Printing Biomedical Sensors With Ag/AgCl Ink

A recap of our webinar on biomedical sensors printed with silver silver-chloride ink using NOVA.

Introduction

Estimated reading time: 3 minutes

In this webinar, the spotlight was on printing biomedical sensors using NOVA technology, a landmark in the evolution of printed electronics. We aslo highlighted Creative Materials' 124-36 Ag/AgCl (silver silver-chloride) ink, which was perfect for the application we demonstrated.

Precision Materials Dispensing

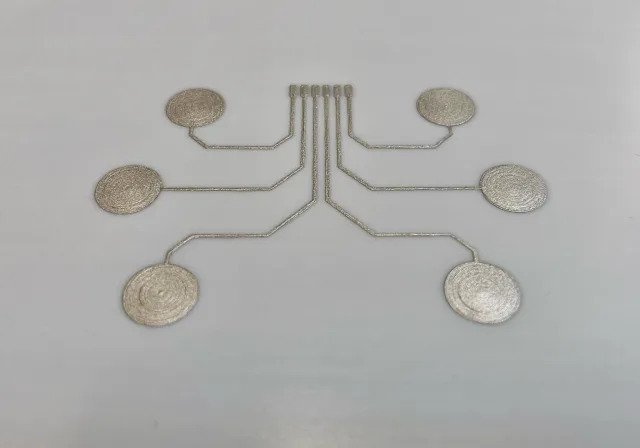

The webinar focused primarily on the precision and adaptability of NOVA in printing biomedical sensors. With the use of advanced materials and sophisticated printing techniques, made easier with products like NOVA and Creative Materials inks, you’re able to create sensors that are both highly functional and biocompatible.

Webinar Highlights

Printing techniques explored: We demonstrated various methods like syringe dispensing and screen printing, emphasizing their relevance in biomedical applications.

Material compatibility: The webinar highlighted the compatibility of NOVA with a range of materials, including innovative silver/silver-chloride inks.

Flexibility: Customization became a key theme, with discussions in the live chat of the webinar on tailoring sensor designs to specific biomedical needs and the flexibility of materials on different substrates.

Interested in exploring NOVA's capabilities for your biomedical projects? Get in touch with our experts for a personalized demo or more information.

Audience Q&a Insights

Ink selection: One question inquired on the difference between pure silver inks and silver/silver-chloride inks. Our experts explained that while pure silver offers higher conductivity, silver/silver-chloride inks provide greater biocompatibility, crucial for sensors in direct contact with skin.

Printing on flexible materials: A question arose about NOVA's ability to print on flexible substrates and we clarified that NOVA's precision and pressure feedback dispensing make it ideal for such applications, above and beyond the capability of the V-One.

Ink preparation and handling: Questions about ink preparation underscored the importance of proper material handling for optimal printing results. Many helpful tools and techniques were highlighted, including but not limited to:

- A planetary mixer to help blend materials to ensure a complete mix and consistent flow.

- Deflection testing to identify whether there’s air in the dispenser, which is further helped by the pressure feedback from NOVA’s Smart Dispenser.

- Consultation with experts (like Creative Materials) for recommendations when you’re looking to create custom mixed materials for your application.

Practical Demonstration

A significant portion of the webinar was dedicated to a live demonstration, showcasing the printing of a biomedical sensor using NOVA. This hands-on display not only highlighted the machine’s capabilities but also addressed practical considerations like setup time and material preparation.

Want to watch the demo but didn’t make it to the webinar? We’ve got you covered with a copy of the recording:

Applications and Future of Printed Electronics in a Biomedical Setting

We discussed the wide range of applications for printed biomedical sensors, from EKG and EEG sensors to more novel uses in drug delivery systems and comfortable, wearable health monitors. The session also touched upon future trends and potential advancements in this rapidly evolving field.

Special thanks to everyone who participated in the chat. There were many questions about the capabilities of NOVA and Creative Materials inks. The most common themes were the importance of precision in dispensing, versatility in materials, and customization for creating advanced medical devices.

Do you want to see how our customers are using our materials dispensing systems to innovate the electronics of the future? Click here.

For pricing or to speak with a member of our applications team, please click here to book a meeting.

Comments

Related Articles

Harnessing Digital Printing And Functional Materials For Breakthroughs In Printed Electronics

FED Talks: Online Webinar To Agile Electronics