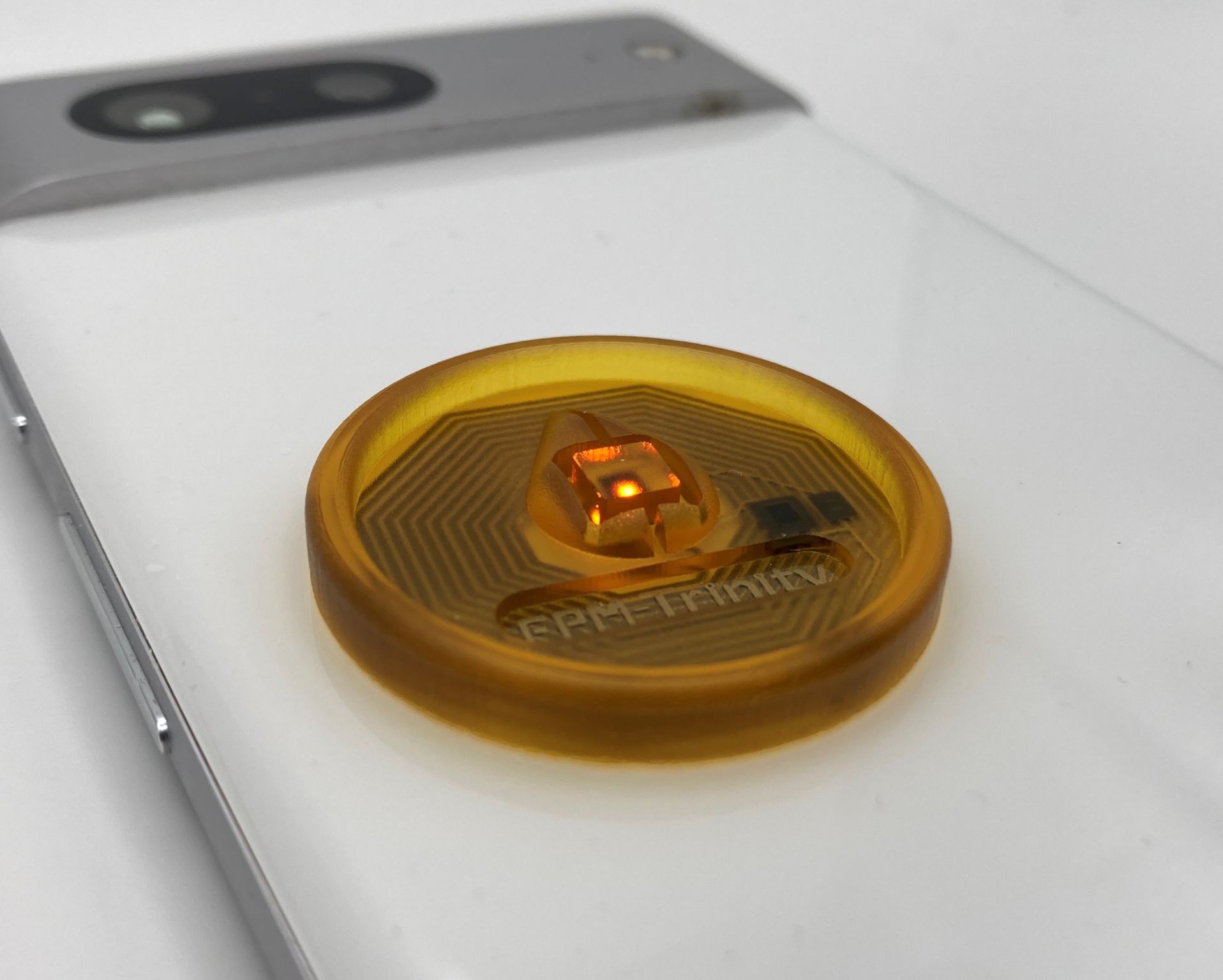

FPM-Trinity Coin

FUJI has refined the J.A.M.E.S coin design using their FPM-Trinity printer. This article explores the technical capabilities, design flexibility, performance quality, and future potential of this innovative printing technology.

Watch the FUJI Coin Model

Technical Comparison

The FPM-Trinity excels in creating boards with mounted components, allowing immediate analysis of functionality. This rapid feedback outperforms competitive machines, enabling swift adjustments and improvements.

Design Adaptations

Under current design rules, the FPM-Trinity restricts circuits to 0, 45, and 90 degrees for reliability. However, this constraint is necessary for testing more complex designs like circles, pushing the boundaries of innovation and reliability in coin design.

Performance and Quality

The FPM-Trinity's ability to print resin post the pick-and-place process ensures coins are a single, cohesive module. This eliminates the need for separate parts, enhancing durability and integrity. The consistency and quality of each coin are unmatched, thanks to this integrated approach.

Innovative Features

One standout feature is the FPM-Trinity’s roller mechanism, which maintains a flat surface despite varying component heights. This innovation ensures circuit boards closely match CAD designs, providing precision and reliability in every print.

Future Implications

The FPM-Trinity introduces two significant advancements. First, it enables the creation of 3D circuit boards, stacking components to reduce weight and XY area compared to traditional PCBs. Second, its fast prototyping capability allows for the production of mounted component boards within a day, accelerating proof of concept (PoC) and driving business growth.

FUJI’s FPM-Trinity not only adapts the original J.A.M.E.S coin design but also elevates it, setting new standards in the industry for technical excellence, design innovation, and future growth.

Comments

Related Articles

Rapid Estimation Method Of Dk & Df Parameters For AME Materials