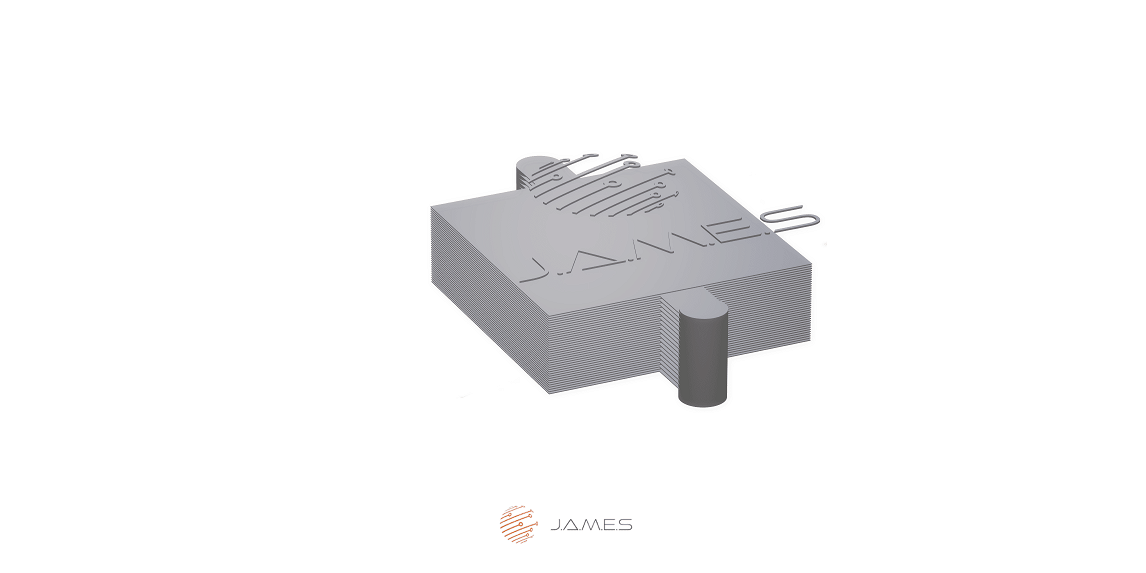

AME Coils And Caps Test Coupon - Single Elements

Design

A first design is finished, a complete explanation of the targeted functionality is included, and the targeted printer technology has been provided. This AME design also provides a model which is proven to fulfill the targeted functionality.

This artice gives a detailed insight of the J.A.M.E.S AME Coils and Caps Test Coupon.

AME-Workflow from design, Preperation of a print job, realisation up to verification and test.

By this example an optimization workflow will be visible to minimize the difference between simulaiton and measured reality of AME designs.

Several challenges have to be taken into account - for the 3D printing process the following desings represent a clear seperation from traditional designs of a printed circuit board by full-3D wiring.

The realizations of such structures have to achieve a acceptable conductivity in all 3dimensional axis properly.

The electric functionality itself represent a clear key performance indicator about design rules, accuracy, reproducability and additively handling of multi materials in a printer process.

Zooming in

Additive manufacturing electronics stands for the ability to realize full 3D-structures for electrification and functionalisation of new components.

This is a major difference in comparison to traditional PCB-manufacturing.

- PCB's reach out a z-axis conductivity by metalized VIAs.

- AME doesn't need VIAs, cause of full 3D-design which is enabled by slicing and additive process to manage a z-axis conductivity.

Download to Read More

Design Views of Five Single Ame-Capacitor Elements in the Coils and Caps Coupon

Ame Capacitor C1

Ame Capacitor C2

Ame Capacitor C3

Ame Capacitor C4

Ame Capacitor C5

Design Views of Eight Single Ame-Coil Elements in the Coils and Caps Coupon

Ame Coil L1

Ame Coil L2

Ame Coil L3

Ame Coil L4

Ame Coil L5

Ame Coil L6

Ame Coil L7

Ame Coil L8

Example by Using Cst Studio Suite

The following example for a passive element simulation with CST Suite is performed with a constant dielectric constant of 2.79.

- In general the material parameters show variations over frequency.

- To perform an accurate simulation for AME-functional elements is is essential to have a detailed knowledge about the materail behaviour.

for more information about CST Studio Suite have a look to the J.A.M.E.S Webinar

Cst Suite Models for Ame Coils and Capacitors for Download

Example of a Coupon Capacitor Design

AME design ability can perform benefits when miniaturication, integration and increase of functionalisation, like RF performance is important.

AME C1 design 1.42nF in comparison to a COTS component 1400 pF Multilayer Ceramic Capacitor MLCC by KEMET

The existing portfolio of COTS compontents is extremely hudge and charactericed for mass production.

Outlook and Perspective for 3d-Ame-Printed Lumped Elements

J.A.M.E.S would like to give an outlook about what's next for this kind of AME-usecase.

Related Articles

Witnessing The Future Of 3D Printing Electronics With FPM-Trinity

First Community-Centric Collaboration In Sustainable Manufacturing