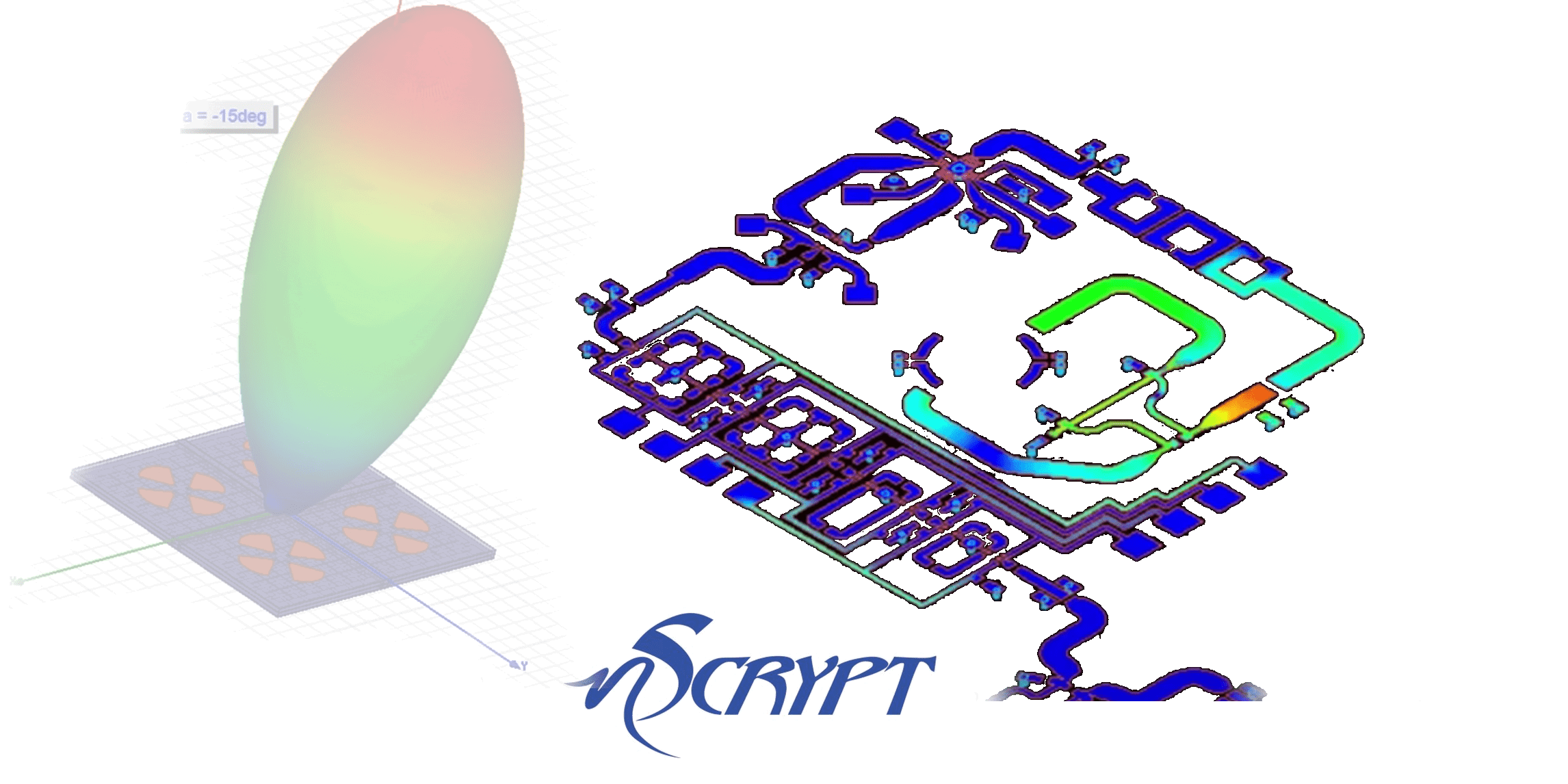

Printed Antennas By "nScrypt"

As the demand for antennas with complex patterns on uneven and doubly curved substrates continues to grow, nScrypt is well-equipped to meet this need. Using nScrypt’s SmartPump™-equipped 3Dn Factory in a Tool manufacturing platform for microdispensing, the range of materials available for printed antennas is significantly expanded. These platforms can handle materials ranging from low viscosity to very high viscosities with heavy particle loading, allowing customers to select the optimal material for their requirements.

nScrypt’s 3Dn Factory in a Tool platform excels in printing on both flat surfaces like Mylar or Kapton as well as 3D shapes and hard, non-flexible surfaces. Their precision motion control platforms enable the conformal printing of advanced antennas on various surfaces, including those used in Smartphones and tablets.

nScrypt's history in phased array antenna technology is notable. In 2016, its research arm, Sciperio, developed the industry's first fully printed seven layer phased array antenna for the U.S. Air Force. This paved the way for conformal phased arrays, allowing antennas to be printed on complex, curved surfaces for advanced communication technology.

nScrypt Realization of a Phased Array Antenna

The World's First 3D-Printed Phased Array Antenna ...

have a look!