How Micro-AM Advances Precision Medical Devices

Microscopic Marvels

Recent advances in precision and accuracy with micro-additive manufacturing (µAM) technology have significantly expanded its applications. Where previous limitations in precision and repeatability rendered µAM unsuitable for certain uses, today's innovations have made it both faster and viable for commercial applications.

However, µAM remains somewhat restricted as most parts produced are primarily plastic. This article explores how this limitation can be overcome and what it means for medical applications, particularly in microfluidic devices, microneedle arrays, and miniaturized medical tools.

Why µAM?

µAM offers several significant advantages in medical applications due to its unparalleled precision and versatility. One of the primary benefits is its ability to produce highly intricate and complex geometries at a microscale, which is essential for creating devices with the fine details required for some medical applications.

µAM enables the production of detailed structures with high accuracy, which would be challenging to achieve with traditional manufacturing techniques.

In addition, µAM is advantageous due to the fact that in more recent times, materials have become available for use on µAM machines that have passed the relevant tests for:

- Skin irritation

- Sensitization

- Toxicity, cytotoxicity

- Pyrogenicity and in vitro hemolysis

They are also sterilisable and are permissible for non-implantable medical applications. µAM also facilitates the customization of devices to fit specific patient needs, leading to more personalized and effective treatments. The ability to rapidly prototype and iterate designs also speeds up the development process, allowing for faster innovation and time-to-market for new medical technologies.

µAM plays a crucial role in the consolidation of part production by enabling the integration of multiple components into a single build, thus eliminating the need for complex assembly processes.

This capability is particularly beneficial in medical applications, where the precision and reliability of devices are paramount. It not only enhances the structural integrity and performance of devices but also reduces the risk of leaks or failures that might occur at assembly junctions.

This consolidation of parts streamlines manufacturing processes, reduces production costs, and accelerates the time-to-market for innovative medical devices.

Applications and Enhanced Functionality

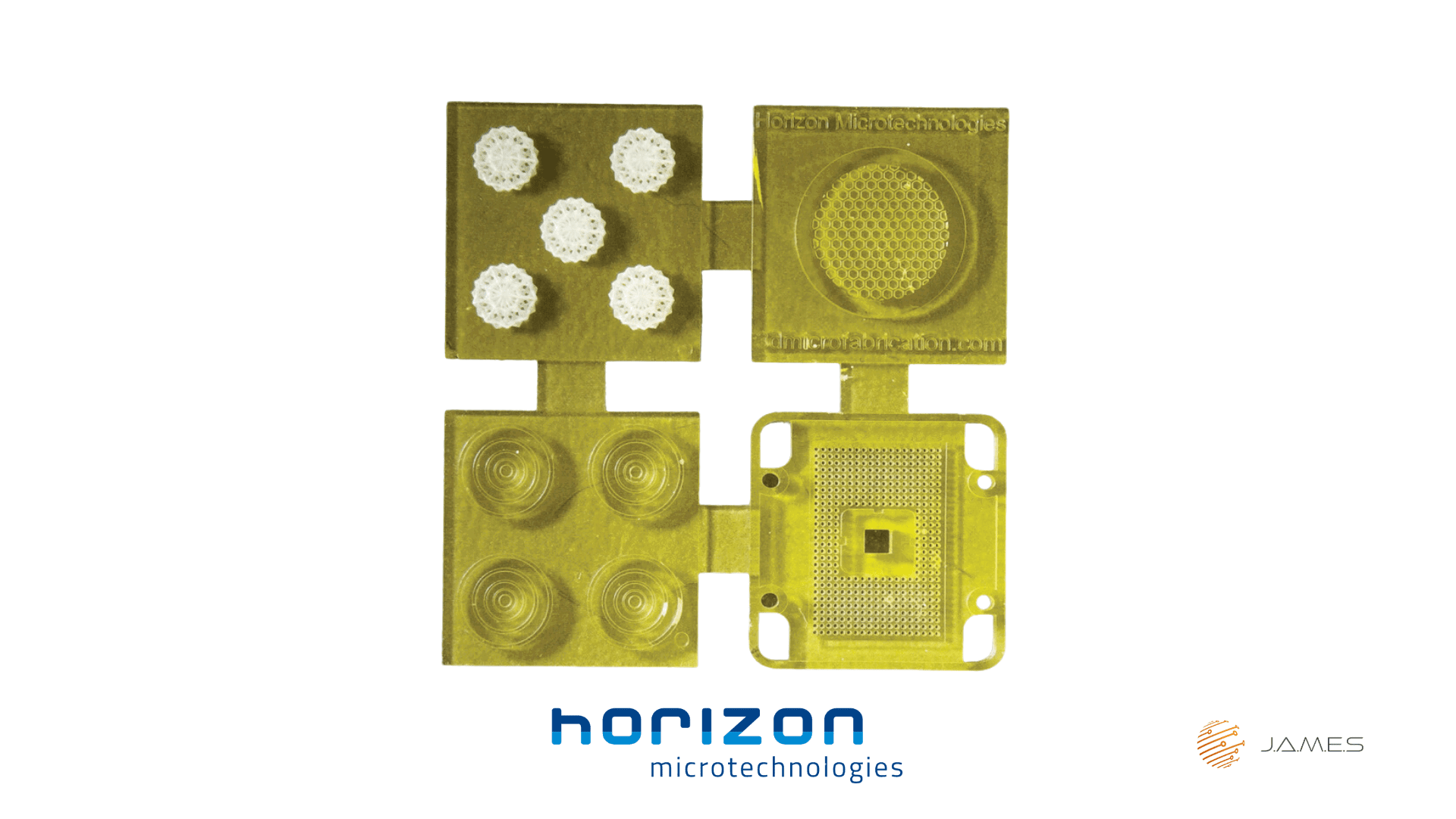

Horizon Microtechnologies integrates the design and development of 3D microparts with a complete microfabrication production process.

The company combines its µAM expertise with proprietary coating technologies, including:

- Non-metallic conductive (HMT-Conductive)

- Environmentally resistant (HMT-Protect)

- Metallic (HMT-Metal)

These coatings enhance the functionality of microstructures, including plastics and ceramics, driving innovation in applications such as microfluidics, microneedles, and miniaturized surgical tools.

A Micro-Needle

A micro-needle fabricated by Horizon Microtechnologies and designed by Dr. Jufan Zhang from University College Dublin, Ireland.

Microfluidics

The traditional fabrication of microfluidic devices is often cumbersome due to the need for multiple complex and precise processes, such as photolithography, etching, injection molding, imprinting, and bonding of different materials. These processes are not only time-consuming but also prone to errors and misalignments. In the case of bonding, there is often an inability to withstand high pressure.

These conventional methods require cleanroom environments and sophisticated equipment to achieve the necessary microscale features, making production costly and less accessible.

Horizon offers a streamlined solution using µAM, integrating the entire fabrication process into a single step followed by coating. This approach enables the precise design and printing of intricate microfluidic structures in a single build, reducing production time and complexity. It supports rapid prototyping and customization of designs, enhancing efficiency and innovation in microfluidic device development.

Additionally, µAM facilitates the prototyping of short-run injection molding inserts, reducing product development timelines and accelerating time to market.

Furthermore, Horizon’s HMT-Protect coating can create a closed layer on microfluidic channel surfaces, whether they are 3D-printed, machined, or injection-molded.

This separation between the liquid in the channel and the substrate material is particularly advantageous for enhancing fluid flow in samples ranging from microliters to femtoliters.

It effectively prevents cross-contamination, which is crucial for maintaining the integrity and accuracy of results in microfluidic applications where capillary forces or surface tension drive liquid movement.

For pressure-driven microfluidics, bonded devices are often inappropriate due to their inability to withstand high pressure, as mentioned above, making µAM a preferred production technology.

Micro-Needles

The traditional method of fabricating microneedles, such as those used for transdermal drug delivery, typically involves complex, labor-intensive processes, including lithography (which also requires costly capital equipment), etching, molding, micro-machining, and laser drilling. These methods can be time-consuming, costly, and difficult to scale. Moreover, they often lack the precision needed to create microneedles with optimal geometries for consistent drug delivery, leading to variability in performance and effectiveness.

Through the utilization of µAM technology, Horizon provides a solution characterized by precision, scalability, and cost-effectiveness. This technology enables the direct fabrication of microneedles featuring intricate designs and precise dimensions, ensuring consistent quality and performance.

Horizon has successfully printed microneedles with internal channels as small as 100 μm. Additionally, the technology allows for the introduction of precise, miniature holes in the needle’s side walls.

Furthermore, Horizon offers coatings such as:

- HMT-Conductive for applications requiring electrical conductivity and sensing.

- HMT-Protect to optimize fluid flow and prevent cross-contamination between the liquid and the plastic substrate.

These enhancements are crucial for maintaining the integrity and accuracy of fluid handling in microfluidic and sensing applications.

Miniaturized Surgical Devices

Horizon has identified the use of µAM as crucial for creating miniaturized surgical instruments due to its ability to consolidate parts and reduce assembly efforts.

Traditional manufacturing methods often involve the production and assembly of numerous small, intricate components, which can be labor-intensive and prone to errors.

µAM enables the production of complex, integrated instruments in a single step, minimizing the need for assembly and thereby reducing the risk of misalignment or mechanical failure. This integration not only streamlines the production process but also enhances the reliability of the instruments.

Webinar by Andreas Frölich

Horizon Microtechnologies’ CEO, Andreas Frölich, presented on the manufacturing of millimeter wave (mm-wave) components using additive manufacturing and coating technologies.

Related Articles

Optimizing Component Design Via Coated Micro-AM Parts For Exacting Precision Engineering And Semi-Conductor Applications

Horizon Microtechnologies Presents "D-band Horn Antenna" At EuMW 2024

Voltera NOVA Applications: Printed Silver Tattoo Electrodes And Copper RFID Tag

FED White Paper Edition 2024 - Part 5 - Design Tools For 3D Electronics

FED Working Group For 3D Electronics - New English White Paper Edition 2024