HYMAG'In - Advanced Magnetic Materials For Next-gen Electronics

Hymag'In, a France company, has become a pioneer in manufacturing magnetic iron oxide nanopowders important to many future technologies: telecommunications, electronics, and aeronautics. The company produces these advanced materials locally in Europe. Their materials are destined for future applications regarding electric vehicles, 5G networks, and embedded systems, which need stringent specifications for magnetic properties to function optimally.

The most important development of Hymag'In is soft magnetic micro- and nanopowders. Soft magnetic powders are used for the preparation of thin coatings and 3D-shaped composites. These newly developed materials are crucial in reducing the weight and size of electronic devices, along with energy consumption, while improving such device performance. Moreover, the environmentally friendly manufacturing process and the use of secondary raw materials in its production depict a way toward minimizing environmental impact by Hymag'In.

The R&D team at Hymag'In works in collaboration with customers to co-develop their own magnetic nanopowders, from prototypes to mass production. Besides custom development and manufacturing, Hymag'In allows customers to reduce time-to-market while delegating production risks.

FILAMAG: Magnetic Absorbing Filaments for Additive Manufacturing

FILAMAG is a product of Hymag'In, magnetic absorbing filaments designed for 3D printing. These filaments are made from ferrite materials, and tailored for industries like aerospace, defense, automotive, and telecommunications. Ferrites are critical for electronic systems, especially those needing electromagnetic compatibility. FILAMAG filaments offer effective solutions to the issues of miniaturization, weight reduction, and energy efficiency while preserving the required magnetic characteristics.

What sets FILAMAG apart is its ability to integrate ferrite powders into flexible or rigid polymer matrices, making it ideal for 3D printing electromagnetic absorbers and casings. These materials can absorb electromagnetic waves, reducing interference and improving device performance. For example, a lightweight 3D-printed composite casing made by using FILAMAG filament has been used instead of steel metal covers, which can stop cavity resonance at a much lower weight.

One such versatility with FILAMAG enables various geometries to be adopted, such as micro-pyramids, honeycombs, or personalized shapes, that enable precise 3D printing for each application. In simpler words, it serves as a strong tool for broadband absorber design, along with tailored electromagnetic shielding solutions through many industries.

FILAMAG also contributes to the possibility of significantly improving the performance-to-weight ratio for their components on the side of manufacturers. These materials have managed to make the improvement in performance up to 12 times compared with conventional ferrite-based components, and that is quite important in the field of radar studies, wireless communication, and antenna design.

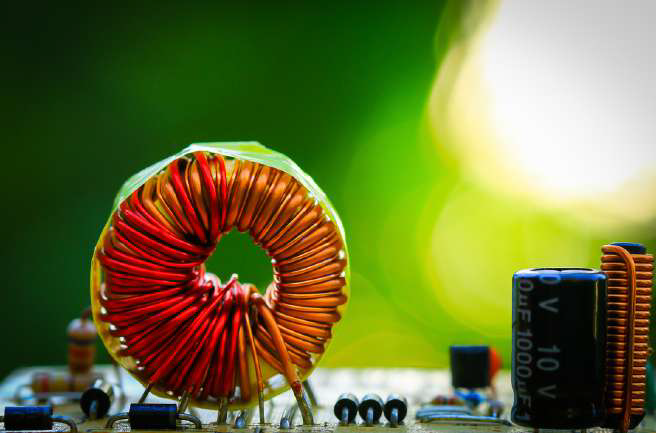

Ferrites in Electronics Devices

Ferrites are widely used in electronic systems as essential magnetic materials for passive components and solutions for electromagnetic compatibility (EMC). They play a crucial role in miniaturizing devices, reducing weight and energy consumption, and ensuring efficient electromagnetic shielding.

Electromagnetic absorbers

Passive components

Get in Touch

For more insights into additively manufactured electronics, contact J.A.M.E.S, where our experts can support you in turning your AME story into a success. From deep technical insights to market overviews on AME processes, we provide the knowledge you need.

If you're interested in connecting with Hymag'In, feel free to reach out for collaboration opportunities.

HYMAG'IN, A Beautiful Story

Founded by Camille CROUZET and Philippe LE BOUTEILLER, the start-up is developing the production of 3D printable magnetic materials. These products are used to protect electronic systems against interference.