequency Performance By An Optimized Additive Manufacturing Strategy