Fabrication And Microwave Characterization Of 3D Printed Transmission Lines

This research paper "Fabrication and Microwave Characterization of 3D Printed Transmission Lines" was written by Paul I. Deffenbaugh, Thomas M. Weller, and Kenneth H. Church.

Overview

The paper discusses the application of 3D printing technology in the manufacturing of RF (Radio Frequency) and microwave circuits, particularly focused on transmission lines. The goal is to evaluate the feasibility of using 3D-printed transmission lines by comparing their performance to those produced through traditional manufacturing methods. The study examines various materials and designs, analyzing their performance at frequencies up to 10 GHz to provide valuable data for future 3D-printed RF designs.

Purpose

The paper aims to demonstrate the viability of 3D-printed transmission lines by conducting a comparative analysis with traditionally fabricated ones. It focuses on investigating the performance of 3D-printed materials and designs in RF and microwave circuits.

Motivation

3D printing offers several advantages, including rapid prototyping, increased design flexibility, and the capability to create complex structures that are challenging to achieve with conventional fabrication methods. This study aims to assess the performance of 3D-printed transmission lines, demonstrating their potential use in RF and microwave applications.

Methodology

The researchers employed two 3D printing techniques: stereolithography (SL) and fused deposition modeling (FDM), to fabricate the transmission lines. Key parameters such as characteristic impedance, effective dielectric constant, dielectric loss, and conductor loss were modeled and measured. The materials used for the study include ProtoTherm resin, ABS thermoplastic, and DuPont CB028 conductive paste.

Key Concepts

- 3D Printing in RF/Microwave Circuits: 3D printing enables rapid prototyping and manufacturing of RF/microwave components with complex geometries, offering advantages in design flexibility and iteration speed.

- Transmission Lines: Structures that carry RF/microwave signals from one point to another, whose performance depends on their physical and electrical properties.

Materials and Methods

- Stereolithography (SL): Offers high resolution and smooth surfaces but involves materials with higher losses at microwave frequencies

- Fused Deposition Modeling (FDM): Employs materials with lower microwave losses, though it produces lower print resolution and rougher surfaces.

- DuPont CB028 Conductive Paste: Applied for fabricating conductive paths, with an specific focus on its DC and RF resistivity characteristics.

Measurement Techniques

- Characteristic Impedance: Indicates the inherent impedance of a transmission line, affecting signal integrity.

- Effective Dielectric Constant: Measures how much a material slows down electromagnetic waves passing through it.

- Dielectric and Conductor Losses: Losses due to the material properties of the dielectric and conductor in the transmission line.

Modeling and Analysis

- Use of software tools like Ansys HFSS for simulating transmission line performance and extracting parameters from measured data.

Table of Contents

- Abstract

- Index Terms

- I. Introduction

- Overview of 3D printing in RF/microwave components

- Advantages and challenges

- Objectives of the study

- II. Fabrication

- Fabrication methods: SL and FDM

- Material properties and sample preparation

- Full 3D printing process

- III. Modeling

- Simulation techniques and models used

- Parameter extraction and analysis methods

- IV. Measurement

- Measurement setup and tools

- Data analysis and interpretation

- V. Conclusion

- Summary of findings

- Future directions and recommendations

- References

- Cited works and related literature

Related Articles

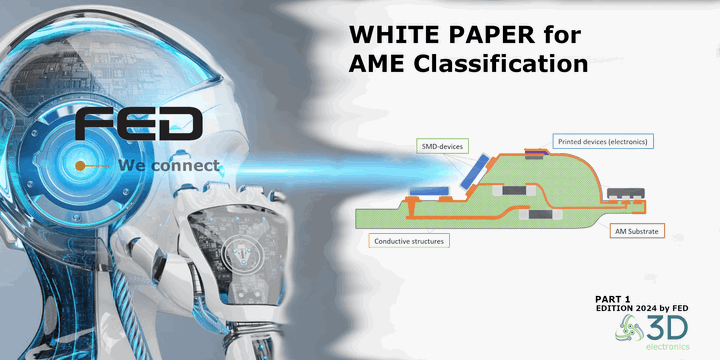

FED White Paper Edition 2024 - PART 3 - AME Class 3 And Class 4

Nanotechnology In HealthTech – Biofunctional Coatings For Implantable Devices

FED White Paper Edition 2024 - PART 1 - Introduction To 3D Electronics