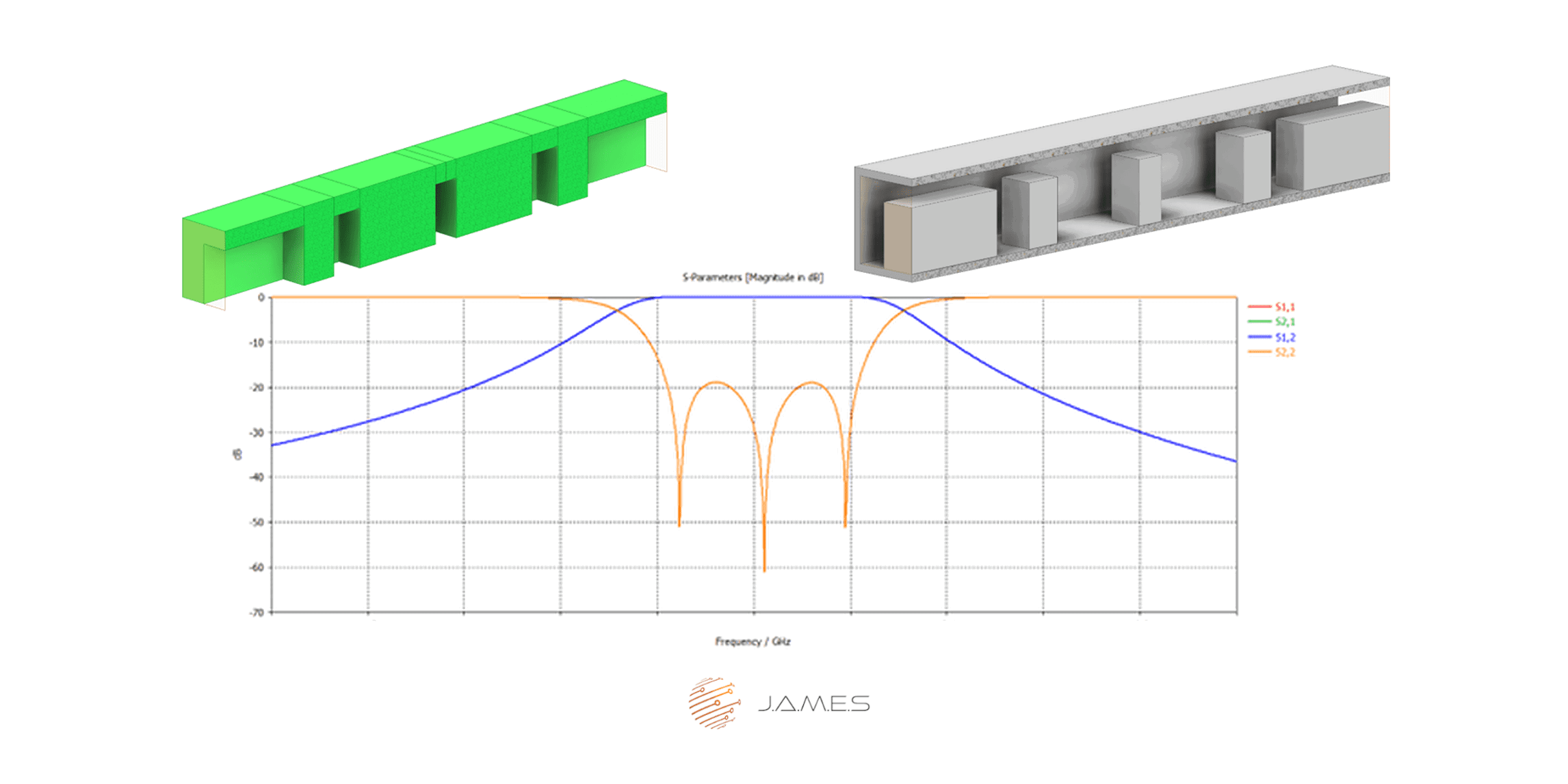

Additively Manufacturing Of High-Frequency Waveguide Filters

Concept

This AME design has the status of concept. A first design concept is established, a complete explanation of the targeted functionality is included, and the targeted printer technology has been provided.

This article explores the benefits of using Additive Manufactured Electronics (AME) to create high-frequency waveguide filters. The key advantages include:

- Excellent RF performance

- Lightweight design

- Reduced manual assembly and tuning

- Enhanced long-term stability

Traditional RF Waveguide Filters:

It requires

- Extensive mounting efforts to ensure RF tightness

- Numerous screws

- Manual tuning for optimal RF performance, such as high RF blocking attenuation and sharp separation of pass and stop bands

High-frequency RF-Filters for product use-case e.g.

- Avionics

- Defense and Space

- Automotive

These filters are part of our technology roadmap to enhance performance through additive manufacturing.

Benefits of Lightweight Filters:

Achieving high-performing, lightweight filter elements increases system benefits. For instance:

- Satellite equipment for space communication becomes lighter

- Aircraft can achieve longer flight durations

The J.A.M.E.S Design activities will be supported by our partners to provide innovative drive and maintain constant focus on product requirements and industry needs, leveraging an established partner in this business area.

Acknowledgements : We appreciate the support of Jonas Weindl and Alexander Paulus from TU-München, Chair of High-Frequency Engineering.

Realization Checkpoints:

To achieve excellent electronic results, we must check:

- Structural body realization (potentially via AM)

- Sharp edges

- AM with support material

- In-body accuracy

- Parallel walls

For electronics and RF performance, a conductive surface is essential. Considerations include:

- Complete AM conductive metal structure

- Surface oxidation checks

- Selection of conductive material

- Border effects for precious metal transitions

- Corrosion and demodulation effects

- Conductive surface thickness

- Combining structural bodies with post-metallization processes

- Restrictions in metallization processes

- Maximum metallization thickness

- Edge accuracy post-metallization

- Basic metallization stability (e.g., for connector implementation)

Operational Requierements:

Operational requirements for AM/AME printing or post-metallization processes include:

- Weight

- Degree of miniaturization

- Mechanical stability

- Electronics performance (e.g., RF filter behavior) with own electrical requirements.

- Environmental loads (e.g., salt, sand, dust, humidity, temperature range)

- Delamination stability

- Chemical robustness (e.g., for airborne equipment), you have to be careful with these requirements! Electronic applications, such as those in a UAV, do not really encounter kerosene or deicing fluid impacts.

Decision Factors:

The decision to use these filters depends on their performance and system benefits. If RF performance is significantly improved, resulting in a lighter system element, it can serve as a perfect tuning component for larger systems. Systems engineers, project leaders, and quality/safety engineers will decide based on performance.

It is necessary to mention that larger systems can effectively distribute mechanical or environmental loads to a new component if it enhances performance. New components can be integrated into a modern and intelligent housing concept to protect them from harsh environments.

Sometimes, it's simply an innovative decision to propel new technologies and applications towards product development.

Related Articles

Enhancing Smart Ski Goggles With Additive Manufacturing Electronics (AME) Technology