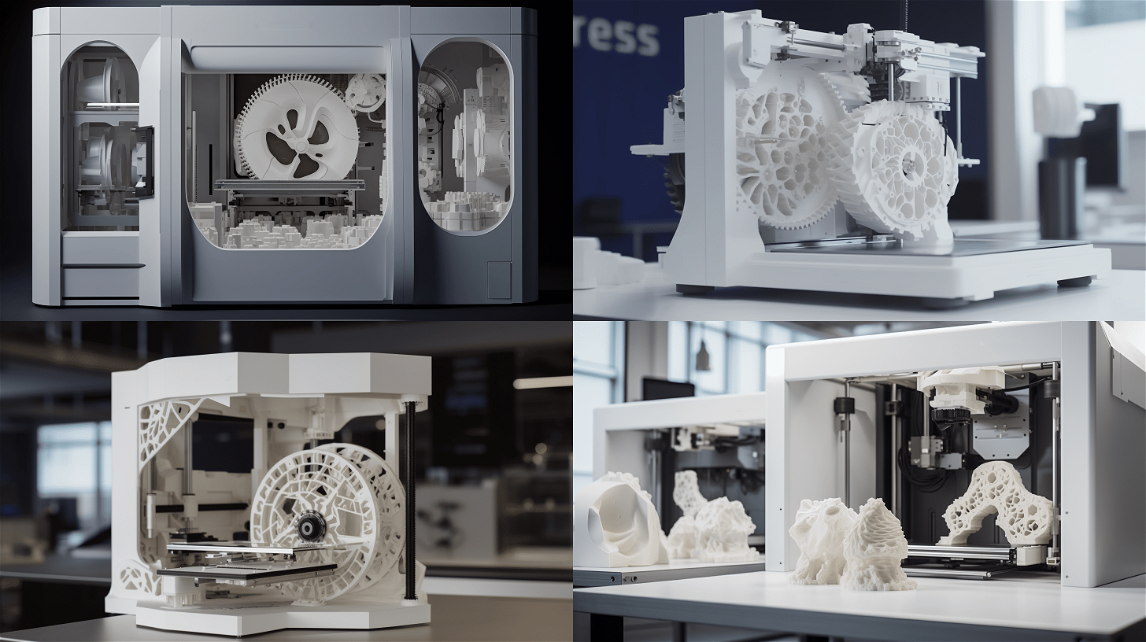

Exploring The Different Processes In 3D Printing

3D printing is a groundbreaking technology that has revolutionized the manufacturing industry, allowing for the creation of complex objects with intricate geometries and design features. There are several different processes involved in 3D printing, each with its own unique advantages and disadvantages. In this article, we will explore the various methods used in 3D printing.

Fused Deposition Modeling (FDM)

FDM is one of the most common 3D printing processes. It consists of heating a thermoplastic filament to its melting point, and then extruding the molten material layer by layer onto an object. FDM is one of the most cost-effective, fastest and versatile 3D printing technologies used for prototyping in the production process.

Stereolithography (SLA)

SLA is a type of 3D printing which cures liquid resin using ultraviolet light (photopolymerization) to craft an object. This is done by using UV lasers to cure a light-sensitive resin layer-by-layer, leading to an object of high detail finish and precision. Industries including jewelry, dentistry and medical equipment production that rely on SLA techniques by large numbers are commonplace.

Selective Laser Sintering (SLS)

SLS is a 3D printing technique that employs lasers to fabricate objects using powdered materials, primarily thermoplastics like nylon. The process involves a laser selectively bonding the powder material layer by layer, resulting in a robust and superior-quality product. SLS is widespread in the aerospace and automotive industries because it can build strong, lightweight parts.

Digital Light Processing (DLP)

DLP is a 3D printing process that uses a projector to make solid objects out of liquid photopolymer resin. It works by projecting ultraviolet light onto each layer of resin, which hardens it into the intended object. Meanwhile, DLP has become popular specifically in dental and the jewelry sectors once its speed becomes comparable to SLA with no loss of accuracy.

Binder Jetting

Binder Jetting: a 3D print process that applies alternating layers of powder material with the addition of a binder in particular sections to build up an object. This is a method which also delivers larger objects at relatively quickly and cost-effective manner, making it quite popular in the field of architecture & construction.

3D printing is a complex technology and involves various procedures that possess distinct advantages and limitations. The choice of the suitable process for 3D printing depends on the purpose of use and the desirable properties required in the end product.