XTPL's Innovative High-Resolution Dispensing Technology For Advanced Electronics Manufacturing

XTPL team presents a comprehensive article concerning its own, disruptive technological solutions for extremely high-resolution dispensing of functional materials for manufacturing the next generation of electronics.

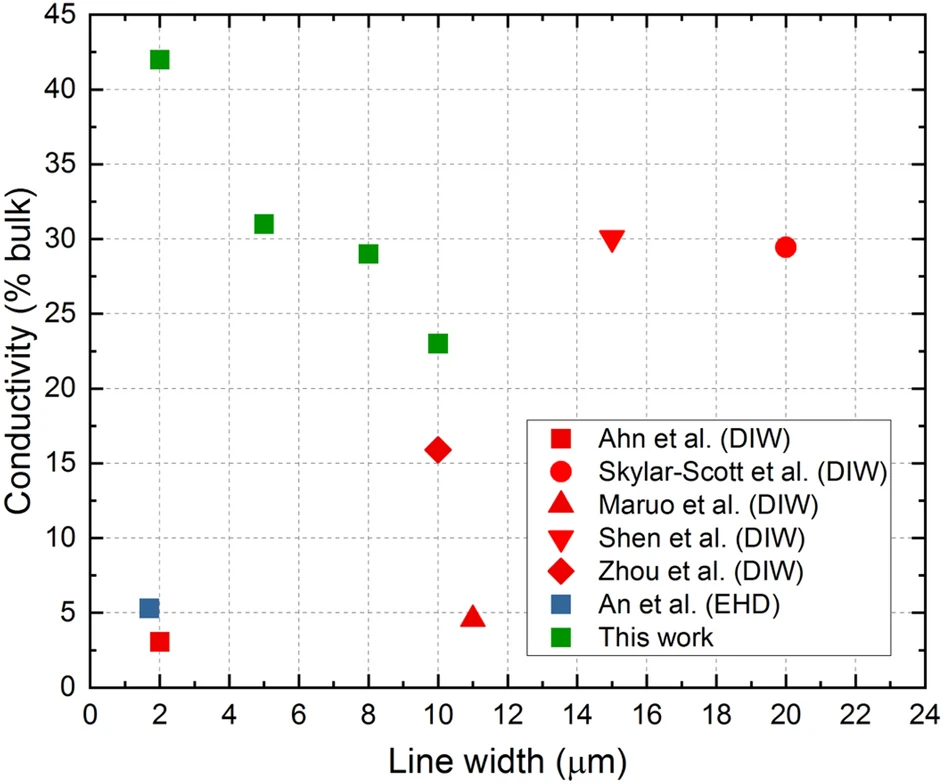

Additive manufacturing has emerged as a flexible option for producing and prototyping cutting-edge microelectronic devices, such as biomedical equipment, solar cells, IoT sensors, batteries, MEMS devices, and displays. The recent development of 2D planar structures and free-standing 3D architectures in printing techniques has remarkably advanced the field. Direct writing techniques have gained attention due to their ability to print features of micrometre size without the risk of damaging electronic components. However, there is a crucial missing piece in the puzzle: an intermediate technology that enables the printing of both conductive and insulating structures on composite substrates that vary in material properties and topography. The printed features must align closely with the substrate profile to ensure mechanical stability and efficient encapsulation for further use. This is particularly essential when additive manufacturing is used for fabricating or repairing modern microelectronic devices, like repairing defects in OLED displays or generating electrical connections in µLED arrays.

Read the whole article

Related Articles

FED White Paper Edition 2024 - PART 2 - AME Class 1 And Class 2

University Of Stuttgart & KIT Test Delta Printing And XTPL Tech For New Application

Enhancing Electrical High-frequency Performance By An Optimized Additive Manufacturing Strategy

FED White Paper Edition 2024 - Part 5 - Design Tools For 3D Electronics