Hybrid Additive Manufacturing: The Best Of Both Worlds In Production

Additive manufacturing processes like 3D printing are changing the game. However, they have their limitations, and in some cases, traditional manufacturing processes are required to achieve the desired result.

This is where hybrid manufacturing comes into the picture—a strategy that combines the best of both additive and traditional manufacturing. This approach allows engineers and manufacturers to take advantage of the benefits of 3D printing without letting go of results that are only possible—for now—with subtractive techniques like machining.

Let's explore hybrid additive manufacturing and its potential.

How Hybrid Manufacturing Works

Hybrid manufacturing is a two-step process. The initial form is 3D printed before being refined using subtractive techniques. The first step is to create the intricate and complex geometries that traditional manufacturing cannot produce. The second refines the surface and improves the mechanical properties.

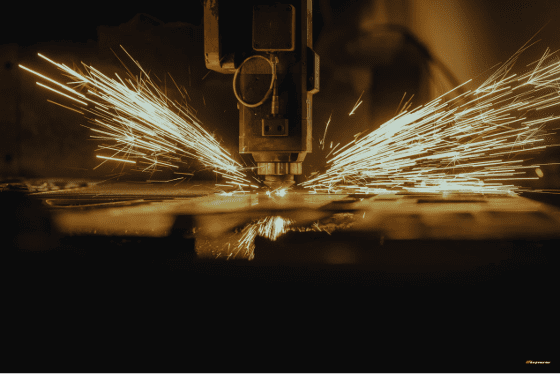

One common use case is metal 3D printing. The 3D printer produces a rough metal part, which is then transferred to a CNC machine for precise shaping and finishing.

There are two main ways the above process can be achieved: using a single machine and using separate machines.

- The first option combines both additive and subtractive processes into a single machine. For example, a manufacturer might augment a CNC machine with 3D printing capabilities. The benefit of this approach is that the machine can switch between additive and subtractive processes as many times as needed without manual intervention.

- The second option involves moving a part between multiple machines. Say a 3D printer creates a blank component. An employee would then move this to a CNC machine for the finishing touches. This is a lengthier approach but is more accessible, at least for now.

Why Hybrid Additive Manufacturing?

Hybrid manufacturing fills in the gaps. It compensates for the limitations of 3D printing technologies, particularly those related to the types of materials they support and finishes they are capable of achieving.

The most common use case for this approach is, as mentioned, metal additive manufacturing. 3D printing creates near-net shapes, but these require post-processing. Using a CNC machine for post-processing is the most efficient way to fabricate complex internal and external features for high-performance parts. The CNC machine can cut away any excess material, drill holes, fill in cracks, sand or colour surfaces, and so on.

Challenges and Opportunities

Integrating traditional and additive manufacturing opens doors to new and exciting possibilities for many different industries. However, there are several challenges we must overcome before we reach a future where 3D printing and subtractive technologies work together.

The first is developing machines that use both processes to their full potential. Manufacturers will then need skilled team members to operate this cutting-edge equipment. This challenge presents a big opportunity for innovators in the manufacturing space.

Another potential challenge is the risk of increasing material waste. 3D printing is a low-waste manufacturing approach, so incorporating subtractive technologies into the process means increasing waste production. Whether this drawback is worth the benefits of hybrid manufacturing will depend on a company's needs and values.

Finally, hybrid manufacturing, by its very nature, demands longer post-processing times compared to 3D printing alone. Manufacturers will need to account for this extra time to ensure they continue to deliver on customer expectations.

Image via https://unsplash.com/photos/a-piece-of-metal-being-cut-with-a-machine-fBCQz7OUUww

Related Articles