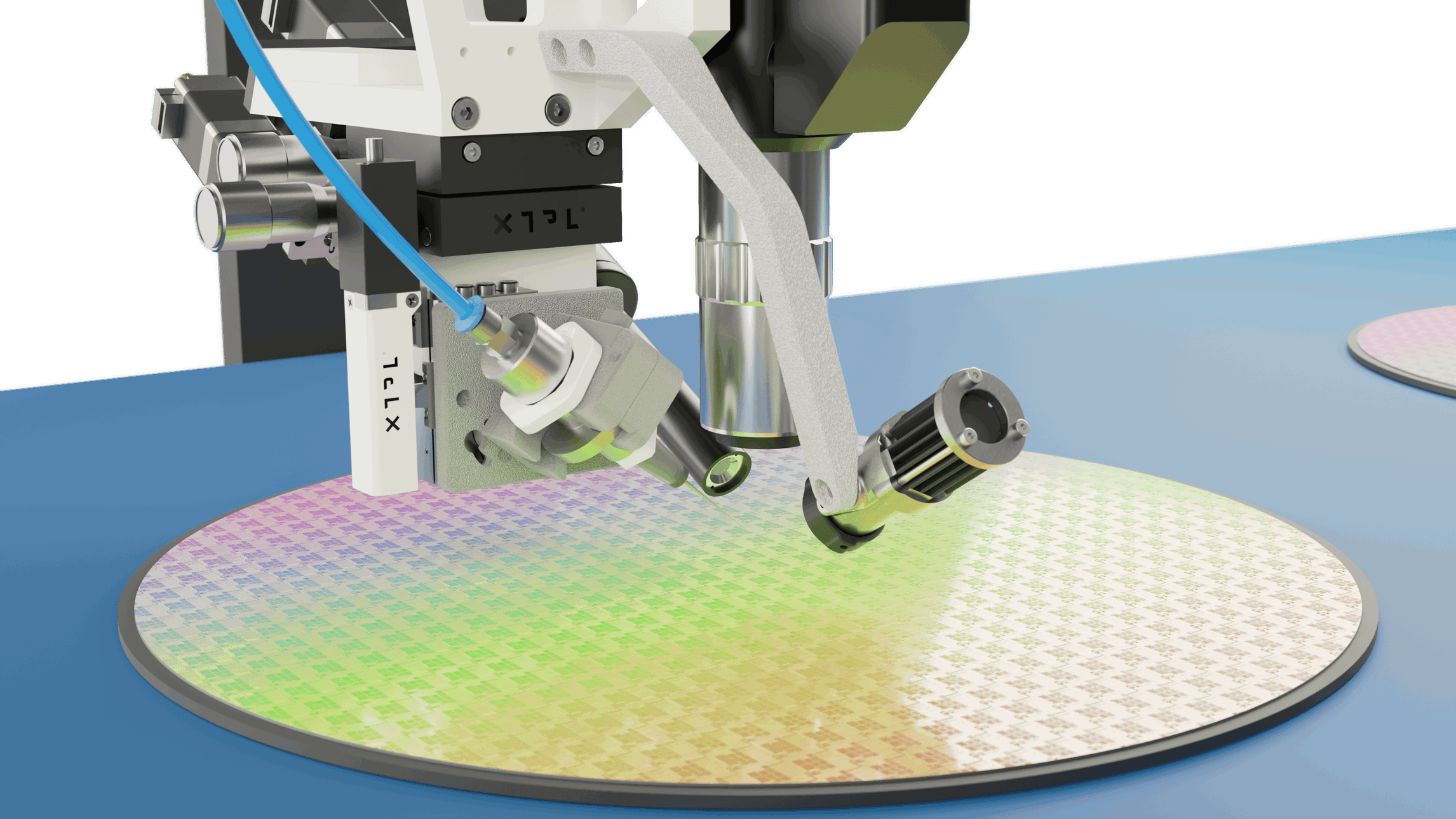

The Mastery Of UPD Technology In Nanomaterial Dispensing For Advanced Manufacturing

XTPL Ultra Precise Dispensing (UPD) technology is a system, standing for precision and innovation, that seamlessly integrates into both existing and prospective production lines. The UPD system, exemplifying ultra-high resolution printing, redefines precision in nanomaterial dispensing. Its key technological capabilities encompass:

• 2D, 3D conductive micro interconnections proficient in open defect repair methodologies applied to intricate technological substrates,

• ultra-precise circuit editing mitigating design flaws or intentional modifications via targeted dispensing directly on 2D/3D connections within the circuit.

Ultra-Precise Dispensing System proves its capabilities in the precise dispensing of nanomaterials through a range of applications across industries:

• customer electronic: UPD technology in advanced PCBs, also known as HDI (High Density Interconnector) PCBs, stands out for its superior wiring density per unit area compared to conventional PCBs. It features finer lines and spaces, smaller vias and capture pads, and a higher connection pad density.

• MEMS (Micro-Electro-Mechanical Systems): UPD technology assumes a pivotal role in the fabrication of microstructures with ultra-high resolution.

• MedTech: the UPD system initiates a paradigm shift in health technology by facilitating the fabrication of biosensors with unparalleled precision.

7 main benefits are standing behind UPD System efficiency:

• Precision and accuracy: the UPD system ensures unrivalled precision and accuracy in the dispensation of nanomaterials, culminating in the fabrication of highly precise conductive and nonconductive structures pivotal for advanced electronic components

• Versatility in material compatibility: UPD ensures compatibility with various conductive and nonconductive substances

• Customization and flexibility: tailored dispensing parameters and configurations offer flexibility, empowering manufacturers to customize the system to meet specific production requirements and diverse applications

• High throughput: enhances throughput, enabling increased manufacturing speed without compromising precision—a critical advantage in the dynamic realm of advanced manufacturing. The technology provides an appealing combination of high throughput and a resolution below 10 μm in diameter

• Scalability: the UPD system is inherently scalable to accommodate a spectrum of production scales, ranging from small batches to large-scale manufacturing.

• Reduced production downtime: the UPD system’s reliable and robust nature minimizes downtime, thereby contributing to heightened overall production efficiency and output

• Expert engineering support: The inclusion of top-notch engineering services guarantees that manufacturers receive expert guidance, support, and troubleshooting throughout the integration process

The emergence of UPD technology is revolutionizing precision printing across various industries, highlighting its capabilities and benefits. With its extremely accurate dispensing capabilities, UPD not only meets current manufacturing norms but also paves the way for future advancements in nanomaterial dispensing by combining precision and ingenuity. As industries evolve, UPD technology leads the way in reshaping advanced manufacturing with its unmatched precision and adaptability.

Read the whole article ➡️ The Mastery of UPD Technology in Nanomaterial Dispensing for Advanced Manufacturing

Related Articles

Functionalization Of Additively Manufactured Ceramic Components Via Thick-film Technologies

Nanomaterials In 3D Electronics Printing: Enabling Multi-Material Circuit Fabrication

Design And Performance Of Additively Manufactured In-Circuit Board Planar Capacitors