Driving Innovation In 3D Printed Electronics: An Interview With Hanno Platz Of FED Working Group

The sector of 3D printed electronics continues to evolve due to the development of additive manufacturing and an increased demand for functional, miniaturized components. At the center of such developments is the partnership between J.A.M.E.S a leading online 3D printed platform and Fachverband Elektronik-Design, known as FED. Hanno Platz, General Manager and Chairman of the FED Working Group provides some insight into how this collaboration could shape the future of electronic manufacturing.

A Collaboration Through Synergy

The partnership of J.A.M.E.S and FED brings the broad community of professionals, researchers, and innovators working on 3D printed electronics. Platz considers the importance of this collaboration, emphasizing how it strengthens connections between stakeholders and accelerates knowledge transfer. He states, " The platform provides a fantastic opportunity to quickly and easily bring together interested parties and suppliers. One major advantage is that it is neutral and international, which opens doors for cooperation with research institutes and fosters knowledge transfer. Additionally, it allows us to track the latest developments in the U.S., Japan, and other countries."

For FED, with presently more than 700 members, including companies, institutes, and individuals involved in professional electronics development and production, this aligns perfectly with its mission. FED has always emphasized education and training for PCB designers, who need access to new technologies most, according to Platz. The association has a responsibility to keep its membership up-to-date with the latest developments. This agreement is a win-win for all parties involved, especially for our members.

The Future of 3D-Printed Electronics

Platz said, "As additive manufacturing continues to evolve in robotics, medical technology, and aerospace, among many other industries, there is obviously immense potential on behalf of 3D printed electronics integration." The long-term drive for functional integration and miniaturization creates the need for these new capabilities, he notices. The spatial arrangement of electronics and the ability to easily print sensors on surfaces aligns well with products usually manufactured in Europe in quantities of 100 up to several thousand pieces.

The ability to adapt, with the rapid development of 3D electronic technologies, makes it essential for professionals to stay updated. Platz insists that it is a matter of keeping in step with developments in the technological field: "Developments in 3D electronics and additive manufacturing are happening at such a fast pace that we must stay on top of them."

Overcoming Challenges in 3D Design and Manufacturing

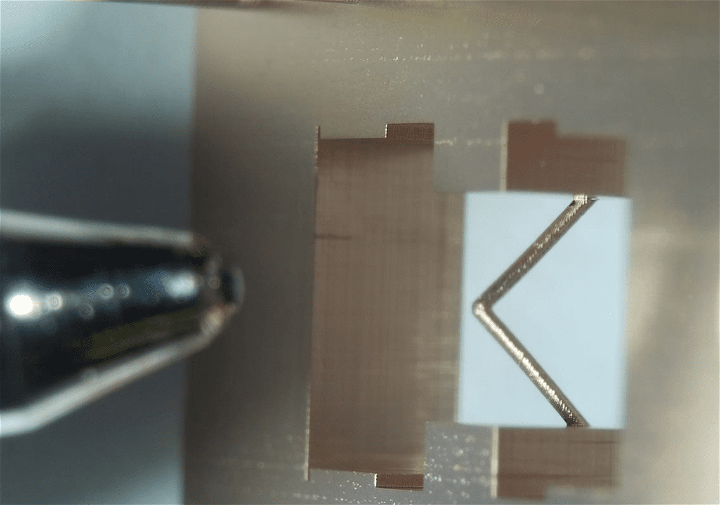

Although the prospects of 3D printed electronics are immense, there are challenges to be overcome. Platz points to the mindset shift required for engineers and developers as they transition from traditional design patterns to embrace 3D and additive solutions. Moreover, there is a need for better design tools. He explains, "The design tools needed for true 3D production aren't yet widely available. Data generated by eCAD systems aren't yet directly suitable for additive manufacturing processes."

Nevertheless, Platz remains optimistic, through initiatives such as the FED’s working group on 3D electronics, these challenges can be addressed. He highlights, "Their work on translation and updating a 26-page whitepaper on 3D electronics in English it to the current state of the field. The 2024 edition still needs to be translated into German. Additionally, he added "We are working on a list of required CAD features for each of the five classes. At the moment, EDA companies are still hesitant since customers are not yet purchasing the software. For discussions with the EDA companies, we need specific requirements."

Conclusion

As the field of 3D printed electronics continues to grow, the partnership between J.A.M.E.S and FED is set to play a pivotal role in its advancement. The collaboration between the two parties, along with knowledge sharing and innovation, will help overcome some of the challenges facing the industry and unlock its full potential. As Hanno Platz reflects on the future, it is clear that 3D printed electronics will be central to the next step of technological innovation.

FED White Paper Edition 2024

For anyone interested in reading the 2024 edition of the FED White Paper, check out the link below.

Related Articles

Ongoing Webinar Series: Additiv Im Südwesten