Exploring Electronics 3D Design and Printing

The design process of 3D printed electronics encompasses several stages, leveraging the integration of 3D digital designs, specialized 3D printing software and advanced additive manufacturing techniques. With the ability to print conductive and insulating structures from conductive and non-conductive material in the form of inks have expanded 3D printing to electrical applications.

Empowering Design Freedom

3D printing of complete electronic components offers greater design freedom as well as faster development times, enabling significantly more compact and cost-effective devices. Designing for 3D printing involves strategically integrating electronic component of circuits such as conductive connections, coils, capacitors, or antennas seamlessly within the design to ensure proper functionality and connectivity.

Streamlined 3d Design Process

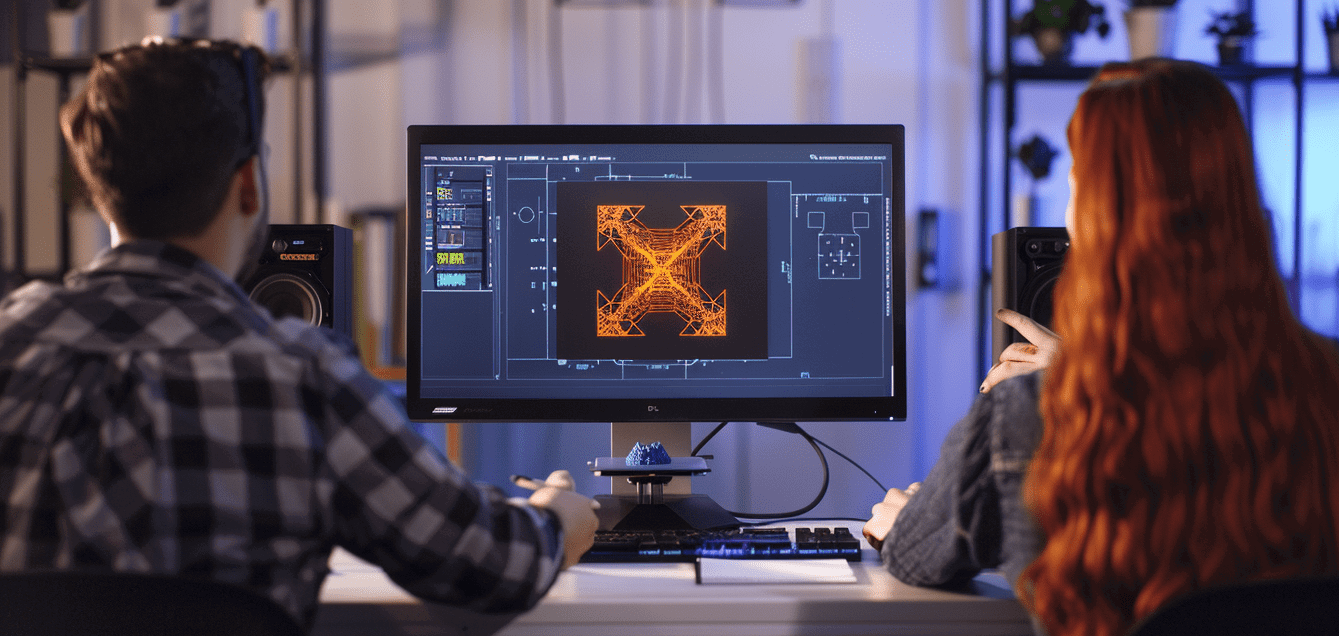

Our engineering team harness the power of specialized 3D printing software to design and bring additively manufactured electronics to life. At J.A.M.E.S, we use Dassault Systèmes’s CST Studio Suite for the design. This software supports 3D designs and is compatible with common ECAD standard formats, offering as well the possibility of simulation. For the mechanical design, the 3D CAD solution SOLIDWORKS is used.

Once the design is simulated and validated, the STL (stereolithogrpahy) files, which encapsulate the geometry of the design model for 3D printing, are prepared. These files are transferred to the 3D printer, which uses additive manufacturing techniques.

3D Model Preview - Brushless Motor Controller

Explore Our Design Collection

Dive into our AME Collection and Discover many 3D printing designs, complete with design tutorials and in-depth explanations of the targeted functionality and printer technology. With our intuitive 3D viewer tool, you can explore and validate 3D models with ease, and download STL files for 3D printing.

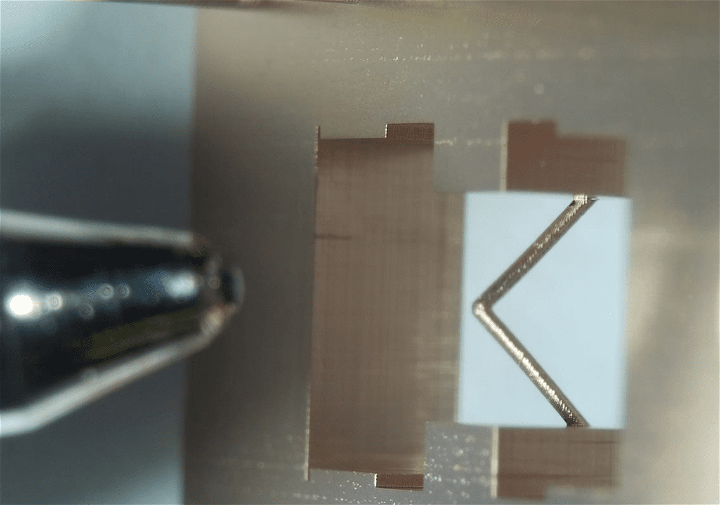

Axial Flux Motor

The realization of a motor functionality by using the third-dimensional freedom of an additively process shows the new possibility of creating an axial flux motor without using a mechanical coil winding procedure of copper wires.

Ame Chip Heatsink Capacitor

This design can be used for hardware IT-security issues, to protect a semiconductor chip against espionage, and reverse engineering by opening a chip housing. AME can provide bare chips with individually printed housing.

Join the Ame Community

Become part of a thriving community of innovators and experts. Share your designs, collaborate with industry professionals, and access educational resources and news - all for free!

Related Articles

FPM-Trinity - World Premiere At The INTERNEPCON JAPAN 2024 In Tokyo

Horizon Adds Metal Coatings To Its Portfolio Of 3D Microfabrication Technologies