Technology Insights

AME Publications

Academic Research

Long Term And Cryogenic Endurance Of FPC Interconnection Approaches

Long Term And Cryogenic Endurance Of FPC Interconnection Approaches

Apr 17, 2024

This technical Article is created by following Authors:

Alois Friedberger, Andreas Helwig Airbus CRT, Central R&T, Taufkirchen (Munich), Germany

Patrick Hornung Airbus Defence & Space, Ottobrunn (Munich), Germany

Acknowledgements:

We highly appreciate the support of Joao Marques from Fraunhofer IZM conducting several FPC joining processes .

Lopec 2024 Poster Session Functional Materials; Abstract Number: 100879

Motivation

Flexible Printed Circuits (fpc) Are Widely Used in Various Applications Ranging From Soleley Replacing Cables up to Advanced Sensing Systems With Integrated Circuits Inside the Fpc Foil

Wide Dimensional Range From Extremely Small as E.g. In Medical Implants up to Several Meters Long, As E.g. In Space Vehicles

Often, Fpcs Need to Be Electrically Connected to Each Other or to a Rigid Structure With Appropriate Contacts Pads.

What Kind of Substrate Material and Which Interconnection Technology Is Suited Best for Extremely Harsh Conditions?

Need for Endurance Investigations of Different Approaches to Create Such Mechanical and Electrical Interconnections.

Approaches

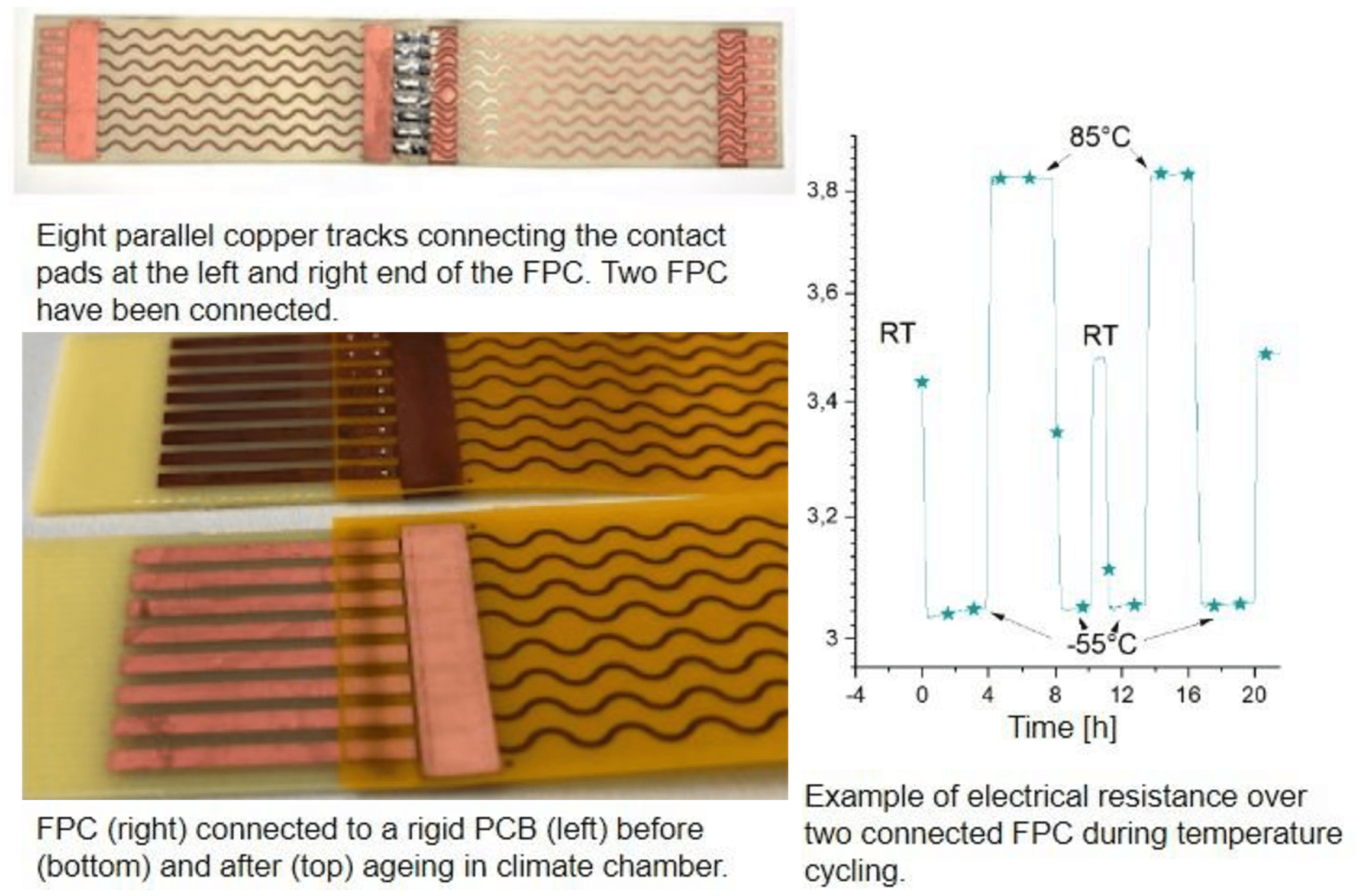

Polyimide (pi) and Polyethylenimine (pei) Foils as Substrates for Eight Parallel Copper Tracks Along These Fpcs.

Copper Contact Pads at Both Ends of the Fpcs

A) Fpc-Fpc Interconnection: Two Fpcs Connected by Placing Contact Area of One of Them Upside Down to the Contact Area of the Other Fpc

B) Fpc-Rigid Structure Interconnection: Fpc Interconnected to a Rigid Structure Represented by a Conventional Pcb With Copper Contact Pads

Mechanical and Electrical Joining Approaches: 1. Soldering, 2. Wedge Bonding, 3. Isotropically Conductive Adhesive (ica), 4. Anisotropically Conductive Adhesive (aca), 5. Anisotropically Conductive Film (acf), 6. Nanowiring

Results

- Wedge bonding failed (attributed to elastic nature of foil materials) --> not further tested

- > 650 fast thermo cycles from - 55°C to + 85°C with all samples:

- only 3 contact failures (all on one and the same ACF test coupon)

- 5000 hours climate ageing at 70°C, 85% rH:

- no failure of any contact

- Cryogenic temperature cycling for approx. 6 month including 5045 cycles from -170°C to +130°C:

- Except for three individual electrical contacts, all samples passed,

- Exception:

- PEI substrate all contacts failed - attributed to PEI brittleness at cryogenic temperatures

Conclusions

- "Standard" interconnection technologies provide stable electrical / mechanical contacts also for harsh environmental conditions as required by the aerospace industry.

- Performance at cryogenic temperature, as an even more demanding application scenario, necessitates the appropriate selection of a suitable substrate material.

Lopec 2024 Poster Session Functional Materials; Abstract Number: 100879

See Further Lopec 2024 Poster Session - Functional Meterials

Durability investigation of 3D printed electronics towards aeronautic-inspired environmental loads

by AIRBUS CRT and J.A.M.E.S GmbH

Related Articles

nScrypt

3 Likes

3 Likes

Fabrication And Microwave Characterization Of 3D Printed Transmission Lines

04.10.2024

Featured Partners

About Us

© 2025 J.A.M.E.S GmbH.