Where Is 3D Printing Used?

In recent years, 3D-printing has made an essential impact on global industries, expanding their manufacturing and designing possibilities. In fact, they provide great versatility regarding the small-scale prototyping and significant industrial productions. This article will discuss the wide application of 3D-printing technologies and its impact on global industries.

1. Healthcare

One of the fields where 3D-printing has made the most significant progress is healthcare, namely the manufacturing of customised prosthesis for patients, orthopaedic implants, and surgical tools. Thus, the technologies enabled the improvement of patients’ outcomes, as well as their high levels of satisfaction. What is more, the development of bio-printing allowed the printing of living issues and organs, meaning that it may one day be possible to print internal organs to replace damaged and preserve biological ones.

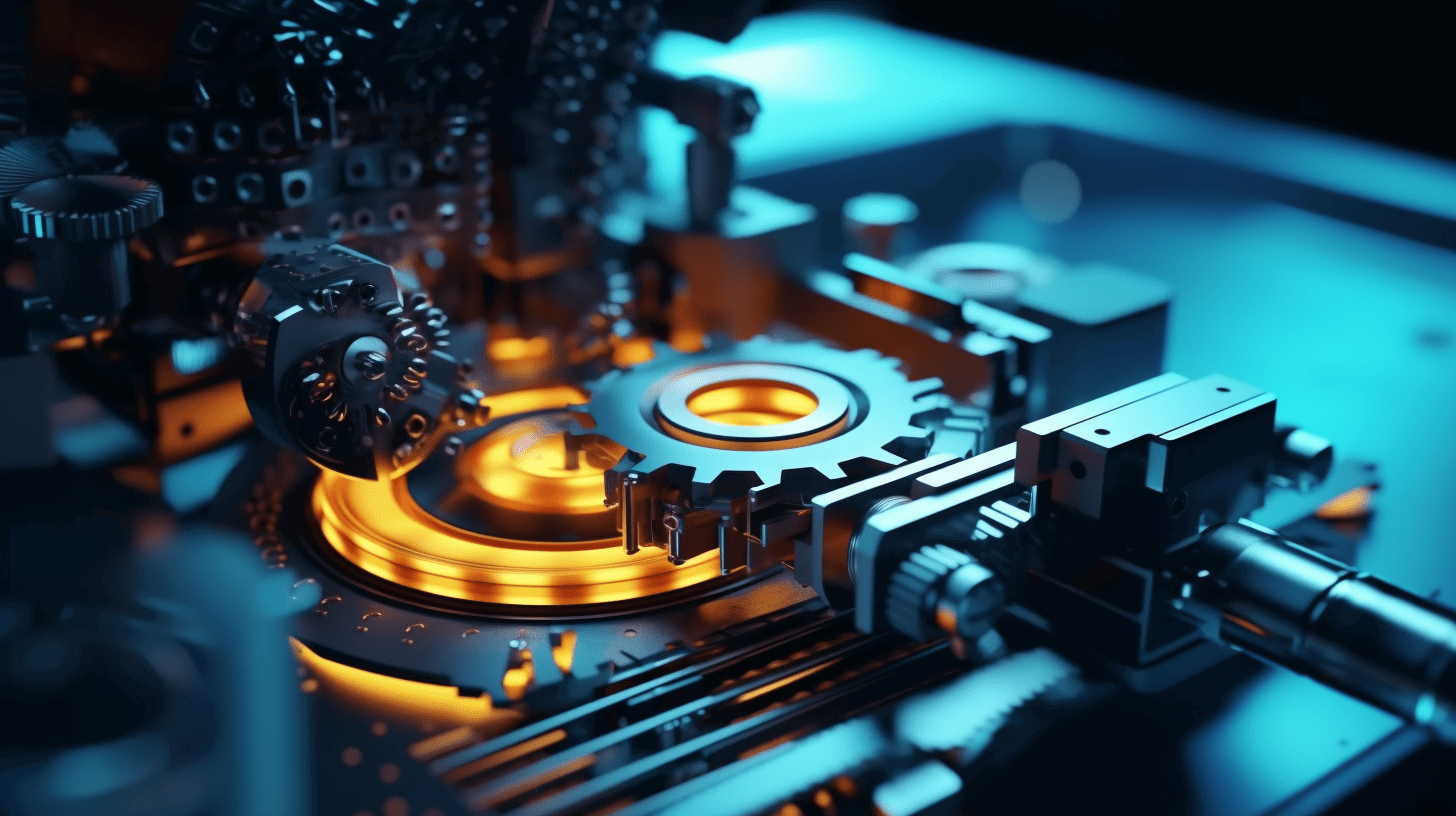

2. Aerospace and Automotive

In the automotive and aerospace industries, 3D printing technology is radically transforming the way parts are developed for ready-made use. 3D printing provides engineers with the ability to engineer complex geometries that are difficult or impossible (expensive) to produce by conventional means, boosting a car's performance whilst reducing its weight-effective design. Among the many advantages of 3D-printing are quick turnaround times, on-site customization (for local contract manufacturers and dealers) as well as weight-savings that enhance fuel economy or reduce emissions. Using additive manufacturing means that more specific tools and fixtures can be created which reduces the need for long lead times, making it a cheaper option. The same technology offers the precision necessary for many of aerospace's stringent part requirements, improving aircraft performance and safety. This technology enables lightweight structures, complex assemblies and material innovation to produce more efficient aircraft with greater performance. Examples of real-world applications are complex turbine blades, the most efficient engine components and complex parts for space craft. 3D printing has been changing the way we look at innovation for years now, but there are still new design and manufacturing levels to be discovered as materials and technology improve. Though 3D printing comes with its own set of challenges, such as lower production speeds and issues regarding quality control, recent advancements in research are addressing these problems to the extent that large-scale manufacturing is becoming more possible. In the rapidly-evolving automotive and aerospace sectors, engineers must adopt 3D printing to remain competitive in terms of innovation.

3. Architecture and Construction

Nowadays, film architects and engineers using 3D printing with intricate scale models have made such extensive visualization of their design idea easy for communication. To give a further example from the construction: The use of 3D printing techniques in building components including walls and structural elements is greatly increasing efficiency (and decreasing cost). Furthermore, this method of construction could be a game changer by reducing on-site assembly times while also cutting back on material waste in the building industry.

4. Education and Research

3D printing or additive manufacturing is rapidly being adopted in research and academia, exciting scientists researchers and educators by the new ways problems can be solved using designs. In education, it is so much more than a novelty; this tool enhances learning across numerous disciplines and allows kids to have some hands-on experience with STEM concepts and arts projects. Because 3D printing enables protoyping ideas within hours it is a valuable tool for engineering and design (and also great in special needs education; print your own teaching aids). The technology is also transforming research, as rapid prototyping allows for quickly customized and cutting-edge investigations of complex structures, such as in materials science and medical sciences. For example, in medical research 3D printing is being used to build tissue scaffolds and custom medical equipment that fits the individual patient- leading to better outcomes. Aerospace and automotive have utilized the fabrication of intricate shapes with a low-weight shape-out, by engineering complex parts whereby there is increased demand for high-performance even weight reduction. Although there are obstacles to overcome - such as material constraints, quality control and telecommunications bandwidth limits- the possibilities for research cross-fertilization and innovative discovery appear limitless. Harward, MIT and the university of Nottingham are pioneers on new material and applications Front (From bioprinting to astrorage) This technology also supports global research, enabling researchers across the world to work together on common issues and break new ground. Moving ahead, we can witness its contributions to Education and Research as 3D printing progresses further thus educating the future innovators who are responsible for technologically driving our industries.

Conclusion

3D printing is taking off and will increase its potential of what it can do for mankind -- its ability to scale exponentially, with a very low barrier to entry or economics that pretty much parallel semiconductors. In healthcare and aerospace, education to fashion this new technology has broken the barriers of traditional manufacturing techniques while significantly increasing design freedom potential, customization options as well as innovative visions. 3D printing, as it innovates and moves more mainstream, is poised to affect even further industries in the near future. Hold onto your hats - it is a brave new, unbounded world with game-changing technology like this.