What’s Next For Large-Scale 3D Printing?

3D printing represents an exciting shift in how products are designed and created. It allows for unparalleled customization, greater material efficiency, and the ability to manufacture complex geometries. However, one limitation has curbed its potential: scale.

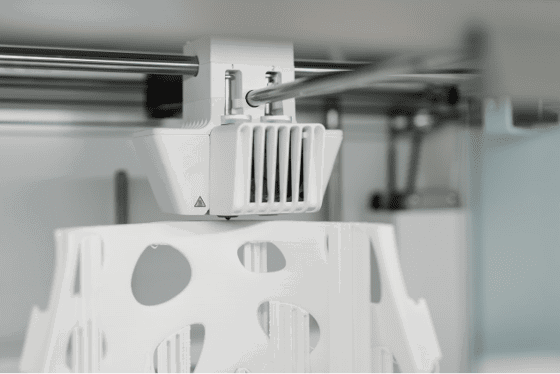

Traditional 3D printers are constrained by build volume. This means producing large, functional objects in one seamless piece is impossible. Manufacturers are instead forced to create smaller parts and then assemble them—a time-consuming and, therefore, costly undertaking.

But, all this changes with large-scale 3D printing.

What Is Large-Scale 3D Printing?

Large-scale 3D printing is an additive manufacturing (AM) innovation that enables massive, single-piece structures to be produced. Large-scale 3D printers are often 1 metre or more in dimension, eliminating the need for assembling smaller parts while delivering greater strength and structural integrity. The largest object 3D printed—a boat called 3Dirigo—was created by the University of Maine Advanced Structures and Composites Center and measures 2.06 m³.

Large-scale 3D printers offer industrial-grade reliability. They are built for heavy-duty applications, which means they feature robust frames, powerful motors, accurate extruders, and intelligent control systems to secure precision during prolonged operations. The heated print bed is critical to achieving this, too. This element holds a consistent temperature throughout the entire printing process, ensuring even the most extensive or complex prints are properly adhered to and stable.

The Benefits of Large-Scale 3D Printing

Large-scale 3D printing ensures efficient production. Here's how:

- Joins and seams are weak points in 3D-printed parts. Single-piece construction reduces assembly needs, which makes for stronger parts.

- Manufacturers transitioning from traditional processes to large-scale 3D printing will experience significant time savings. Mould creation and assembly take time, but 3D printing eliminates these steps and accelerates the production cycle.

- 3D printing on a larger scale cuts material waste and eliminates tooling costs. This makes it a viable solution for small-scale and mass production.

What's Next? Application of Large-Scale 3D Printing

Large-scale 3D printing supports a diverse range of materials. Organisations across industries can leverage the technology to produce lightweight, custom solutions.

Construction

Architectural freedom reaches new heights with 3D-printed homes, bridges, and even emergency shelters. Large-scale 3D printing speeds up construction and minimises resource use.

Aerospace

Aircraft manufacturers leverage the technology to craft high-strength composite parts that reduce weight and improve performance. The ability to design large, seamless components boosts safety and delivers unmatched fuel efficiency.

Maritime

In shipbuilding, 3D printing streamlines production with custom, on-demand parts. This capability is a game-changer for at-sea maintenance.

Trends Shaping the Future of Large-Scale 3D Printing

What's on the horizon for large-scale 3D printing? Here are some trends shaping the future:

- Printing powered by artificial intelligence (AI)

- Advancements in composite materials

- Increase in service bureaus for greater accessibility

- More interest in corporate sustainability

As promising as it is, large-scale 3D printing faces challenges. Equipment costs are high, and materials are not yet standardised. What's more, organisations operating in industries required to meet strict regulatory compliance must ensure large-scale 3D printing adheres to applicable guidelines.

Bigger and Better

For businesses seeking to stay ahead, large-scale 3D printing is redefining what's possible. Stronger, single-piece components will enable all-new levels of efficiency, sustainability, creativity, and innovation. Watch this space.

Related Articles

The Basics Of Horizons Proprietary Coatings For Plastic Micro AM Parts

Pioneering Advancements In Precision Agriculture: The DJI Agras T50