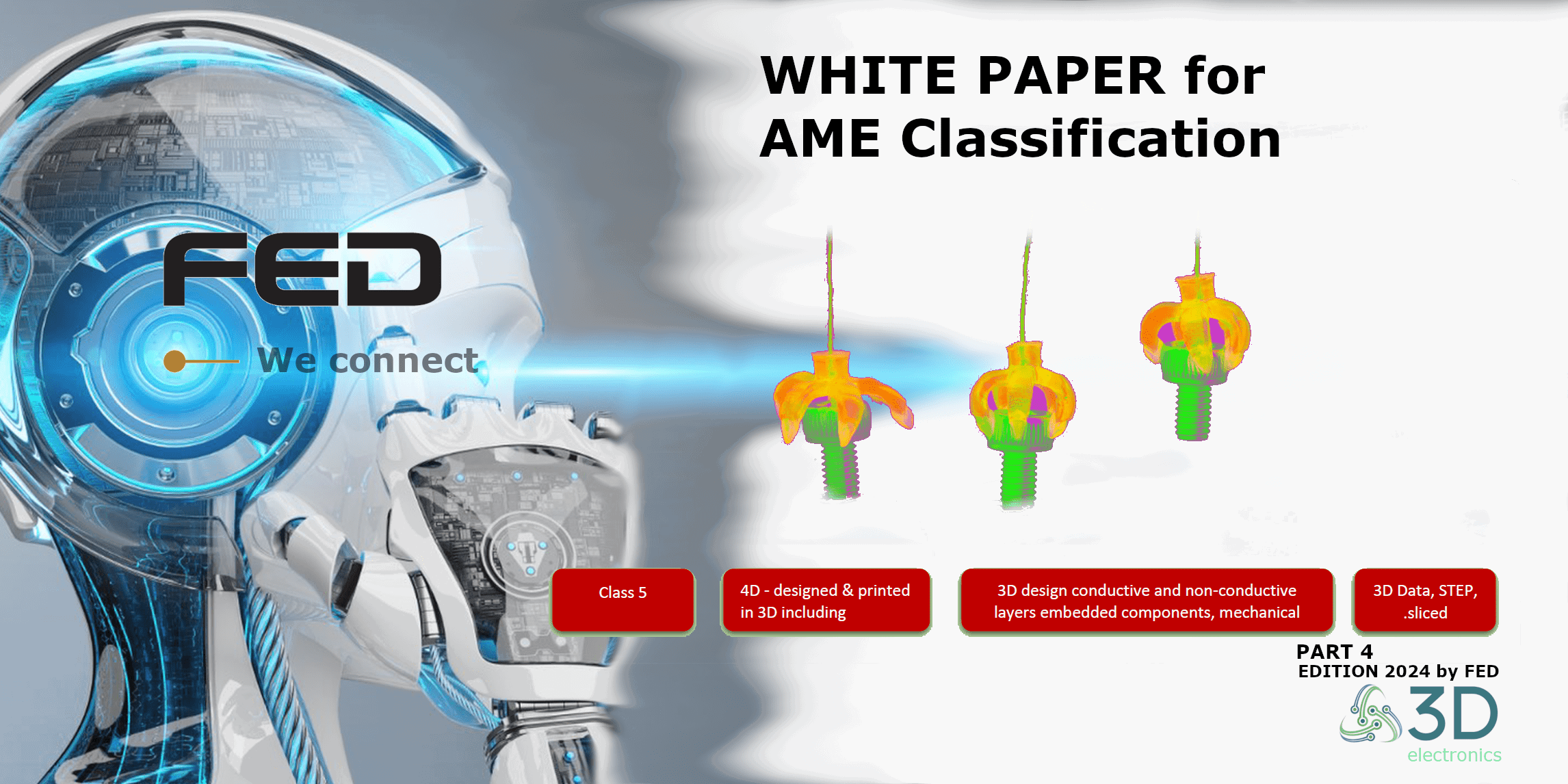

FED White Paper Edition 2024: Part 4 AME Classification (Class 5 (4D))

AME Class 5 and Overview of Manufacturing Technologies From the New Edition White Paper. Classification of Additive Manufacturing and 3D-Printing Processes for Electronics.

Table of Contents

Class 5 - Shape-Changing Solutions (4D)

“Class 5" defines the application of one or more functional layers without a carrier (substrate). This enables this technology to create products with a freely designable three-dimensional shape. As described in the previous classes, the additive layers can be applied using a wide variety of processes and technologies. Products in "Class 5" are referred to as 4D-printed parts or "4D printing". The fourth dimension is described as the time factor. The external stimulation of the 3D-printed part and a specific timeframe allows the part to change its shape.

In Addition to Standard 3D Printing

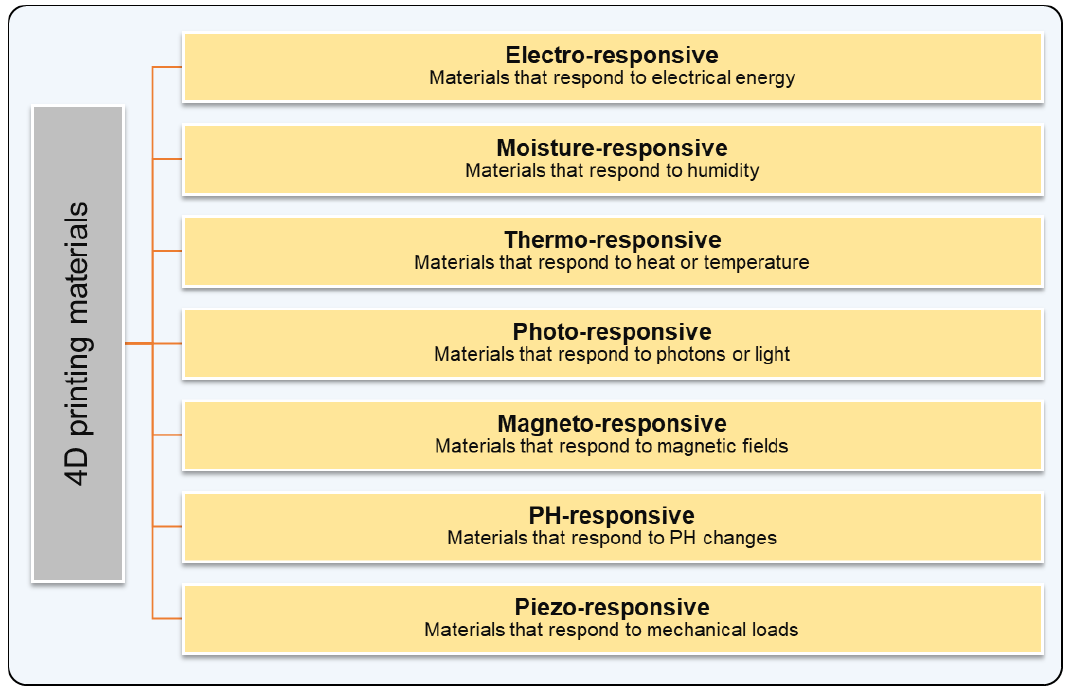

The starting point for this technology is polymers with unique properties that classify them as "intelligent materials." These materials, often referred to as "smart compounds," have the ability to change shape in response to external stimuli. "Class 5" objects therefore differ significantly from traditional "Class 1 to 4" 3D-printed objects.

Currently, there are only a few known electronic components classified as “Class 5” components. The primary advantage of this method is the ability to create electrical functionality triggered by environmental or external stimuli.

This breakthrough opens a wide range of new electrical and electromechanical applications. At the same time, it enables the manufacture and utilization of extremely small electromechanical components and applications.

Printing Methods for 4D Technology

The technology of 4D printing is relatively new compared to the previously mentioned processes (at the time of writing this “White Paper”).For this reason, the selection of printing processes is smaller. The following printing processes are available:

-

Fused Deposition Modeling (FDM):The printing material is melted in an extruder and extruded through a nozzle. The material is applied in layers.

-

Stereolithography (SLA): A light-curing material is cured in thin layers by a laser or UV light. The layer-by-layer curing process bonds the material into a polymer network.

-

PolyJet: A print head applies tiny droplets of a photopolymer to a surface, which are immediately cured with UV light.

Application Examples for 4D: Class 5

4D technology opens a wide range of new possibilities in production and use. Here are a few examples:

Examples of Additively Manufactured Electronics for Class 5:

- Transformation of the shape due to temperature change, shape memory alloy, etc.

- Volume reduction through folding (e.g., medical technology)

- Closing/opening of valves (e.g., microdosing, temperature-dependent flow, etc.)

- Contacts that open and close under certain conditions

- Lifting elements (combination of rigid and memory properties)

- Independent assembly/folding in response to stimuli

- Combination of shape memory materials with rigid materials for robotics, such as autonomous grippers

Examples of printed systems that change their shape.

Overview of Manufacturing Technologies

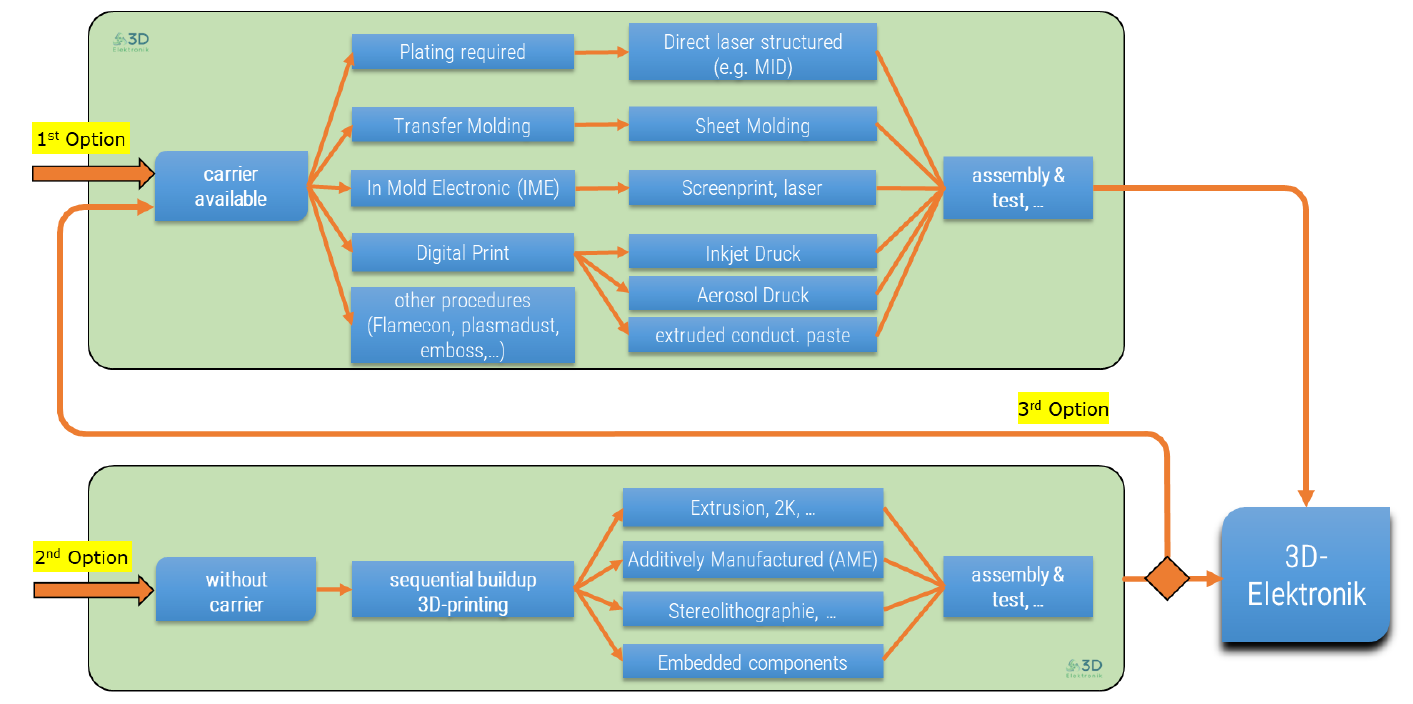

The simplified illustration is intended to help visualize the different production technologies and the basic production processes.

Simplified depiction of production technologies and process steps.

Additional technologies are not excluded for the manufacturing and assembly of end products. Subtractive technologies, such as milling for surface optimization, are also conceivable in order to achieve an optimal overall process chain.

Digital Printing and Environmental Goals (European Green Deal)

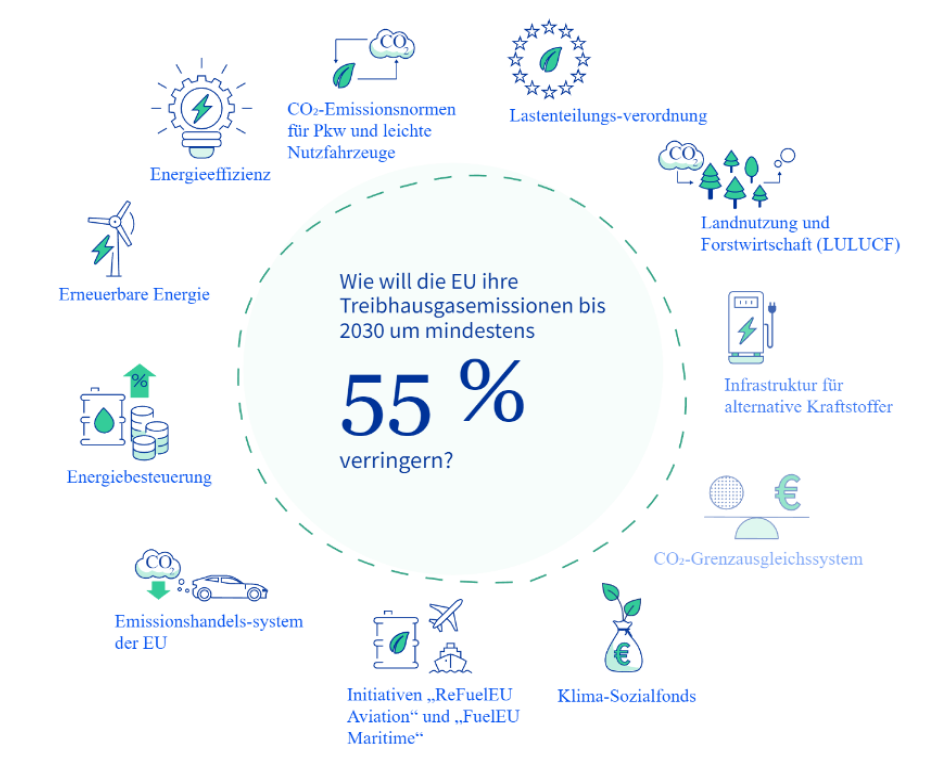

An important aspect when evaluating AM should be a look at the current European and international targets for greenhouse gas emissions. The declared goal of the European Union is to reduce greenhouse gas emissions by 55% by 2030 compared to 2019. The EU guidelines specifically regulate the steps in this direction through the so-called CSRD (Corporate Sustainability Reporting Directive).

In the first step, the requirement will apply to large companies from January 1, 2024, and to Small and Medium Enterprises (SMEs) and capital market-oriented companies from January 1, 2026. SMEs can be exempted from the EU directive ("opt-out") for a transitional period until 2028.

The potential and advantages of AM - savings in materials, energy consumption, and transportation - can help achieve corresponding corporate goals.

Various laws are intended to more than halve greenhouse gas emissions in the EU (Source: European Council; European Green Deal: ‘Fit for 55’).

Growth of Additive Manufacturing (AM)

Regardless of which manufacturing industry is examined more closely, high growth rates are attributed to the principles of AM in each of them. It is possible to realize new and previously unknown product features and properties with the processes known today.

As processes and materials continue to develop constantly, it will be possible to design and construct products using new and potentially yet-to-be-developed processes, tools, and data formats. This effect will further accelerate the growth of AM processes.

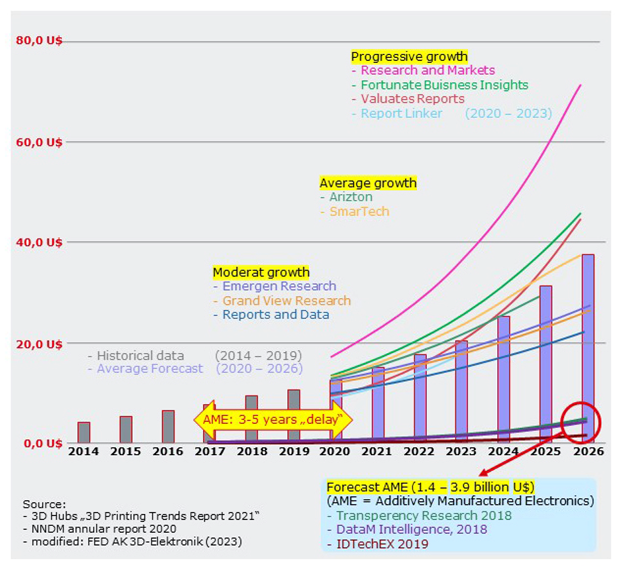

Market forecast for 3D printing

The AM Trend Report forecasts a doubling of production in the next five years (Source: Hubs, Additive Manufacturing Trend Report 2021)

In the AM Trend Report shown on page 21, market observers forecast average growth of 21% in 2021. These are AM processes that are provided by the 1.504 mechanical engineering companies surveyed for the report. Another forecast estimates that the market will more than double in the next five years.

The prerequisite for the spread of AM are powerful and easy-to-use software tools and design-chain. All components are created virtually with the help of these design tool. Using existing tools and new tools yet to be developed, a so-called "digital twin" is created from the data set of the new component, which serves as the basis for various computer-aided simulations.

This data set is the basis for the production-relevant data. One feature of this principle is, that this approach can be used across all industries and tools. This makes it possible to further accelerate the design of AM components.

FED Working Group for 3D Electronics: The People and Motivation Behind It

Over more than five years of activity, the FED working group on 3D electronics frequently encountered questions about what is actually meant by specific 3D solutions or printing principles and how these technologies could be applied in electronics production. After jointly analyzing the initial situation and the potential of 3D printing, the decision was made to work on this specific topic and present it to the PCB design community and industry.

First and foremost, we would like to thank the Fachverband Elektronikdesign und Fertigung e. V. (FED), which has provided us with outstanding support in our work. The fruitful collaboration and regular exchanges with various universities, research institutes, and companies have propelled the project forward and enriched our group with valuable knowledge. We would also like to extend our gratitude to our colleagues from the 3D electronics working group, who developed this classification in their free time.

The FED working group on 3D electronics prepares and disseminates knowledge about these new processes for its members, interested experts, and now the J.A.M.E.S community.

FED Working Group for 3D Electronics Members in 2023

Explore the AME Classification Overview

The FED Working Group for 3D Electronics presents the five classes of 3D-printed electronics processes.

Related Articles

RI.SE And NNDM - Drive Sustainability And Disruptive Innovation

Lithoz Combine Metal & Ceramic By Multi-material 3D Printingj And Join At RAPID TCT

Design And Fabrication Of A Plastic-Free Antenna On A Sustainable Chitosan Substrate