How To Scale AM For Demanding Applications

Scaling the additive manufacturing (AM) process to meet the needs of demanding sectors requires a strategic approach. From planning and prototyping to pulling together a skilled, cross-functional team, this guide explores how you can increase the volume of AM without compromising the quality of your end product—even in the most challenging of industries.

Here's how to scale AM.

A Strategic Foundation

A scaling strategy helps you integrate AM into your existing workflows. It ensures every decision aligns with your goals—whether that be increased efficiency or more robust risk management.

Before you can build a scaling roadmap, however, you need clarity:

- What are your pain points? Where are the bottlenecks in your existing manufacturing processes?

- What are your non-negotiables—what must your industrial 3D printing solution deliver to be considered a success?

- What other systems, software, and technologies does your AM solution need to integrate with?

- What kinds of workforce training will you need before your AM solution goes live to bridge skills gaps?

- Do you have contingency plans in place? What happens if something goes wrong during your scaling initiative? What if there are unexpected delays?

- What does success look like? What are the key metrics or performance benchmarks you can track?

Your answers to these questions will form the foundation of your scaling strategy. With a clear understanding of your direction, you can begin fleshing out your plan.

Step 1: Build a Dedicated Team

Scaling AM requires expertise from across your organisation. Put together a diverse team of stakeholders to take ownership of AM-related developments. This might include:

- Activities related to initial setup and investment, like securing funding for 3D printers

- Skill building for engineers and designers

- Change management that builds excitement and secures buy-in from other departments

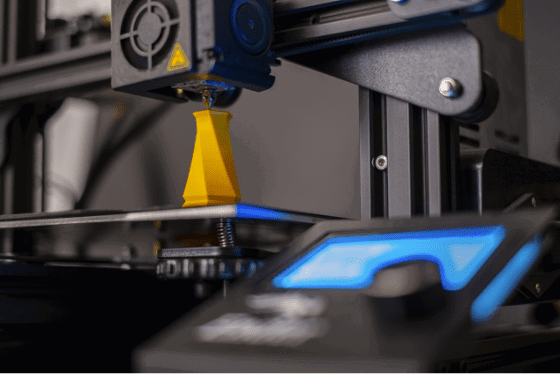

Step 2: Start With Prototyping

You've got a team, and they've kick-started your AM initiative. They've invested in the right technology, and now, it's up to your engineering and product development team to take over. Rather than diving head first into your products' most critical components, it's a wise idea to first validate your AM capabilities.

To do this, you might start with rapid prototyping. This iterative process allows you to test and validate the design before committing to production at scale. You might also collaborate with engineering departments to determine which parts are most suitable for AM.

The goal during this phase is to refine your workflows and build confidence in your new AM capabilities.

Step 3: Experiment and Refine

If your early prototyping shows promise, you can begin to expand your use of AM into more complex applications.

Now's the time to experiment with new materials. Consider combining materials to reinforce parts and build strength. You can also tweak and refine your processes, integrating quality assurance through every stage of your workflow.

This stage of trial and error is all about ironing out the kinks. That way, when you scale operations, you reduce the risk of time- and resource-intensive errors.

Step 4: Assess Your ROI

You're almost ready to scale. Before you take the next step, calculate the return on investment (ROI) of your AM initiatives using insights and data gathered from your prototypes and experiments.

Consider ways in which you could increase your ROI, too. For example, you might invest in more advanced 3D printing technology, such as metal or large-format 3D printers. Or, you could leverage cloud-connected 3D printers to enable just-in-time (JIT) manufacturing. This cuts inventory costs and speeds up delivery. It's also worth establishing a centralised hub for AM knowledge and processes.

Step 5: Scale Your AM

With all the groundwork laid, you know how to scale 3D printing. You can officially begin utilising your AM solution to its full capacity.

Remember, it's not a one-and-done process. Continually revisit your systems and refine and optimise them. Invest in new technology and train your team with up-to-date information.

Related Articles

Impressions From Formnext 2024: The Hub For Additive Manufacturing