The New Multi Material Jetting » MMJ « Pro X - Series

AMAREA Technology introduces the MMJ ProX Series – an advanced 3D printer for creating multi-functional parts with multiple high-performance materials in a single print job.

Powered by Multi-Material Jetting » MMJ « technology, the MMJ ProX Series offers exceptional flexibility and precision for producing highly functional, complex, and miniaturized parts.

Additively manufacture Multi-Material components using a range of materials, including ceramics, high-alloy steels, precious metals, and more.

Accelerate development, simplify manufacturing, and reduce costs by replacing complex assemblies with MMJ-printed parts across industries such as semiconductors, aerospace, defense, energy, packaging, automotive, and luxury goods.

The modular design allows easy pre-configuration and upgrades to meet evolving production needs.

Table of Contents

MMJ ProX Series - System Overview

1 | Stand-Alone Machine

Self-sufficient, measurements: 2500 mm x 1150 mm x 1930 mm, no additional cleaning machinery necessary.

2 | Laser Safety Housing

Safe operation for ablation, smoothing, and structuring with the optional laser module.

3 | Rigid Steel Frame

Maximum stability for additively manufacturing high-precision parts.

4 | Large Front Door

Safe and easy access to the build area, supporting fast print bed swapping. Equipped with additional safety panels when the optional laser module is installed.

5 | High-Quality Motion System

Rapid and precise movement in all three axes with a 20 μm accuracy level per axis.

6 | Additional Print Head Control

Positioned below the build area, head control remains easily visible and accessible during developer mode or maintenance.

7 | Flush Signal Lights

7.1 Dedicated signaling for optional laser operation.

7.2 Real-time operation and status monitoring.

8 | User-Friendly Control Panel

8.1 Large 24" touch display for effortless software control of all machine functions, including parametrization, slicing, 3D printing, analysis, and more.

8.2 Illuminated stainless steel buttons and an emergency stop switch for quick actions.

9 | Secured Access Interfaces

Future-proof design compliant with the latest EU Machinery Regulation 2023/1230, effective January 2027.

10 | Air-Conditioned Control Cabinet

Conveniently side-mounted, ensuring reliable operation in various environments.

11 | Extendable Air Maintenance Unit

Optimally accessible for compressed air systems.

12 | Integrated High-Performance Workstation

First-class performance for an efficient Multi-Material Jetting workflow, powered by the latest Intel Core i9 processor, AMD Radeon RX 7800 XT graphics, and 64 GB DDR5 RAM, enabling seamless build job execution.

13 | Adjustable Stainless Steel Feet

High load capacity for a solid stand and optimal machine leveling.

MMJ ProX Series - Build Area With Advanced Functional Modules

1 | Print Heads

Innovative pneumatic shockwave jetting heads operate at up

to 8 bar air pressure. The system supports a flexible configuration

of up to six print heads with an intuitive quick-release setup

for fast and easy changes of heads, nozzle sizes, and materials.

2 | Print Bed

2.1 Heatable print bed for (green) part build sizes of up

to 530 x 300 x 200 mm³ and multiple print bed zones. Rapid

release mechanism for quick and easy print bed swapping

for effortless part removal and maximized uptime (2.2).

3 | Laser Profile Sensor

High-precision laser-based sensor, as a standard feature,

used to capture 3D surface profiles of deposited materials,

enabling inference on droplet and layer characteristics,

as well as build process documentation and optimization.

4 | High-Precision Pulsed Fiber Laser

Available as powerful upgrade, the pulsed high-precision fiber

laser (1064 nm wavelength, nanoseconds pulse range) enables

optimized MMJ-inline surface processing, from surface

ablation, to smoothing, to structuring at very high resolution.

5 | Extraction System

Specifically designed to complement the optional

» High-Precision Pulsed Fiber Laser « upgrade. This accessory

ensures the safe and efficient extraction and filtration

of material particles and vapors during laser processing.

MMJ ProX Series - Control Unit and Software

The MMJ ProX Series is a complete additive manufacturing platform, integrating high-performance hardware with specialized control software for Multi-Material part production.

The system’s large 24” multi-touchscreen enables direct loading of .3MF files from USB or network sources.

The 3D Manufacturing Format .3MF, an open-source file type developed by Microsoft, is now widely supported by industry leaders like Autodesk, Dassault Systèmes, and Ultimaker (more at 3mf.io).

Design your Multi-Material parts in your preferred software, save as a .3MF file, and upload it to the MMJ ProX. The integrated slicer breaks the component down into a point cloud, with each point representing the coordinate of a drop and maps materials from the print heads to the designated colored volumes in the .3MF file.

To support the production of your unique parts and development of custom materials, the system is fully open, allowing complete parameter customization.

To keep the complexity, caused by the great flexibility of the parameterization, for the user to a minimum, the system’s high precision profile sensor captures detailed topological data of each layer, from droplet characteristics to 3D surface profiles.

Software upgrades and updates help your MMJ ProX system to get better over time.

Looking ahead, advanced smart features will increasingly assist » and even automate « your optimization processes. Speaking of future innovations, the optional high-precision pulsed fiber laser module, available pre-installed or as an upgrade, enables hybrid manufacturing (additive + subtractive). Upcoming software updates will unlock laser smoothing, ablation, and structuring for layers and surfaces, further expanding your manufacturing

system‘s capabilities.

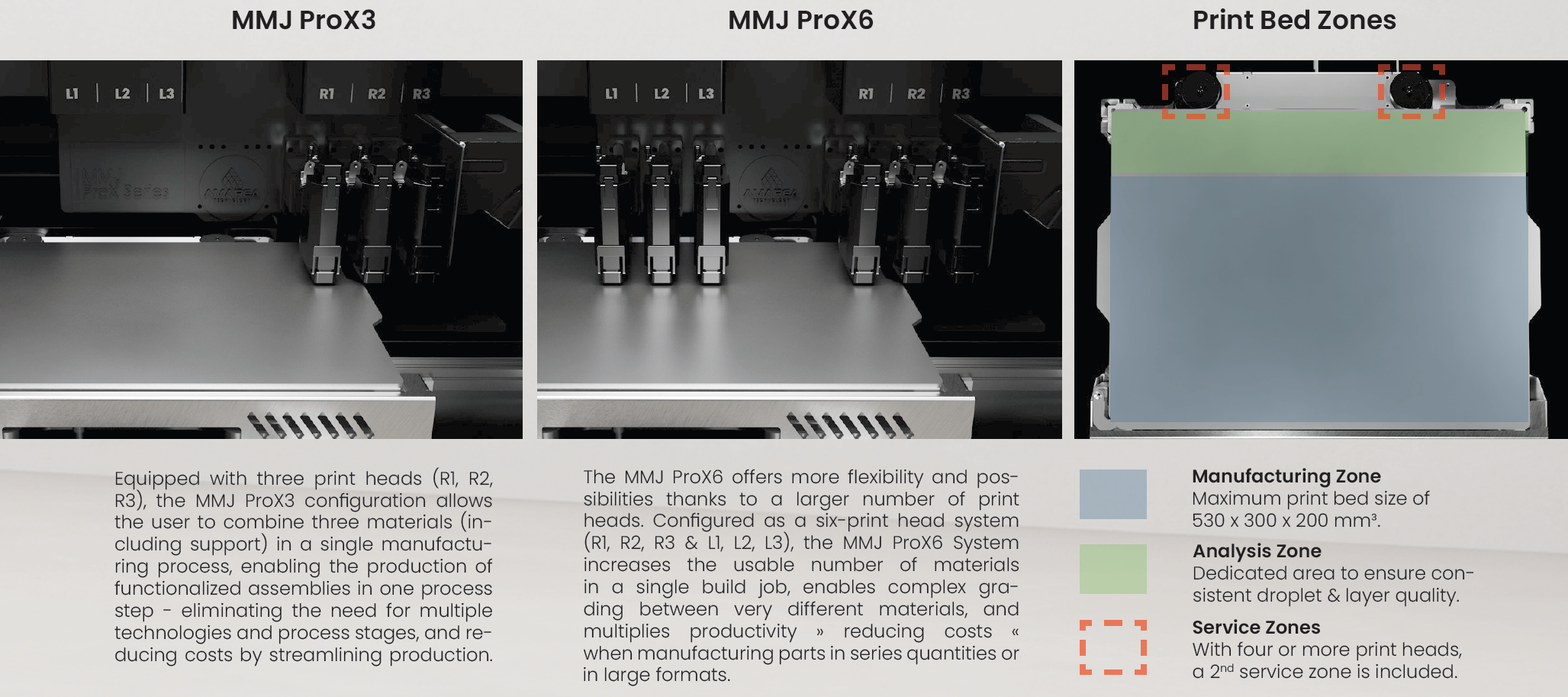

MMJ ProX - Series - Configure to Your Needs - Upgrade Anytime

The MMJ ProX is designed as a modular system to adapt to your specific needs and future requirements.

Configurations can include multiple print heads, allowing for 3D printing with different materials in a single build job.

This enables the integration of functional details with voxel-level precision, paving the way for unprecedented miniaturization

and functional grading. Prioritizing both safety and flexibility, all configurations come standard with a laser safety housing

featuring a large transparent pane door. This MMJ ProX Series design ensures uncompromised visibility for process monitoring

with the human in the loop and allows for future expansion with the optional laser module.

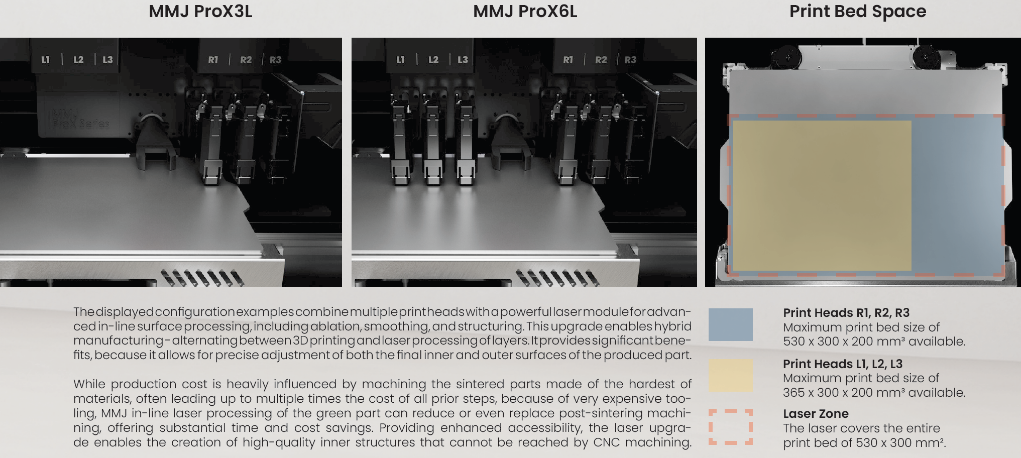

MMJ ProX - L Series - Boost Your AM Power - Upgrade With the Laser Processing Module

To enhance the advanced manufacturing capabilities of the MMJ ProX, a laser module can be installed. When the module is added, the

laser safety housing is equipped with a laser-safe door insert. This insert features laser safety glazing, allowing direct operator

monitoring while the laser module is active. Additionally, an extraction system ensures the safe and efficient removal, and filtration

of material particles and vapors during laser processing. The L-Package can come preinstalled or be added later, conveniently

transforming your MMJ ProX configuration into the even more powerful MMJ ProX L.

Related Articles

Exploring Materials In 3D Printing: Metals, Ceramics, And Polymers

Multi Material Jetting MMJ Technology Explained By AMAREA

ACI High Resolution Printable Semi-Sinterable Silver Conductor - FS0142