Exploring Multi-Material Printing For Rapid Prototyping Of Multilayer Hybrid Ceramic Components

This technical article is created by following authors:

Prashantkumar Pandey and Steffen Ziesche, Fraunhofer Institute for Ceramic Technologies and Systems IKTS

Lopec 2024 Poster Session

Key Points

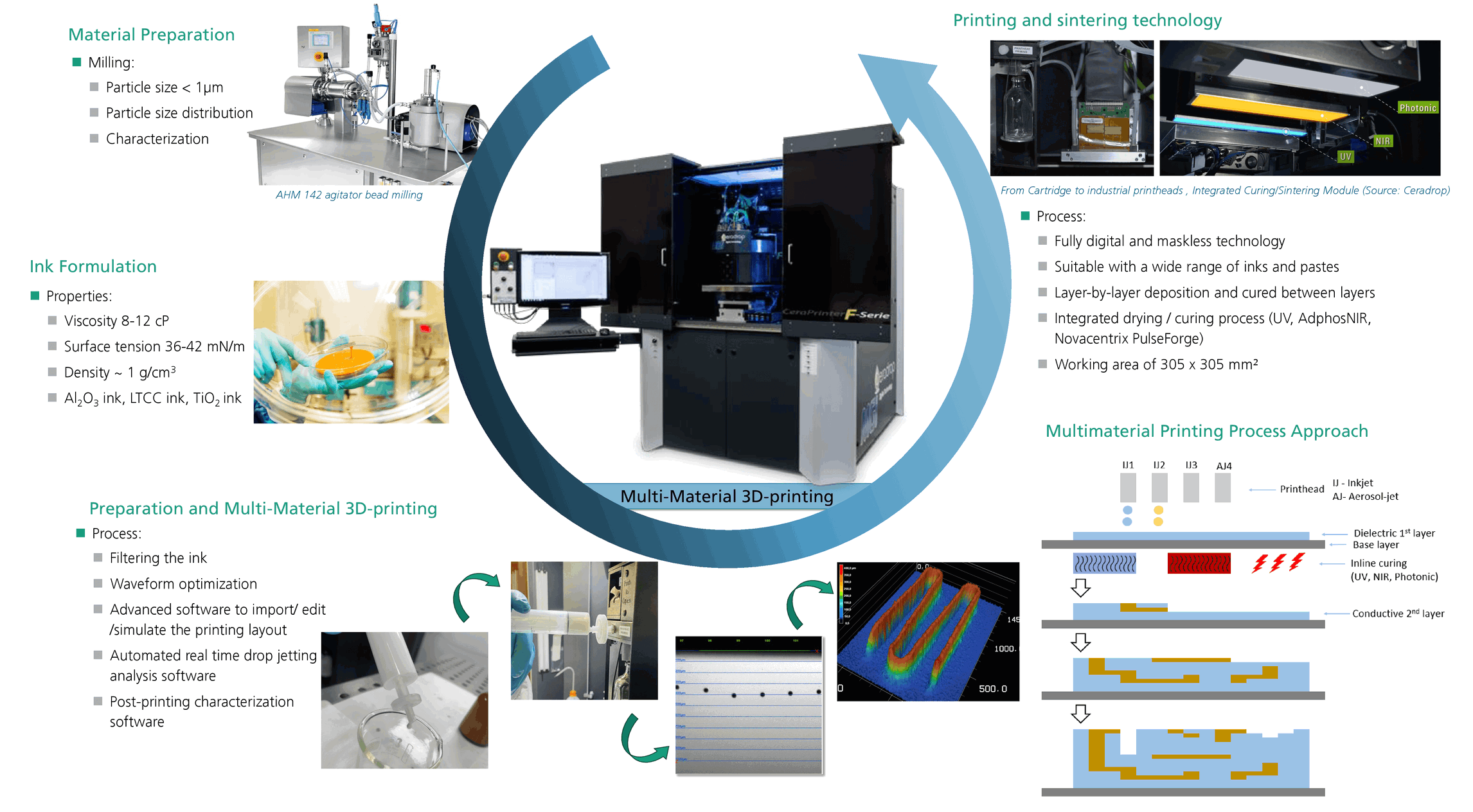

Printing and Sintering Technology

Integrated Drying & Curing modules (by Ceradrop)

Functional Multi-Material 3D-Printing and Sintering/curing in One Device

Dr.-Ing. Steffen Ziesche of Fraunhofer IKTS presents advancements in ceramic multilayer manufacturing to new heights in this insightful presentation.

Applications

- Designed for Advanced Digital Process Development in multidisciplinary fields such as LTCC multilayer ceramic components and printed electronic applications like: RF IDs, interconnection of chips, photodetectors, lenses, semiconductor printing, sensors, piezoelectric actuators and fuel cells

- Development of high-resolution structures suitable for applications in printed electronics, including both low and high-frequency devices

- Offering a range of services in collaboration with industry and scientific partners in 3D printed electronics

Highlights

- Up to four different printing heads for applying a wide range of functional inks

- Functional printing on low- and high-temperature substrates in flat and 3D geometries

- Fully integrated and synchronized post-treatment modules (UV, Adphos NIR, Novacentrix Pulseforge) for drying and curing printed layers

- Additive manufacturing technology with high-resolution structures for applications in electronics (low and high frequency), microsystem technology and sensor technology

LOPEC 2024 Poster Session Fraunhofer IKTS

Read More About the J.A.M.E.S Coin NFC on AME in 3D Ceramics

For the first time the J.A.M.E.S Coin Design is transformed into a new material and process concept. The Fraunhofer IKTS at Dresden used their process knowledge in additive ceramics to realize the NFC tag application.

By utilizing ceramics and the additive process to integrate conductive structures into the J.A.M.E.S coin's formfactor, we can unlock a range of material and process advantages. This approach offers improved thermal stability and radiofrequency capabilities, opening doors for future applications.

Related Articles

Nanotechnology In HealthTech – Biofunctional Coatings For Implantable Devices

Printed Circuit Structures: The Evolution Of Printed Circuit Boards

J.A.M.E.S And Friends Interview Series: Innovations In AME With Fraunhofer IKTS