Voltera - Printing Electroluminescent Ink On Paper And PET

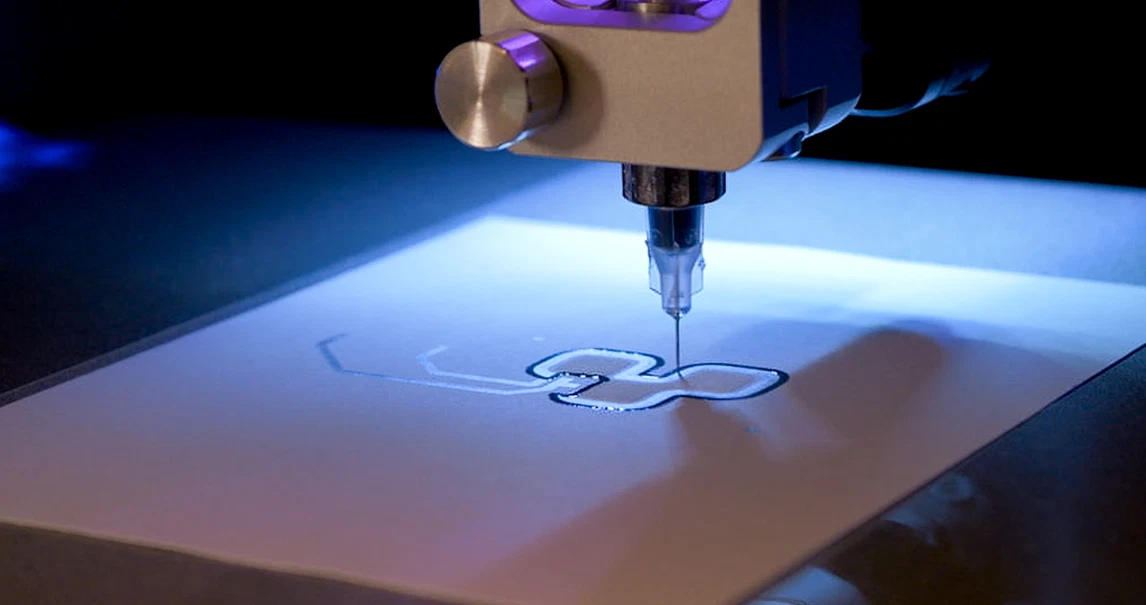

Electroluminescent inks are popular for their consistent brightness, low cost, and high energy efficiency, making them suitable for various display applications. This research paper demonstrates printing electroluminescent ink on flexible substrates, namely paper and PET, using the Voltera NOVA to print the Voltera logo.

Project Overview

Purpose: Showcasing the multilayer printing capability of the Voltera NOVA by creating a blue light-emitting Voltera logo on paper and PET.

Design Layout: Electroluminescence works by exciting a phosphor material with an electric field, requiring an inverter to convert direct current to alternating current. The design involves:

- Base Conductive Layer:

- Ink: Saral Silver 700 Silver-Based Conductive Ink

- Substrate: Cardstock paper, PET

- Nozzle: Nordson EFD 7018424 dispensing tip (0.15 mm)

- Cure: 5 minutes at 120°C

Dielectric Layer:

- Ink: Saral Dielectric 600 Dielectric Ink

- Substrate: Cardstock paper, PET

- Nozzle: Nordson EFD 7018333 dispensing tip (0.25 mm)

- Cure: Air dry 10-20 minutes

Phosphor Layer:

- Ink: Saral BluePhosphorL 800 Electroluminescent Ink

- Substrate: Cardstock paper, PET

- Nozzle: Nordson EFD 7018333 dispensing tip (0.25 mm)

- Cure: 1 minute at 120°C

Top Conductive Layer:

- Ink: Saral Conducting Polymer 700 Polymer Electrochromic Ink

- Substrate: Cardstock paper, PET

- Nozzle: Nordson EFD Optimum Chamfered Tip (0.1 mm)

- Cure: 5 minutes at 120°C

Desired Outcome

When connected to an alternating current (140 V, 1.862 kHz), the phosphor layer should emit blue light, illuminating the Voltera logo evenly on both paper and PET.

Challenges and Solutions

- Trapped Air:

- Solution: Use a dual asymmetric centrifugal mixer before printing and allow the dielectric layer to dry at room temperature.

Uneven Glow:

- Solution: Address layer thickness, adjust print speed, height, and nozzle size, and add fiducials for better alignment.

Conclusion

Paper Substrate: Consistent results, smoother layers, potential for electroluminescent (EL) displays due to its absorbent nature.

PET Substrate: Flexible, chemically resistant, suitable for demanding applications. Requires fine-tuning of print settings for optimal results.

Both substrates demonstrate the potential for EL display applications, highlighting the versatility and adaptability of electroluminescent inks in various contexts. Future explorations might include printing on glass and other non-conductive substrates, expanding the possibilities of electroluminescent technology.

Watch the Video: Printing the Electroluminescent Logo

In this NOVA print video, we're using Saralon's electroluminescent ink suite to create a version of our logo that, when connected to power, causes the light emitting materials to glow. Take a look at how this entire process was accomplished in just under three hours. Potential electroluminescent applications include high-visibility safety clothing, or automobile displays. Please note, the multilayer function for NOVA is currently under development.

Related Articles