The Journey And Evolution Of The J.A.M.E.S Coin

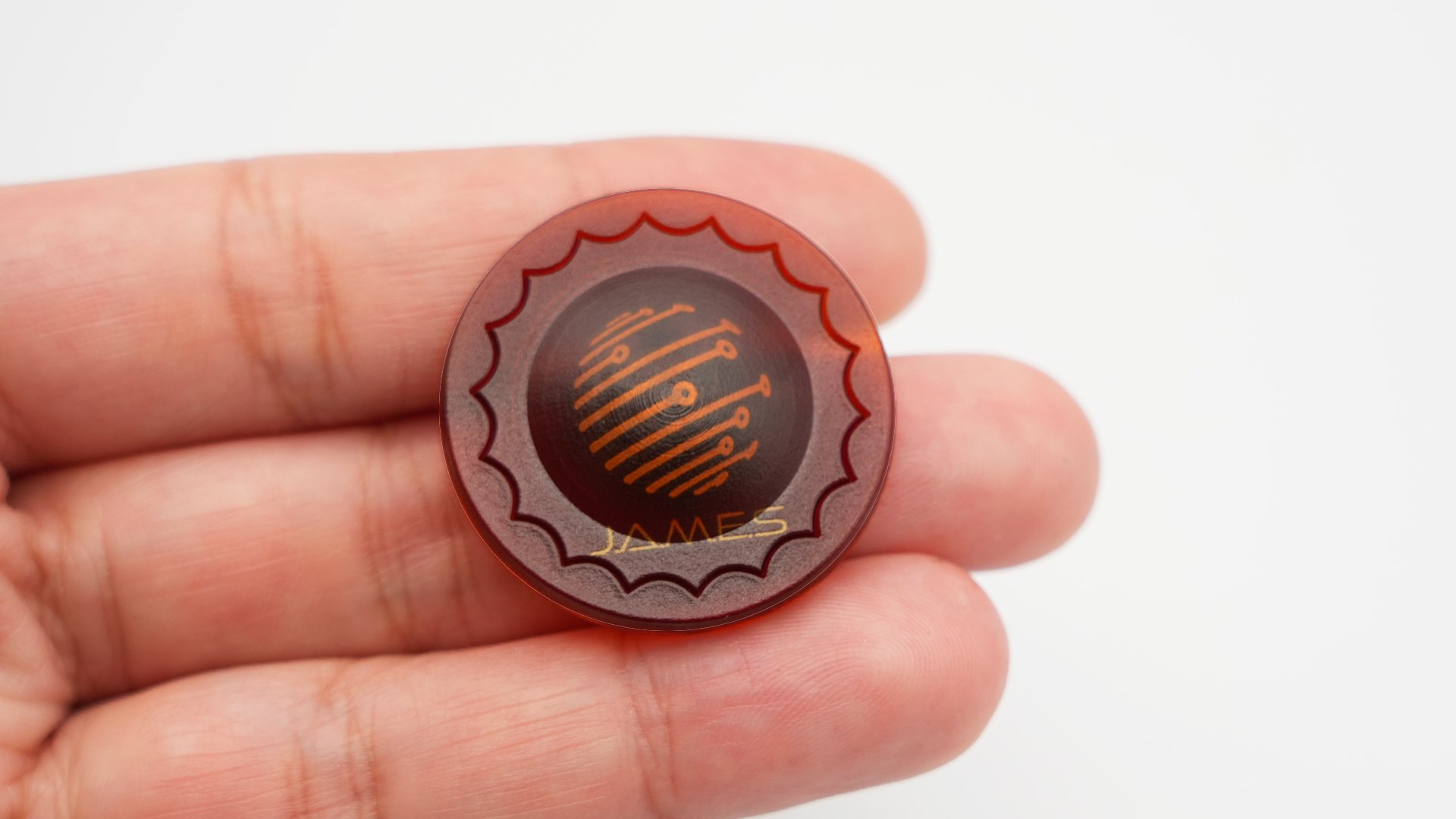

The J.A.M.E.S Coin is our easy entrance story for Additively Manufactured Electronics (AME). The very first thought was to have a design in the form factor of a 2 Euro coin.

The Inspiration Behind J.A.M.E.S Coin

The inspiration for the J.A.M.E.S Coin was to find an easily accessible and functional design with a suitable size for a giveaway. As an easy entrance story to AME it should show the evolution from a surface-populated 2.5D-design to a full 3D-wired structure with directly imprinted passive components. The goal was to show the capabilities of AME and to have a comparable benchmark application for other AME processes.

Key Design Iterations

J.A.M.E.S Coin NFC on AME Freestyle

- This design features a 3D-designed housing, demonstrating the versatility of AME in fabricating intricate structures.

- Implemented in a multicarrier panel for the fast population with a Pick-and-place machine.

- The thin design vastly reduces printing time, enhancing cost and time efficiency for producing large quantities of giveaway applications.

- By implementing a side-mounted LED with a cone to canalize the light and an optical fiber-filled cavity, the LED can illuminate the whole coin.

- Directly-printed capacitors, saving time and effort for population.

- Highlights the potential of integrating functional capacitors directly within the structure.

Advantages of AME Components

With direct-printed passive components such as antennas, inductors and capacitors, we can eliminate the need for a separate population while improving manufacturing efficiency. With Direct-printed components, we eliminate losses at the solder pads and enable the possibility to simulate, tune and realize the circuit without manual tuning. This integration gives us more space on the surface, and combined with traces that use the full 3D-volume of a structure, it enables us to create all sorts of arbitrary-formed electronics with embedded components. The story shows how customizable, compact and efficient future applications based on AME technology can be.

Comments

Related Articles