The Art Of 3D Ceramics And AMEfication Perspectives

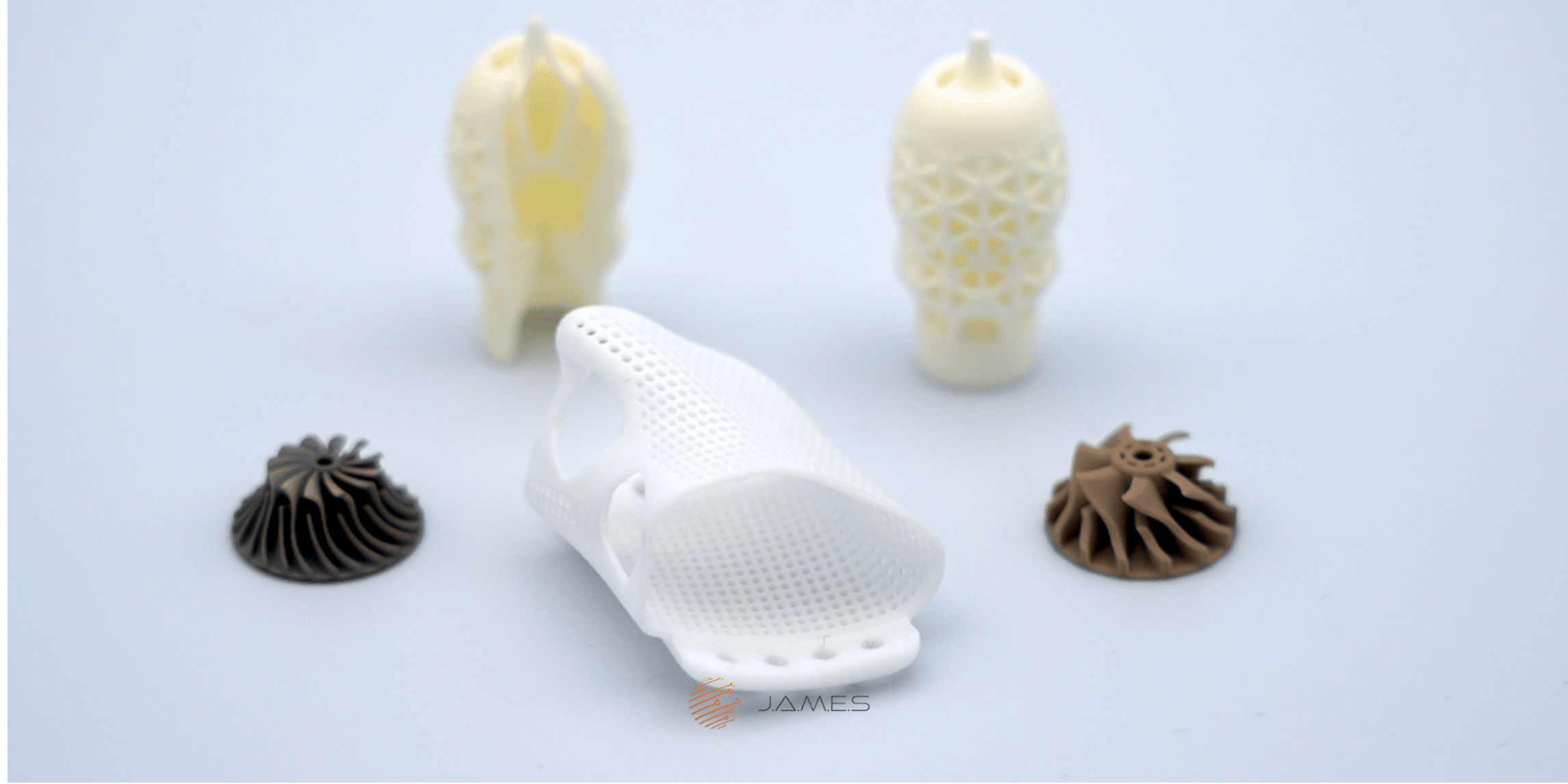

Fabricating 3D form factors with extremely robust materials and achieving 3D electrification for RF use cases seem to be one of the most promising applications for AME.

Material-Ceramic

- the ultimative choice for harsh operational conditions

- for mechanical robustness

- to withstand highest temperatures

- to withstand harmful substances

- for biocompatibiliy and recycling issues

- the enabler for high frequency applications

- lowest dielectric loss factors

- high dielectric constant

3D Ceramic Manufacturing Process

- reach out full 3D formfactors in high surface quality

3D Ceramic AMEfication

- Combine 3D Smart System design strength with best material properties (mechanical and electrical) for electrified high performance applications

- come closer to HOT & HARSH operation

- come closer to High Power Electronics

3D Ceramic for RF- and MmWave-Applications

touching the highest frequencies

3D Ceramic for Special Electro/optical Applications

- Indeed - this material gives an additional vision - transparent 3D Ceramics

Comments

Andreas Salomon

5mos ago

It is incredible, what's possible in 3D-printing ceramics now!To see 3D printed structures of SiC deeply impresses me - from perspective of high power semiconductors, LED's or ultra broadband RF power amplifiers SiC or GaN on SIC is playing a major role.Imagine new 3D-printed SiC housing concepts for optimal thermal adaptation to the hotspot semiconductor areas...Exciting Vision... isn't it ?

J.A.M.E.S GmbH

0 Likes

0 Likes

FPM-Trinity - World Premiere At The INTERNEPCON JAPAN 2024 In Tokyo

10.01.2024

Featured Partners

About Us

© 2025 J.A.M.E.S GmbH.