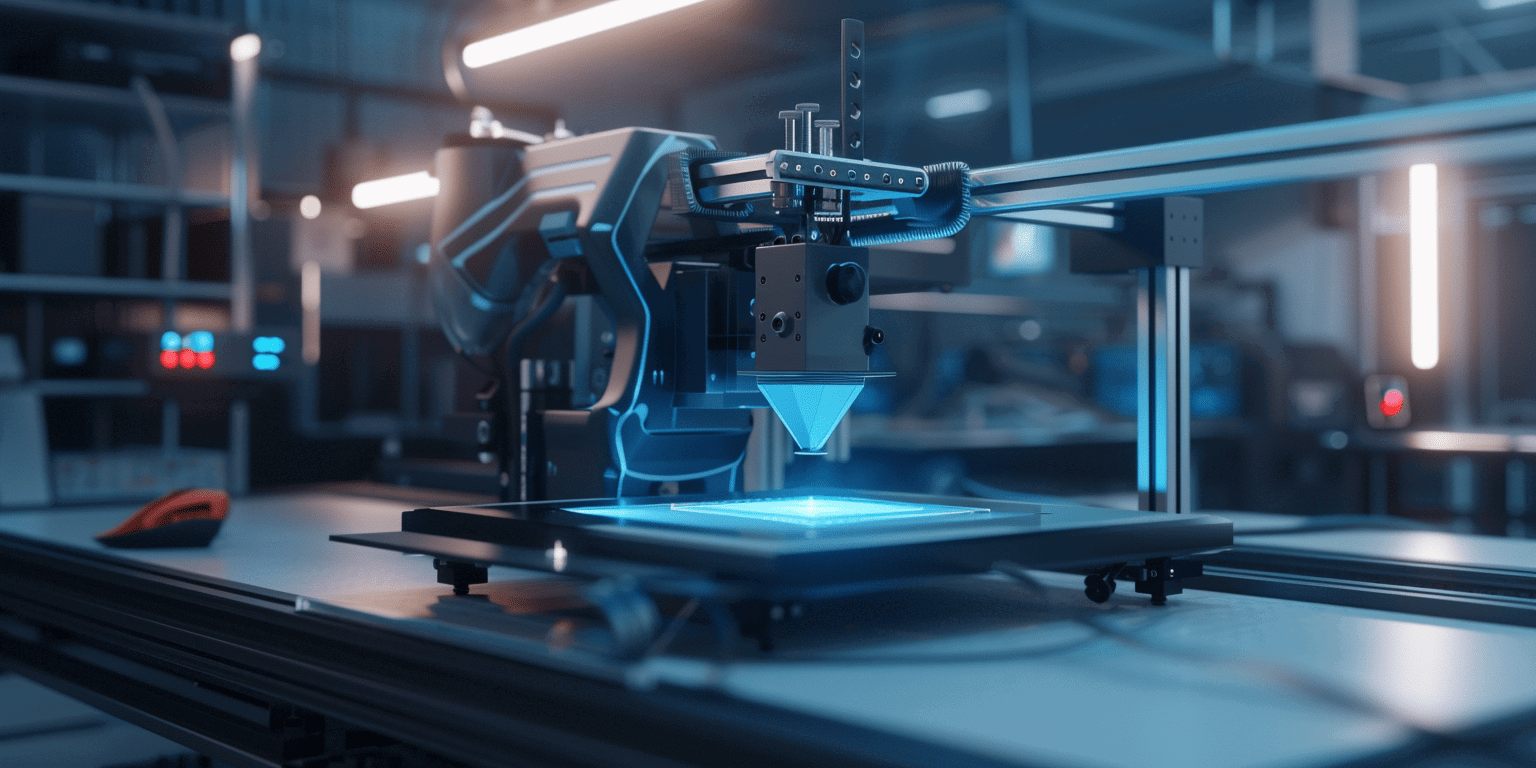

Multi-Material 3D Printing: A Transformative Breakthrough In Manufacturing

The field of digital manufacturing is experiencing a revolutionary change with the emergence of multi-material 3D printing. This innovative technology, described in the research by Steve Ready, Gregory Whiting, and Tse Nga Ng from the Palo Alto Research Center, introduces us into a future where the integration of various materials and embedded electronics within 3D-printed objects becomes feasible.

Expanding Horizons Beyond Traditional 3D Printing

Traditional 3D printing primarily focused on creating mechanical structures from a limited set of materials, typically plastics or metals. However, these were often restricted to prototyping stages, with final products manufactured through conventional methods. Multi-material 3D printing transcends these limitations by enabling the combination of different materials, including plastics with varying properties and metals, to create objects with embedded optical and electrical functionalities. This innovation allows for the production of complex structures that are otherwise unachievable with existing manufacturing techniques (Ready, Whiting, and Ng, 2014).

Overcoming Material and Processing Challenges

The transition from single-material to multi-material 3D printing introduces several challenges, notably the need to manage a variety of materials with differing properties and processing requirements. Key parameters for successful multi-material printing include ink rheology, surface energy, adhesion, solvent compatibility, dimensional stability, and optimal processing conditions. Addressing these parameters ensures the reliable performance of the printed object, both mechanically and electronically (Ready, Whiting, and Ng, 2014).

Advanced Printing Technologies and Methods

The research highlights the use of advanced printing technologies such as ink jet, aerosol jet, and extrusion deposition. For instance, inkjet printing, with its high-resolution capabilities, enables the precise deposition of materials like conductive silver paste to form complex electronic circuits. Additionally, extrusion methods allow for the use of epoxies, acrylates, and urethanes, which are cured using UV or thermal treatments between layers (Ready, Whiting, and Ng, 2014).

Design Software: Ensuring Precision and Functionality

A crucial element in the multi-material 3D printing process is the sophisticated design software. This software not only facilitates the modeling and analysis of complex designs but also ensures the structural integrity and functionality of the printed object. It provides automated feedback on potential design flaws, optimizes tool paths for the print heads, and supports non-planar deposition capabilities, making it indispensable for achieving precision in multi-material printing (Ready, Whiting, and Ng, 2014).

Conclusion: The Future of Multi-Material 3D Printing

Multi-material 3D printing stands at the forefront of digital manufacturing, heralding a new era where the integration of diverse materials and embedded electronics within 3D-printed objects is not just possible but practical. This technology promises to revolutionize the manufacturing industry, offering unprecedented design freedom and the ability to create functional, complex structures previously unattainable through conventional methods.

Building on the findings of Ready, Whiting, and Ng (2014), it's clear that multi-material 3D printing is poised to dramatically shift how products are designed and manufactured. The integration of various materials and electronic components within a single 3D-printed object opens up new possibilities for innovation in numerous fields, from healthcare to aerospace. The key challenge will be developing compatible materials and refining the printing processes to ensure reliability and performance. As this technology matures, we can expect a significant impact on both prototyping and final product manufacturing, making multi-material 3D printing a cornerstone of future manufacturing technologies.

Reference: Ready, S., Whiting, G. and Ng, T. (2014) 'Multi-Material 3D Printing', Palo Alto Research Center, 3333 Coyote Hill Road, Palo Alto, CA 94304.

Related Articles

Mastering 3D-Printed Electronics: J.A.M.E.S Magazine's Latest Edition