Populating With IR-Heater

Dispensing of Solder Paste and curing under an Infrared Heater is one of the easiest ways to populate your AME-Board.

Recommendation:

- Let the Solder Profil run once without the Board to ensure sintering

- If shortscircuits or opencircuits are visiable add flux and run the solder profil once again

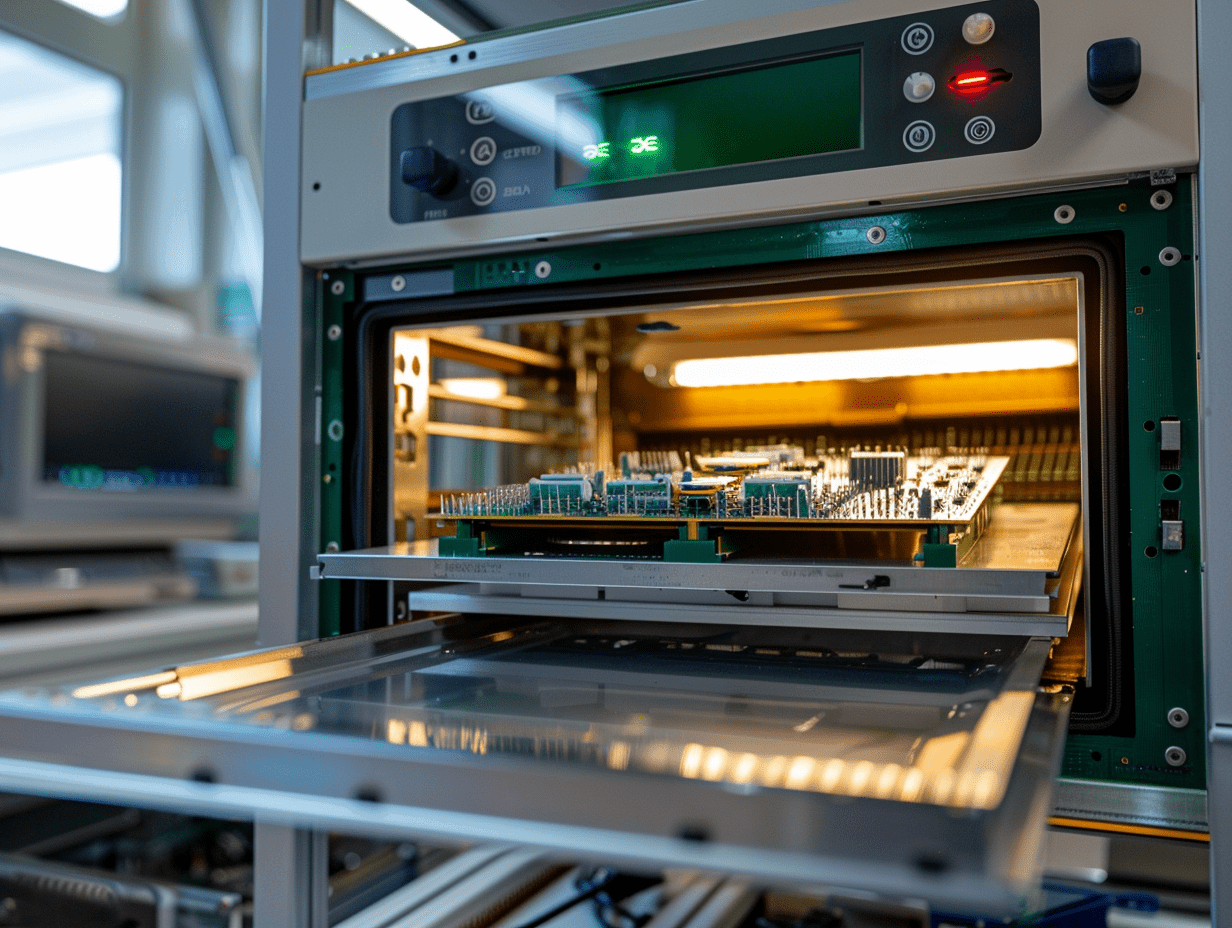

Soldering Equipment

At J.A.M.E.S we are using an Infrared IC-Heater Model T962 for soldering our applications in one heating profile process. It is possible to create an individual heating profile to achieve proper results for 3D-printed AME structures produced by the DragonFly IV multijet printer.

To do this, choose wave7* or wave8* to program the temperature vs. time and store following profile.

For more details, refer to the attached manual of the T-962 Infrared heater.

Solder Paste

Any low-temperature solder paste would be suitable.

Our choice is a solder paste Sn42/Bi57/Ag1.

Solder Profile

To achieve a good connection, use the following soldering profile:

- Preheat zone: heat to 153°C in 150 seconds

- Reflow zone: 60 seconds at a peak temperature of 153°C

- Cooling zone: 120 seconds

Alternatively, the solder paste manufacturer profile can be used.

Step 1: Cleaning the Pads

In order to clean the pads and remove oxidized silver use a simple rubber eraser. Since the silver pads of the AMEs manufactured on the NNDM DragonFly IV printer might be very sensitive, it is important to proceed with caution. As an alternative to the rubber eraser, a fiberglass pen might be used.