Horizon Microtechnologies - Using The BMF MicroArch S240 System

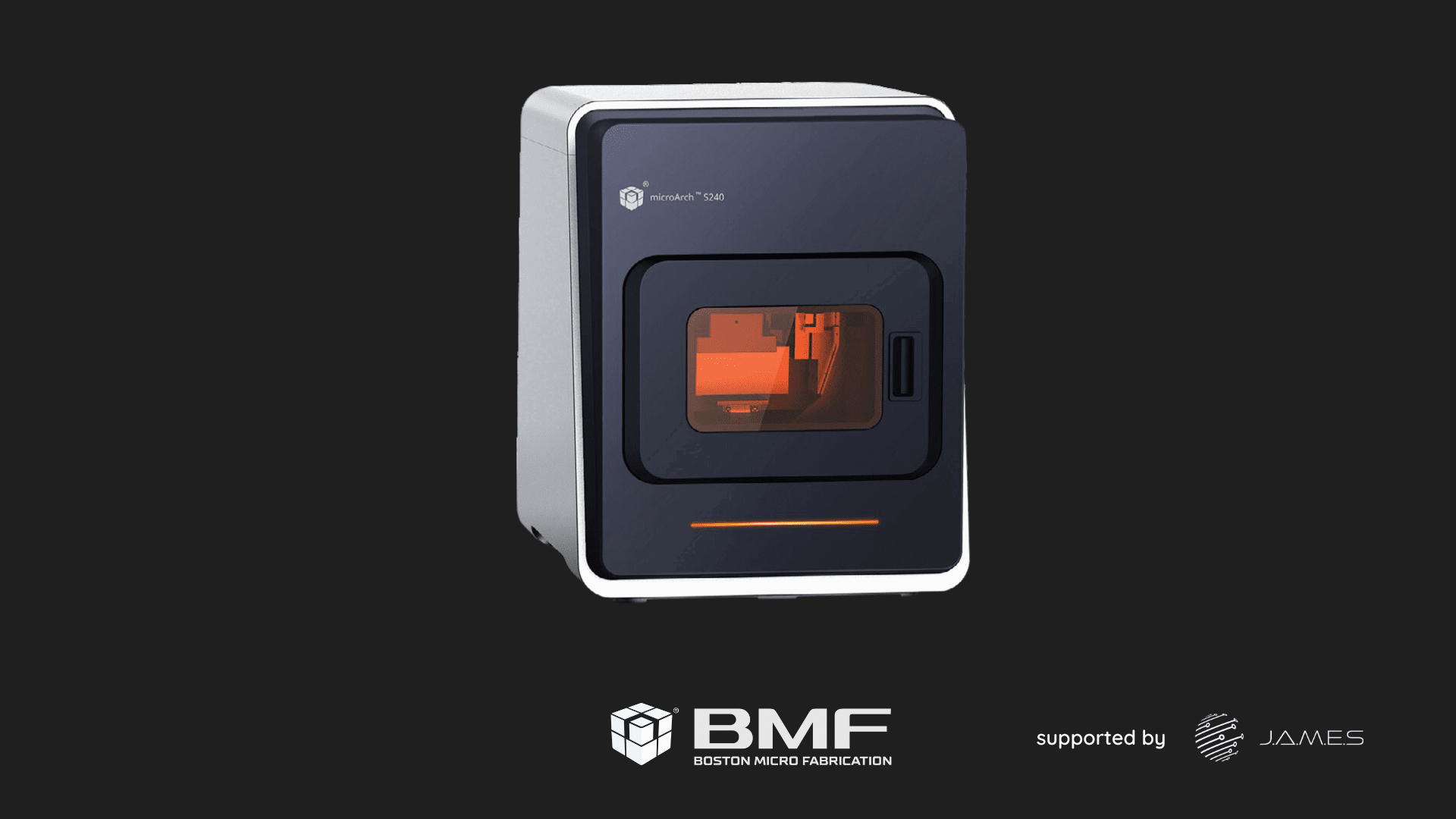

The BMF PµSL System S240 builds extremely intricate parts with excellent precision and tolerance attainment, and comes from BMF’s 10μm series of micro AM solutions, an ideal option for Horizon Microtechnologies, where the requirement is for ultra-high resolution, accuracy, and precision. The S240 can print engineering-grade materials and boasts a large build volume — specifically designed to meet the needs of industrial production.

How the microArch S240 Works

Horizon Microtechnologies is using the BMF MicroArch S240 system to reach out the high accuracy which is needed to

create waveguide structures for high frequency applications.

Have a Look Into the Webinar by Andreas Frölich

to get more insights about the technology behind.

This webinar highlighted the manufacturing of millimeter wave (mm-wave) components by additive manufacturing in combination with coating technologies.

Some Example for Additional Experience With BMF in the US:

Improving Orthomode Transducer Performance With Advanced 3D Printing Technology

In the world of microwave communication systems, Orthomode Transducers (OMTs) play a pivotal role in managing cross-polarized microwave energy. Gregory Peter LaSage, Program Developer/Manager at SLAC National Accelerator Laboratory, embarked on a mission to elevate the performance of these critical components through advanced 3D printing.

Initial Hurdles:

Le Sage's initial attempt used Stereolithography (SLA) technology, but it fell short of expectations. The SLA-printed OMT faced significant performance issues, with an insertion loss of 11 dB at 71 GHz—well above the acceptable threshold. The resolution limitations of SLA, at 50 microns, resulted in inaccuracies that compromised the device's efficiency.

Redesign and Innovation

Determined to overcome these challenges, Le Sage redesigned the OMT for better resolution and mechanical strength. Enter High-Precision DLP 3D printing, also known as Projection Micro Stereolithography (PµSL). Using Boston Micro Fabrication’s (BMF) microArch S240 3D printer, the redesigned OMT achieved the precision necessary for high-frequency applications.

Breakthrough Results

The DLP-printed OMT significantly outperformed its SLA predecessor. With reduced insertion loss and performance levels comparable to top-tier commercial equipment, this advancement underscores the transformative impact of high-resolution 3D printing in the realm of advanced engineering.

Takeaway

This success story highlights the critical role of selecting the right manufacturing technology. The transition from SLA to DLP 3D printing not only solved the resolution issues but also demonstrated the potential for future innovations in high-frequency component design.