Additive Manufacturing Of Interposers With Curved Vias For Microelectronics Packaging

This research was written by Tobias A. Schaedler, Kayleigh A. Porter, Alex C. Yu, Souren Soukiazian, Trevor Sasse, Erin S. Wernick, Phuong P. Bui, Jacob M. Hundley, Mark R. O’Masta. Explores the additive micro-manufacturing of ceramic interposers with metallized vias for advanced microelectronics packaging. Using digital light processing, the authors successfully fabricated interposers with ultra-fine vias, demonstrating their potential for high-density electronic integration. The study introduces novel designs, including curved and fan-out interposers, which enable complex via routing that is not achievable through conventional methods. These advancements pave the way for innovative approaches in microelectronic system development.

Affiliation: HRL Laboratories, LLC, 3011 Malibu Canyon Road, Malibu, CA 90265, USA

Abstract

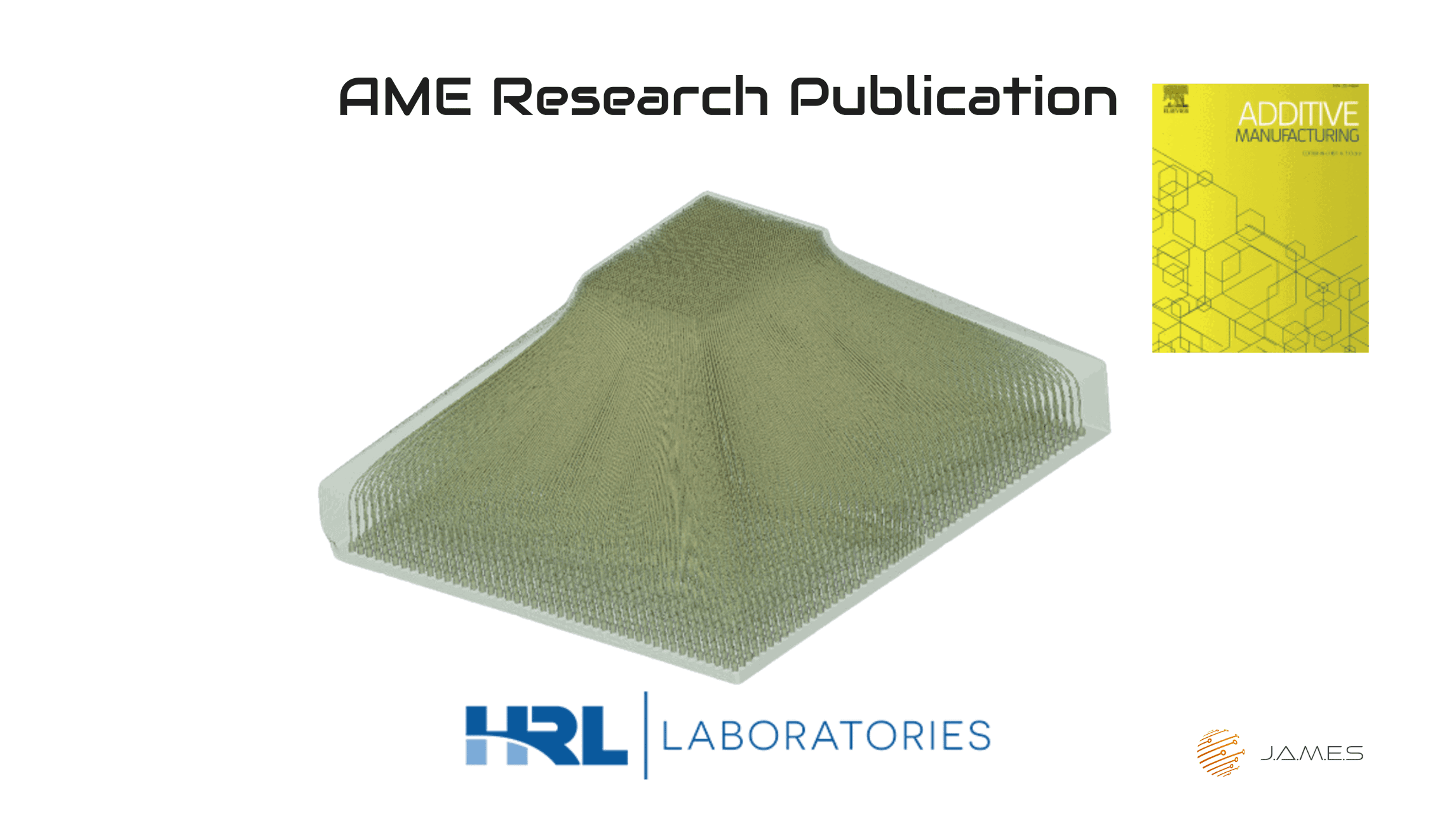

Advances in digital light processing now enable additive micro-manufacturing of parts on the centimeter scale, with features on the order of 10 μm. In this study, ceramic interposers were printed containing arrays of vias (holes), with diameters and pitches as small as 9 μm and 18 μm, respectively. The vias were subsequently metallized by melt infiltration to provide electric pathways. This technology enables unprecedented via routing, including curved and angled vias, offering new packaging options for the 3D integration of microelectronic subsystems. Two different interposer designs were demonstrated: 1) a curved interposer intended to connect a curved infrared detector with a planar read-out integrated circuit (ROIC); and 2) a fan-out interposer that spreads the pitch of an array of vias from 60 μm to 220 μm. These interposers require thousands of curved and angled vias, respectively, that cannot be realized using conventional microelectronics processing approaches.

Highlights

- Ceramic interposers with curved vias at pitches as small as 18 µm were 3D printed.

- Curved vias with aspect ratios of 150:1 were metallized.

- An interposer to connect a curved infrared detector was fabricated

- A fan-out interposer that spreads the pitch of an array of vias was fabricated

Key Findings

-

Successfully 3D printed ceramic interposers with curved vias at 18 μm pitch.

-

Achieved metallization of curved vias with an aspect ratio of 150:1.

-

Developed an interposer connecting a curved infrared detector to a planar ROIC.

-

Fabricated a fan-out interposer for efficient via pitch expansion.

This research demonstrates the transformative potential of additive manufacturing for microelectronic packaging, enabling novel interposer geometries and enhanced system performance.

Related Articles

Durability Investigations Of 3D Printed Electronics Towards Aeronautic-inspired Environmental Loads