The Impact Of 3D Printing On Wearables And Design

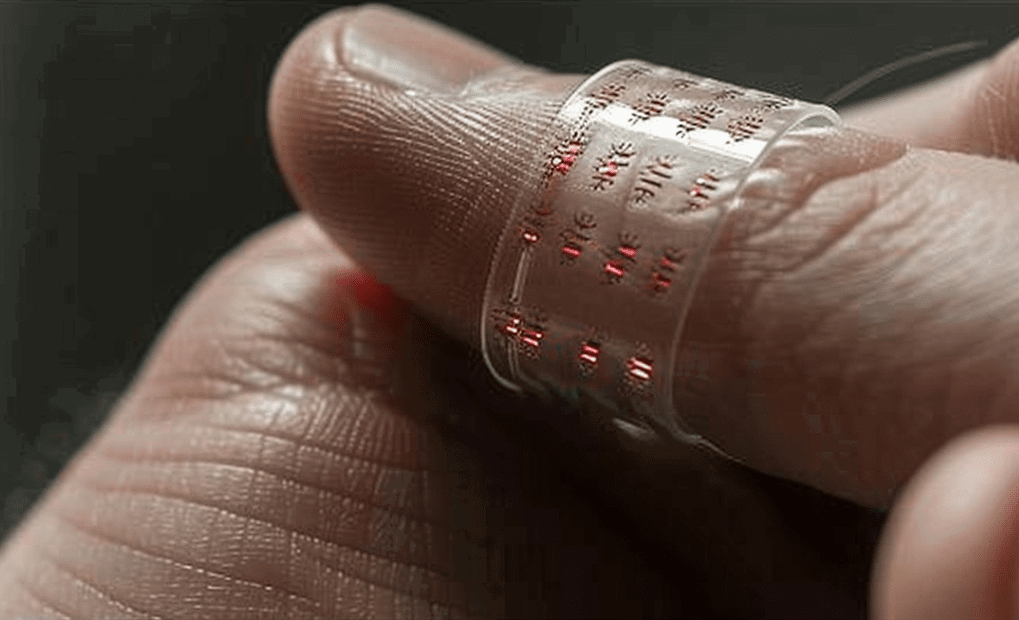

Wearable technology has changed the way we look at 3D printing. The field of healthcare benefits from customized solutions such as 3D-printed prosthetics and orthotics that enhance patient comfort and mobility.

3D printing is slowly but surely spreading into the field of fashion as a means for new, innovative designs and sustainable production methods that generate little to no waste. 3D printed sports equipment also improves athletic performance thanks to a custom fit and optimized design, the same as with any other sport-specific gear. These advances highlight the transformative role 3D printing is playing in wearable technology, catalyzing innovation and redefining user experience from different spheres.

Real-Life Examples

Prosthetics: Using 3D printing to create custom solutions for amputees. A company called Open Bionics is one of the leaders in this space, with affordable bionic arms for children and adults that can be fully customized. Twig Prosthetics Improve Mobility and Quality of Life

Footwear: Adidas and New Balance 3D-print shoes. Adidas Futurecraft 4D sneakers with Digital Light Synthesis midsoles for best support, and comfort. Structures and designs that simply can not be made with traditional manufacturing techniques.

Eyewear: Companies such as Fitz Frames and GlassesUSA make use of 3D printing for eyeglasses. To keep them snug and stylish each time, these glasses are personalized based on everyone`s facial features. Fitz Frames, for example, uses an app to scan the user's face and produce perfectly sized frames.

Popular Sectors

Healthcare: In healthcare, selective laser sintering is used in making custom prosthetic devices, orthotics, and dental appliances from the digital models of individualized patient anatomy. Rapid prototyping and exact customization 3D printing enables comfortable individual treatment, saving money

Fashion: 3D printing is used in fashion by designers such as Iris van Herpen and Julia Daviy to design out-of-the-box clothings, accessories. This technology allows us to develop complex products and sustainable manufacturing with very low waste.

Sports: We will also see customized sports equipment such as 3D-printed cleats or football helmets for NFL players. Under Armour is a company that produces advanced materials like 3D-printed shoe soles or protective gear for superior performance and wear comfort.

Current Trends

Sustainability: It helped in minimizing waste, reducing excess and leftover materials (which would normally result) from the process. Enter biodegradable and recyclable materials companies are investigating as a way to prepare the automobile for the green initiative.

Customization: Product Design = Prototype Wearables Getting Smaller, More Personalized 3D printing makes it easier to have customized solutions, from medical devices to fashion accessories.

Speed and Efficiency: Time-Saving Capabilities - processing plants can print specifics in hours, not days due to new 3D printer technology. Quick prototyping speeds the development process and moves products toward quicker release.

3D printing technology has fundamentally reshaped the wearables sector, allowing for a new generation of bespoke sustainable solutions in healthcare, fashion, and sport. The Next Gen Body Intelligence Experience Not only these current top WIM devices revolve around body awareness applications like mindful movement, but there are intrinsic properties of biofeedback from monitoring the human vehicle that will be able to hack you into a Next Gen experience flowing state. Let me paint my vision in terms of everyday activities as this technology continues to evolve.

Related Articles