NRugged 3D Zero G Flight

The @nscryptinc team successfully demonstrating ODME printing processes during a zero-gravity parabolic flight using the nScrypt Inc. nRugged 3D manufacturing system, optimized for the ISS and featuring an advanced toolplate able to accommodate nine toolheads.

Successfully Demonstrating ODME Printing Processes During a Zero-Gravity Parabolic Flight

using the nScrypt Inc. nRugged 3D manufacturing system, optimized for the ISS and featuring an advanced toolplate able to accommodate nine toolheads.

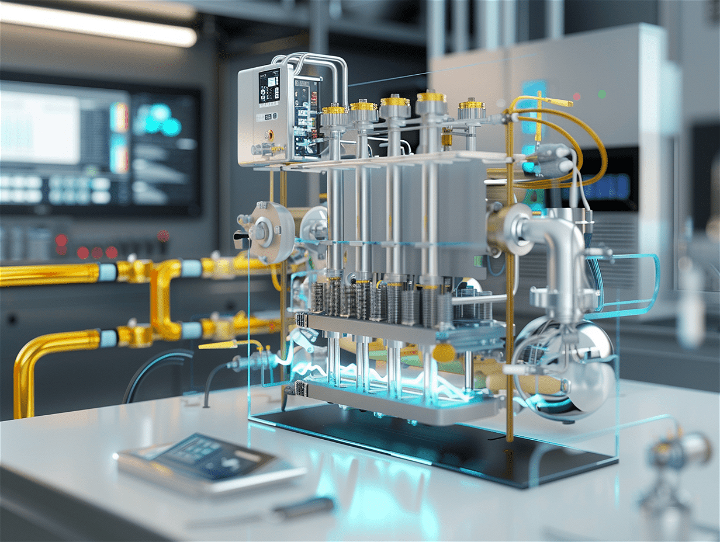

The nRugged 3D Manufacturing System

The FIRST and ONLY precision 3D manufacturing/bioprinting platform for harsh environments.

using the nScrypt Inc. nRugged 3D manufacturing system, optimized for the ISS and featuring an advanced toolplate able to accommodate nine toolheads.The nRugged is the ruggedized version of nScrypt's direct digital manufacturing platform (Factory in a Tool (FiT)), factory-configured for either 3D manufacturing or bioprinting with automatic tool changes. For example, a complete electronic device or a bioactive bandage can be digitally manufactured in the same machine. The bioprinter configuration can print both biologics and non-biologics with a broad palette of materials. nRugged solves the problem of manufacturing of a precision product, not just a part, in harsh environments, like on a Navy ship in rough waters or on the back of a trailer.

nRugged Features

- Up to four tool heads

- 3D Manufacturing Configuration: Smartpump™, nFD™, nMill™, and nPnP360™ for FiT Solutions

- Biomanufacturing Configuration: 3 Smartpumps™ and 1 nFD™ for Biomanufacturing solutions

- 10,000+ materials

- 238 mm x 173 mm travel in XY

- 152 mm travel in Z

- 150 mm x 150mm heated print bed

- No external compressed air is required

- Powered by 25-28VDC or 100-240VAC

- Runs up to 48 hours with the battery option (battery can be solar charged)

- Weight: ~ 220 lbs. (depending on configuration and options)

nRugged Options

- In-process monitoring and control with: target view camera (for microscopy and X-Y alignment)

- Process view camera (For live view of the printing tip)

- Keyence line scanner or point sensor

- 4 channel heater controller

Comments

Related Articles

Leading The Future In 3D Printing Technology And Manufacturing