Innovative Breakthroughs In 3D Printed Electronics: Insights From MIT And Beyond

Improvements in 3D printing technologies are giving the world of electronic manufacturing a sea change. Tapping into the power of 3D printing to manufacture high-performance electromagnets and solenoids, MIT research has opened an innovative paradigm in electronic device manufacturing. This throws open fabrication of complicated magnetic components with ease, hence beckoning major breakthroughs in a large number of industries.

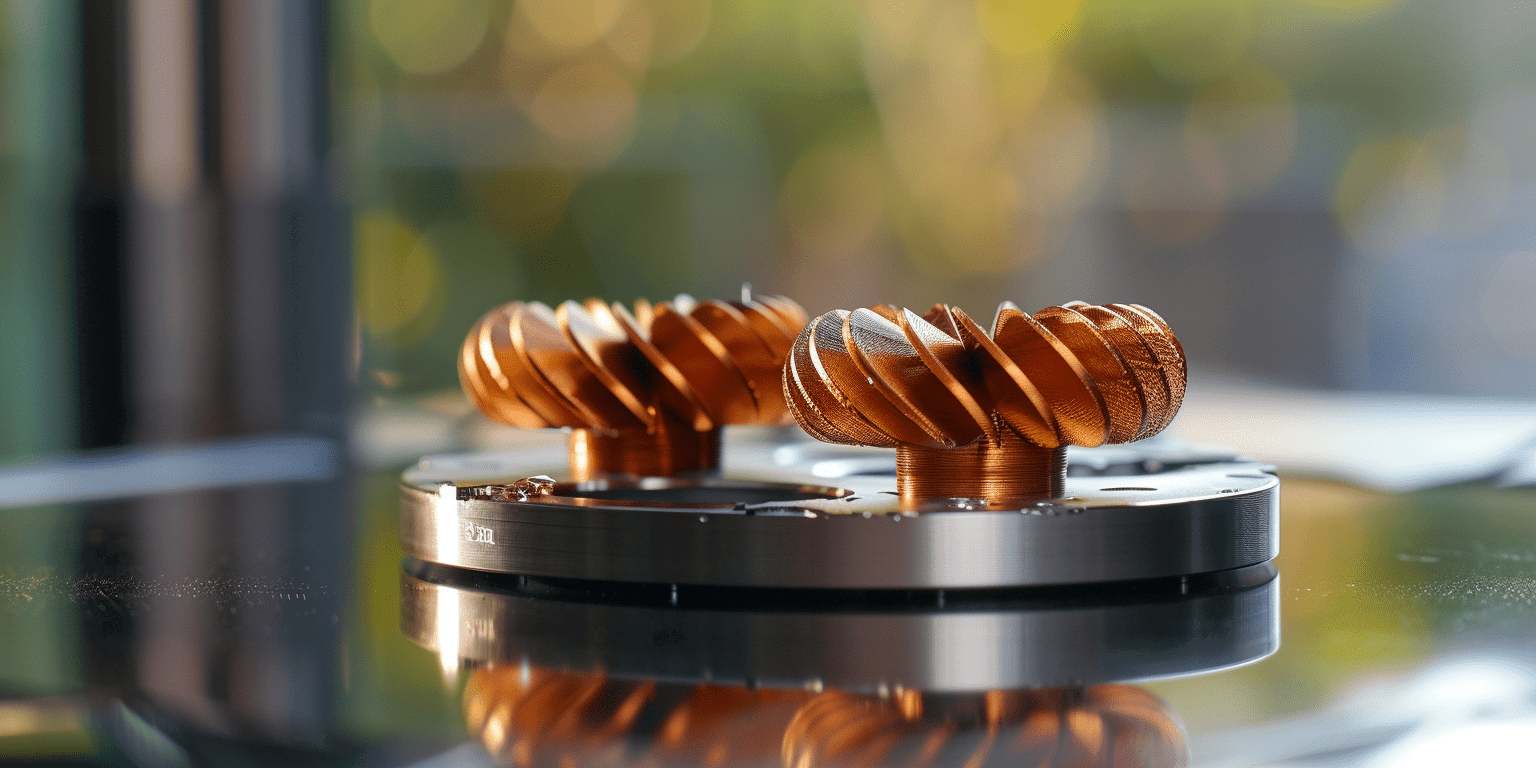

MIT's Breakthrough in 3D Printed Electromagnets

Researchers at MIT have developed a new 3D printing process to fabricate highly accurate electromagnets and solenoids. This involves layered deposition of magnetic materials, enabling the creation of complex designs previously impossible with traditional manufacturing. The printed components show improved performance that broadens their use in applications such as medical devices, robotics, and consumer electronics.

The possibility of customizing the shape and properties of magnetic components gives way to new directions in innovation. For example, medical devices can now be miniaturized and become more powerful, while the robotic systems can integrate more precise and stronger actuators. This personalization is a radical step forward that allows designers and engineers a flexibility that was previously unimaginable.

The Role of Additively Manufactured Electronics

One of the drivers is the rapid growth of 3D printing technologies, which would, in turn, set a base for the space of AME focused on fabricating electronic components through additive processes. Among the critical advantages of this approach over conventional methods of manufacturing include:

Design Flexibility: AME allows for the creation of complex geometries and integrated structures, which cannot be created or are challenging to create using conventional methods. This is particularly essential for the development of advanced electronic devices with different form factors and functionalities.

Rapid Prototyping: With 3D printing, prototyping can be done at an exponential speed. Hence, the iteration cycles for product development can be accelerated. This pace is needed for innovation and is critical for researchers and engineers to prototype, try, and optimize their designs quickly.

Sustainability: Because it creates products a layer at a time, AME generates very little waste material and uses less energy, making it much more environmentally friendly than traditional manufacturing processes.

Applications and Future Prospects

Conclusion

The benefits to Additively Manufactured Electronics are best explained using the examples from MIT which would make 3D printed electromagnets viable for making actual parts in a variety of industries. In medicine, magnets can be tailor-made to create powerful MRI machines or help challenge the effectiveness of drugs. AME: Also, advanced compact consumer electronics that provide improved performance along with lower size and weight.

Local fabrication of such complex magnetic components would also be a game changer for supply chains — perhaps even more so than the sparking decentralization we saw in manufacturing plants over centralized hubs decades ago. Developing more robust, flexible manufacturing systems would allow Department of Defense organizations to respond quickly as the market atmosphere changes.

Breakthroughs in 3D-Printed High-Performance Electromagnets, Solenoids at MIT Highlight Additive Manufacturing's Transformative Capabilities AME increasingly forms the backbone for innovation in every industry. Learning to craft these advances therefore gets us one step closer towards the ingress of faster, custom-build and eco-friendly electronic merchandise if designed properly.

It is possible to make further references to the original article from MIT to add more dimensions of their research at MIT and the future of 3D printed electronics.

For more detailed information on MIT's research and the potential of 3D printed electronics, you can refer to the original article from MIT here.

Related Articles