From Concept To Qualified Product

Using additive manufacturing electronics (AME) has huge potential for new products and applications. By blending traditional 3D printing methods with electronics, AME creates exciting opportunities for innovation and design. This approach is set to change industries by allowing the development of complex and highly integrated electronic components.

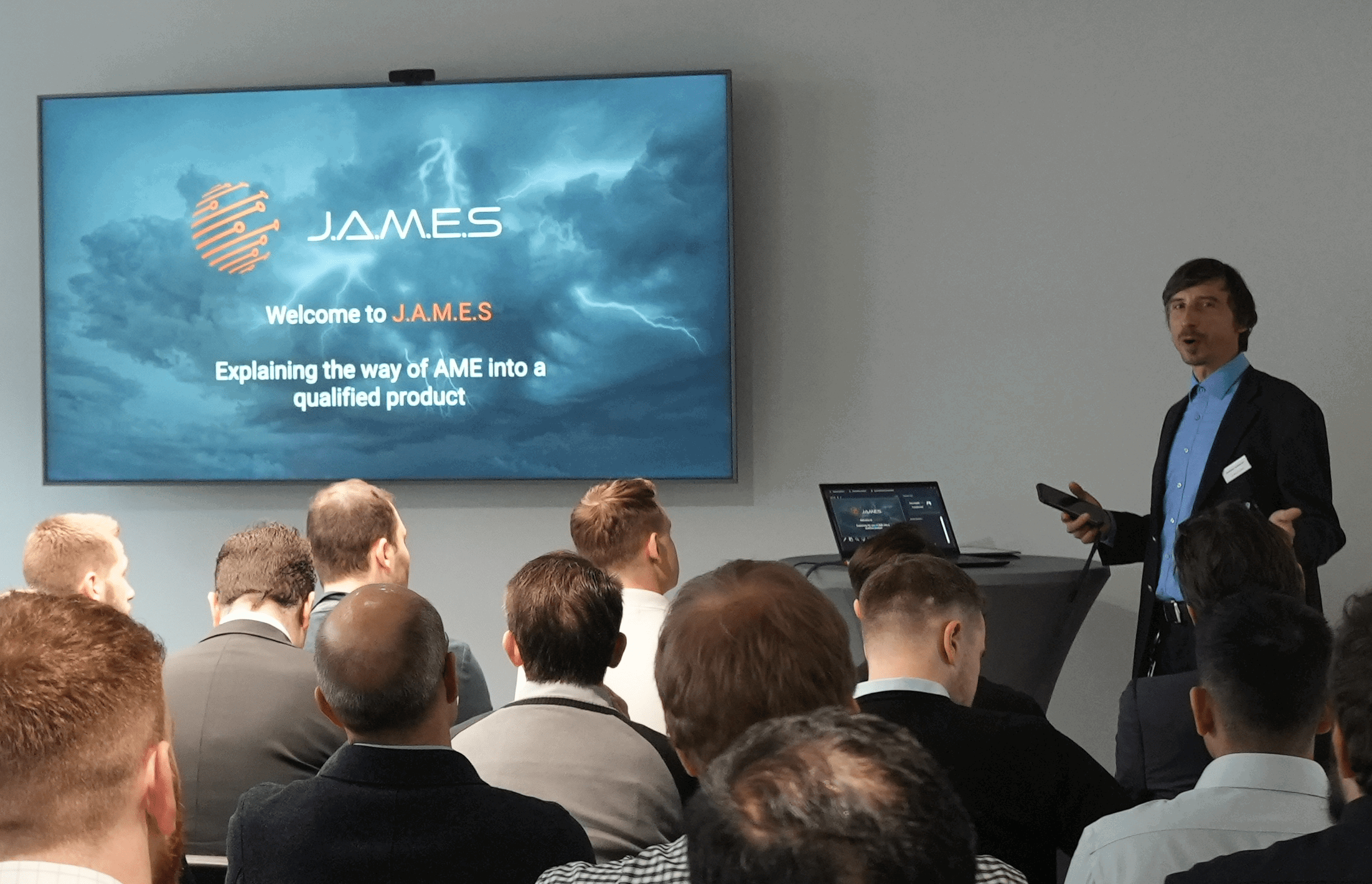

Webinar Recording of Exploring AME: From Concept to Qualified Product

If you would like to gain more insight and knowledge, we invite you to watch our webinar recording on 'Exploring AME: From Concept to Qualified Product'.

Advancing AME Designs: From Research to Production

The industry strives to seamlessly integrate AME designs into customer products. By focusing on scalability, reproducibility, product safety, and qualified manufacturing, joint activities among stakeholders aim to provide manufacturing-as-a-service solutions. The ongoing research activities elevate technology readiness levels, ensuring AME's successful transition from research to production.

At the end of the article, you will have the opportunity to download the PowerPoint slide, providing an in-depth exploration and visual representation of the various topics covered.

Summary of the topic that you will find

- System Design Overview

- Smart System Design with AM(E)

- J.A.M.E.S Vision of AME Environment

- Bringing 3D-Printed Electronics to Product Level

- Ensuring AME Parts-Producibility for the Long Term

- Showcase Application: AME Inlay

- AME Outlook

J.A.M.E.S Vision of AME Environment

This topic specifically emphasizes addressing product and quality issues during the development of new AME products.

Bringing 3D-Printed Electronics to Product Level

J.A.M.E.S identified the needs for production, qualification demands from the industry, and additional topics for quality checks.

Showcase Application: AME Inlay

This example demonstrates the lessons learned when the industry requires a service provider for AME serial production requests, aiming to achieve a certified level of manufactured AME parts.

The Steps of AME Into a Qualified Product Level

The checklist covers material selection, 3D printing optimization, and quality control. By following these guidelines, providers can improve the reliability and efficiency of AME. It also includes best practices for integrating 3D printed components into existing workflows, ensuring seamless production and high-quality results.