AMAREA: 3D Ceramics Waveguide Structures

Design

A first design is finished, a complete explanation of the targeted functionality is included, and the targeted printer technology has been provided. This AME design also provides a model which is proven to fulfill the targeted functionality.

AMAREA® and J.A.M.E.S Engineering are bringing together Multi-Material Additive Manufacturing for mmWave applications. 3D ceramics in RF waveguide use cases by co-printing and co-sintering of conductive and non-conductive ceramic materials.

Innovative Form Factors and Exceptional Performance

With the ability to process multiple materials in one step, such as ceramics, metals, polymers, and composites, Multi-Material 3D printers enable high functionality in components that could not have been achieved before.

AMAREA®'s MMJ Technology simplifies the manufacturing process by going from sequential to direct production. This results in reduced production times and costs.

AMAREA® is also an expert in Multi-Material and understands the importance of premium material quality. Their team, comprising material scientists, ensures that every product meets the highest standards and exceeds expectations.

3D-Ceramics Is Touching RF- and MmWave-Applications

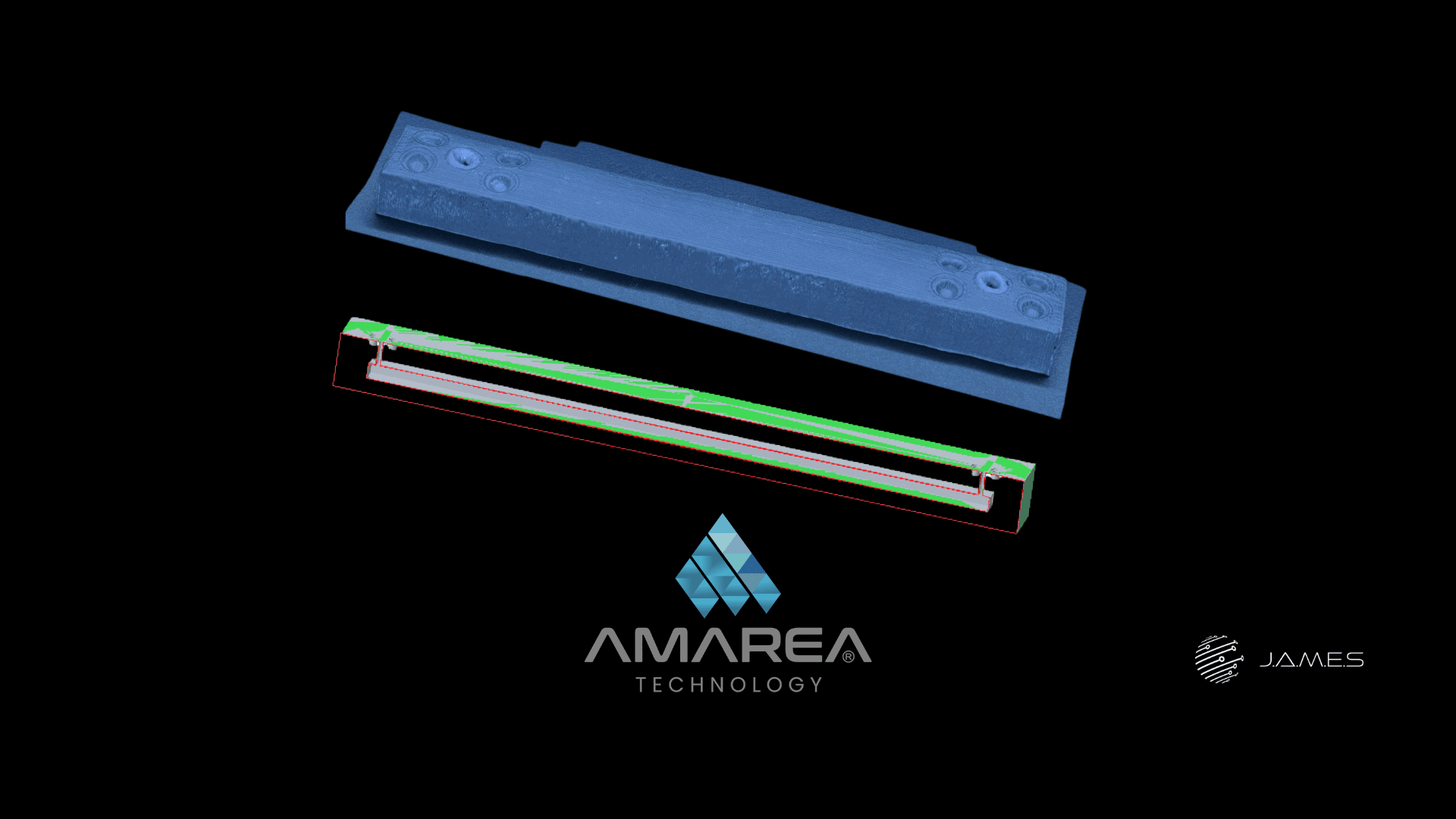

Topic: "Waveguide Filter"

For the First Time AMAREA Brings

3D Print Fully Metallized RF Cavity Resonator Structures with mmWave Inserts

Achieve the vision of:

- No additional mounting requirements

- RF-functional waveguide feeds, filter elements, etc.

- High-performance 3D ceramics designed for harsh environmental conditions

Experience fixed and robust RF performance over a wide temperature range.

What Makes AMAREA Unique

More AMAREA examples that make it special.

Driving High-Tech Research Through Partnership Collaboration

If you are interested in the technology behind this, please contact AMAREA® or use J.A.M.E.S services.

The MMJ ProX Series

Now available to order !

Combine Material Properties with the brand new » MMJ ProX « 3D printing system.

Related Articles

Lithoz Combine Metal & Ceramic By Multi-material 3D Printingj And Join At RAPID TCT

Horizon Microtechnologies Presents "D-band Horn Antenna" At EuMW 2024